- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1~40mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

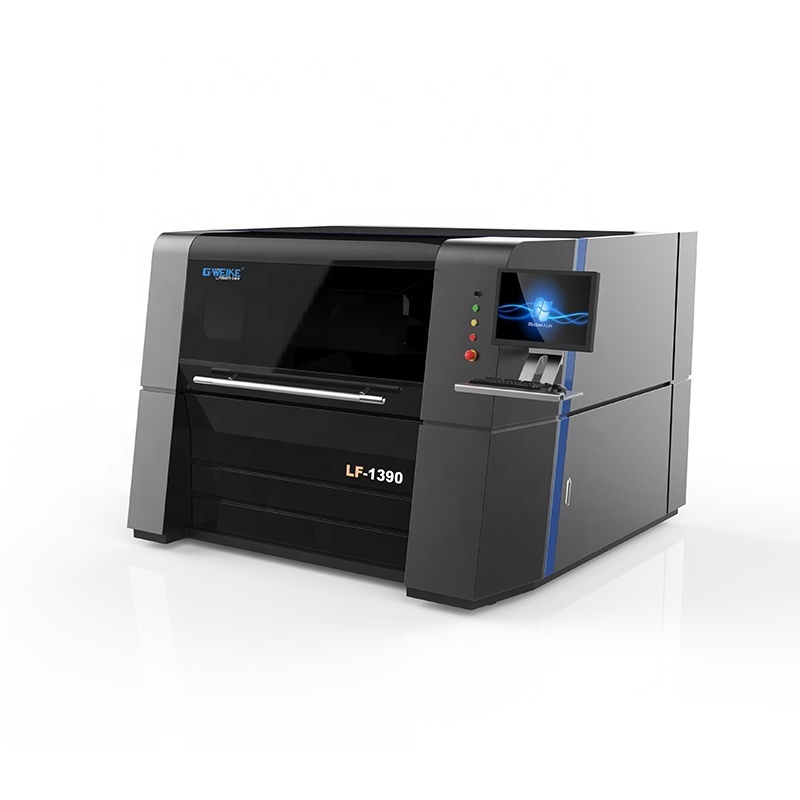

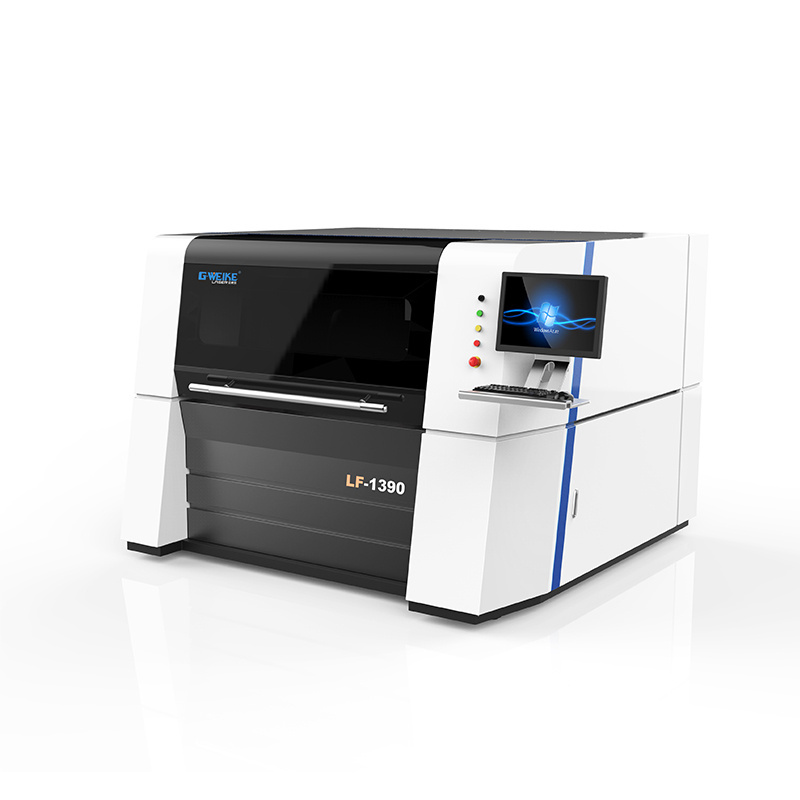

Brand Name:

