- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200 KG

-

Power (kW):

-

5.5

-

Keywords:

-

cnc Door Stile Mullion Shape Milling Wooden Door Panel Shaping Machine

-

Power:

-

5.5kw

-

Max.working length:

-

2500mm

-

Max.working width:

-

adjustable

-

Max.working thickness:

-

100mm

-

Max. processing height (curve):

-

110mm

-

Max. processing arc (curve):

-

120mm

-

Working desk size:

-

2500*320mm

-

Spindle speed:

-

9000r/min

-

Spindle diameter:

-

35/40mm

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

NEWEEK

-

Machine Type:

-

wood milling machine

-

Weight (KG):

-

1200 KG

-

Power (kW):

-

5.5

-

Keywords:

-

cnc Door Stile Mullion Shape Milling Wooden Door Panel Shaping Machine

-

Power:

-

5.5kw

-

Max.working length:

-

2500mm

-

Max.working width:

-

adjustable

-

Max.working thickness:

-

100mm

-

Max. processing height (curve):

-

110mm

-

Max. processing arc (curve):

-

120mm

-

Working desk size:

-

2500*320mm

-

Spindle speed:

-

9000r/min

-

Spindle diameter:

-

35/40mm

Products Description

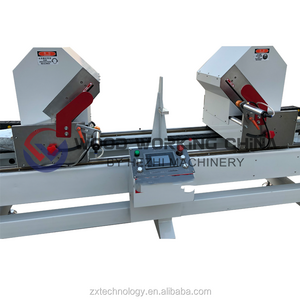

NEWEEK Industrial linear and curve spindle moulder for furniture wood edge milling machine

This automatic curved / straight line multi-function edge milling machine is a machine that specializes in processing straight lines and curved special-shaped wood. It is mainly suitable for solid wood furniture manufacturers. For example: wardrobe / solid wood furniture, etc. and the processing of various wood bending wood Making solid wood door frames, solid wood cabinets, wood panel splicing, wood milling, wood slotting, etc., is a rare machine in solid wood furniture and wood processing.

Product Paramenters

|

Model

|

WX2500

|

|

Power

|

5.5kw

|

|

Max.working length

|

2500mm

|

|

Max.working width

|

adjustable

|

|

Max.working thickness

|

100mm

|

|

Max. processing height (curve)

|

110mm

|

|

Max. processing arc (curve)

|

120mm

|

|

Working desk size

|

2500*320mm

|

|

Spindle speed

|

9000r/min

|

|

Spindle diameter

|

35/40mm

|

|

Cutter external diameter

|

90-130mm

|

|

Dimension

|

3300*1300*1100mm

|

|

Weight

|

1150kg

|

How to operate:

After the milling cutter of the linear trimming machine is pressed into the work object, the milling can be pushed. The driving speed will vary depending on the type of wood, the depth of milling, and the sharpness of the cutter. If there is a feeling of being unable to push, or the motor sound is heavy, you need to slow down. During the advancement of the multi function linear trimming machine, the trimming machine should be kept stable and cannot be inclined, otherwise the milling will not be vertical.