-

Gweike

-

Weight (KG):

-

1950 KG

-

Core Components:

-

laser source

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Laser power:

-

500W / 700W / 1000W

-

Working area:

-

1300* 900mm

-

Cutting head:

-

Raytools Brand Cutting Head

-

Color:

-

Black-white

-

Reducer:

-

French MOTOVARIO Reducer

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

40m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Thickness:

-

1~40mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Gweike

-

Weight (KG):

-

1950 KG

-

Core Components:

-

laser source

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Laser power:

-

500W / 700W / 1000W

-

Working area:

-

1300* 900mm

-

Cutting head:

-

Raytools Brand Cutting Head

-

Color:

-

Black-white

-

Reducer:

-

French MOTOVARIO Reducer

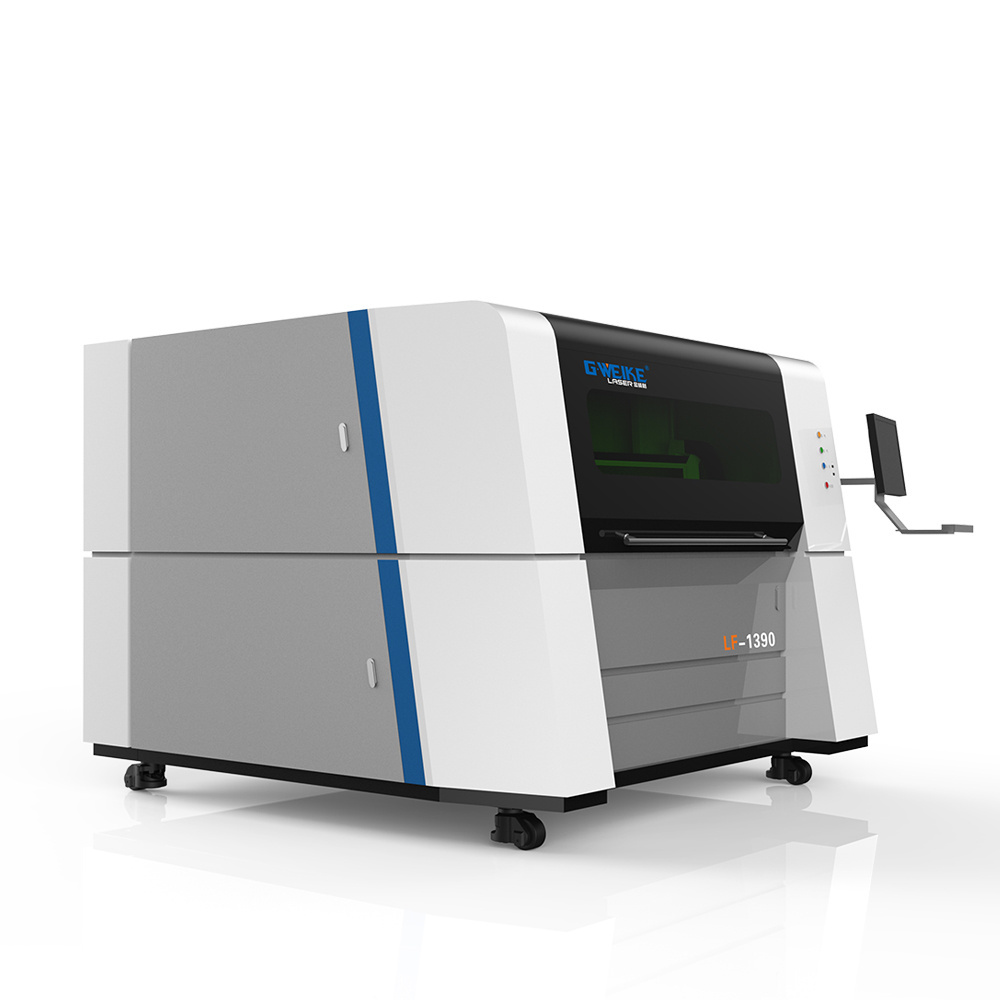

1300*900MM MINI SINGLE TABLE ENCLOSED STAINLESS STEEL ALUMINUM FIBER LASER CUTTING MACHINE WITH FACTORY PRICE

Specification

|

Application

|

LASER CUTTING

|

|

Applicable Material

|

Stainless Steel:0-10mm, Carbon Steel:0-20mm

Aluminum:0-10mm, Copper:0-8mm, Etc.

|

|

Positioning Accuracy

|

0.03mm

|

|

Repositioning Accuracy

|

0.02mm

|

|

X/Y axis moving speed

|

40m/min

|

|

Graphic Format Supported

|

AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

|

|

Machine Dimension

|

2100*2700*1650mm

|

|

Cooling Mode

|

WATER COOLING

|

|

Control Software

|

Cypcut

|

|

Brand Name

|

Gweike

|

|

Laser Source Brand

|

IPG/Raycus

|

|

Laser Head Brand

|

Raytools

|

|

Servo Motor Brand

|

Yaskawa

|

|

Guiderail Brand

|

HIWIN

|

|

Control System Brand

|

Cypcut

|

|

Working Platform Load

|

250KG

|

|

Weight (KG)

|

1500KG

|

|

Max Acceleration Speed

|

0.5G

|

|

Warranty

|

3 years

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts, Field maintenance and repair service

|

|

Applicable Industries

|

LF1390 fiber laser cutting machine as one classic model, widely used in many common areas of our life, such as processing of

stainless steel kitchenware, storage cabinet and other cabinets, is closely related to people's daily life. Used for cutting a variety of metal plates, mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, various alloy plate, rare metal and other metal materials.

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Laser power

|

1000W / 1500W / 2000W / 3000W

|

|

Working area

|

1300*900mm

|

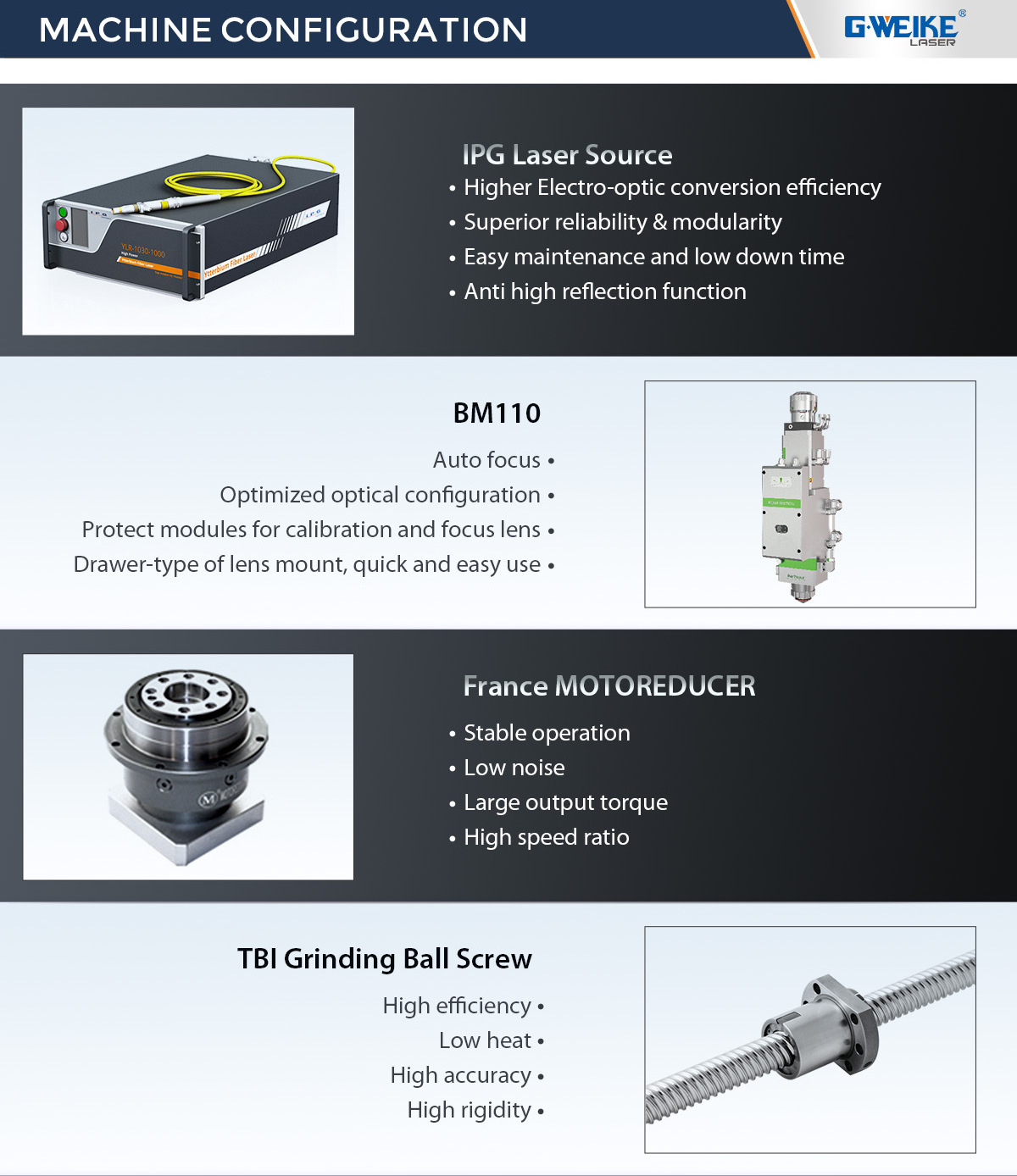

Machine configuration

Advantages:

1. Low cost and the power consumption is 0.5-1.5kw/h; Customer can cut all kinds of metal sheets by blowing air;

2. High-performance. Imported the original packaged fiber laser, with stable performance and the lifespan is over 100,000 hours;

3. High speed and efficiency, the speed of cutting metal sheets close to tens of meters;

4. The laser maintenance free;

5. The cutting edge looks perfect and the appearance is smooth and beautiful;

6. Imported the transmission mechanism and servo motor, and high cutting accuracy;

7. Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation

1. Low cost and the power consumption is 0.5-1.5kw/h; Customer can cut all kinds of metal sheets by blowing air;