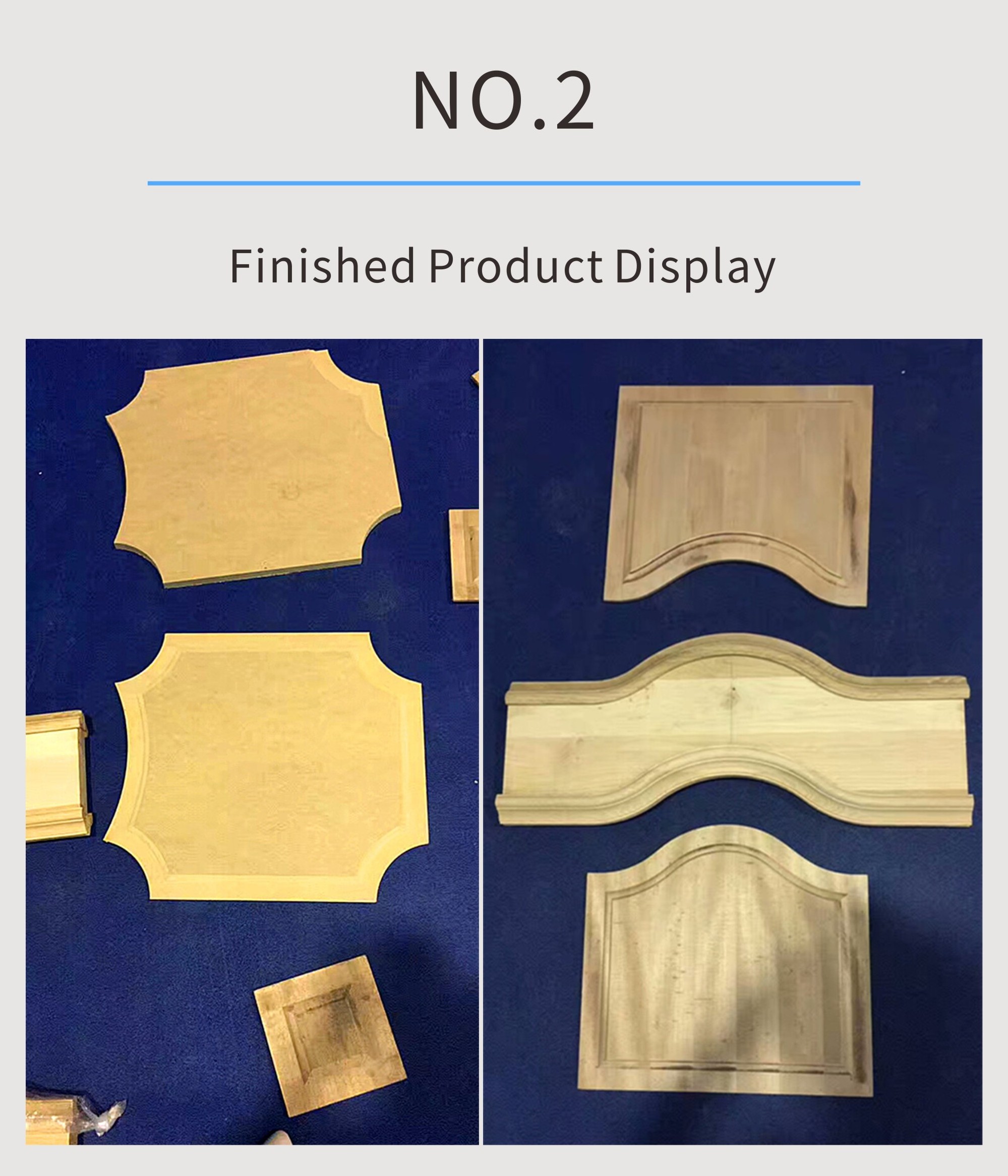

Details Images

1. After processing by this machine, the straightness of the sheet is better.

2. The machine can process multiple pieces at a time (stack of 2 pieces)

3. The manual operation of the machine is safe, and the hand is not close to the cutter.

4. This machine does not need technical workers, only need to load and unload, saving costs.

5. The advantage of this machine for processing long materials is more obvious, and the effect after splicing is good.

2. The machine can process multiple pieces at a time (stack of 2 pieces)

3. The manual operation of the machine is safe, and the hand is not close to the cutter.

4. This machine does not need technical workers, only need to load and unload, saving costs.

5. The advantage of this machine for processing long materials is more obvious, and the effect after splicing is good.

Packing&Delivery

Packing:

This

machine

is packed in standard export wooden cases. We will wrap the machine with plastic film to prevent scratches. Then use a wooden box to fix the fuselage to prevent the packing machine parts from being damaged due to bumps during transportation. Regarding packaging, we also support customization. If you have special requirements, please contact us for instructions.

Delivery:

Delivery:

About these

machine

, we have two ways to transport by sea and air. Please provide us with your address so that we can choose a more suitable transportation method for you. We can also deliver the

machine

to your agent in China if you have.

Certifications

We have been engaged in the wood machinery industry for many years and have accumulated rich experience in products and services. We always serve our customers with sincere attitude and professional knowledge, and provide customers with better products and better service. It is our persistent attitude.

Production Process

Our services

1. The warranty period of our

machine

is 1 year. During the warranty period, the machine parts are damaged by non-human factors, we will provide new parts for replacement free of charge (except the wearing parts).

2. We provide one-to-one online service throughout the day. If you have any questions about the machine , please feel free to contact us. We will provide professional answers for you.

3. In the same competitive conditions, we sincerely offer you the most favorable price without reducing product performance or replacing parts.

4. If you have time, we sincerely welcome you to visit our factory for further understanding and testing of product performance.

Thank you for your precious time! For more information about this machine , please feel free to send me inquiry and contact me!

2. We provide one-to-one online service throughout the day. If you have any questions about the machine , please feel free to contact us. We will provide professional answers for you.

3. In the same competitive conditions, we sincerely offer you the most favorable price without reducing product performance or replacing parts.

4. If you have time, we sincerely welcome you to visit our factory for further understanding and testing of product performance.

Thank you for your precious time! For more information about this machine , please feel free to send me inquiry and contact me!

Hot Searches