2. High-performance. Imported the original packaged fiber laser, with stable performance and the lifespan is over 100,000 hours;

3. High speed and efficiency, the speed of cutting metal sheets close to tens of meters;

4. The laser maintenance free;

5. The cutting edge looks perfect and the appearance is smooth and beautiful;

6. Imported the transmission mechanism and servo motor, and high cutting accuracy;

7. Dedicated software enables graphic or text to be instantly designed or processed. Flexible and easy operation

Sample display

Fiber Laser Cutting Machine application

1. Mechanical structure on the reverse side, multi-functional cutting of metal sheets and pipes, easy to change the workbench, not

only can cut round and square pipes, but also cut holes in the forming box.

2. Lines and holes with different diameters can be cut from different directions.

3. You can cut the inclined part at the end of the pipe.

4. It can cut the branch pipe that intersects the main round pipe.

5. Square, waist and round holes can be cut in the pipe.

6. Various graphics can be cut on the surface of the square tube.

7. Can cut metal plates of different sizes.

8. Can cut holes in the forming box.

Professional fast cutting of various metal plates and pipes (plus pipe cutting device), mainly used for stainless steel, carbon

steel, galvanized plate, electrolytic plate, brass, aluminum, steel, various alloy plates, rare metals and other materials

only can cut round and square pipes, but also cut holes in the forming box.

2. Lines and holes with different diameters can be cut from different directions.

3. You can cut the inclined part at the end of the pipe.

4. It can cut the branch pipe that intersects the main round pipe.

5. Square, waist and round holes can be cut in the pipe.

6. Various graphics can be cut on the surface of the square tube.

7. Can cut metal plates of different sizes.

8. Can cut holes in the forming box.

Professional fast cutting of various metal plates and pipes (plus pipe cutting device), mainly used for stainless steel, carbon

steel, galvanized plate, electrolytic plate, brass, aluminum, steel, various alloy plates, rare metals and other materials

Hot Searches