- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HR

-

Voltage:

-

220/380v, 220v 380v

-

Dimension(L*W*H):

-

1.4*1.5*1.6m

-

Weight:

-

850 KG

-

Features:

-

Energy-saving

-

Raw Material:

-

coal powder and charcoal powder

-

Product name:

-

charcoal ball Press machine

-

Keyword:

-

Chacoal Briquette Making Machine

-

Type:

-

Electric

-

Capacity:

-

500 kg per hour

-

Certification:

-

ISO CE

-

Diameter of briquettes:

-

50~80mm Customized

-

Package:

-

Wooden Case

Quick Details

-

Marketing Type:

-

New Product 2022

-

Application:

-

barbecue fuel boiler cooking etc, BBQ heating cooking

-

Production Capacity:

-

500-800kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HR

-

Voltage:

-

220/380v, 220v 380v

-

Dimension(L*W*H):

-

1.4*1.5*1.6m

-

Weight:

-

850 KG

-

Features:

-

Energy-saving

-

Raw Material:

-

coal powder and charcoal powder

-

Product name:

-

charcoal ball Press machine

-

Keyword:

-

Chacoal Briquette Making Machine

-

Type:

-

Electric

-

Capacity:

-

500 kg per hour

-

Certification:

-

ISO CE

-

Diameter of briquettes:

-

50~80mm Customized

-

Package:

-

Wooden Case

Product Overview

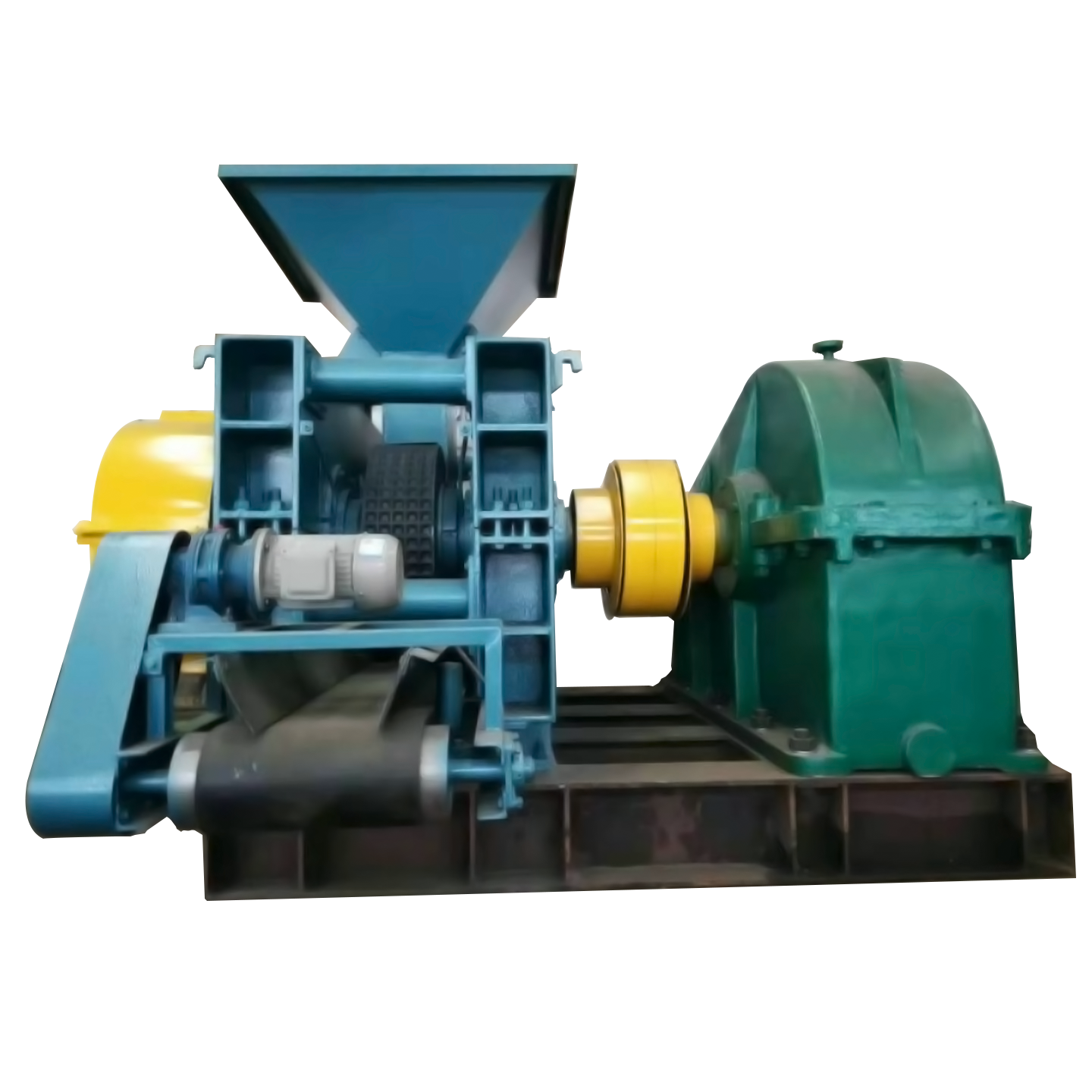

Charcoal ball press machine

charcoal ball press machine can be used to suppress, iron powder, coking coal, aluminum, iron, tin oxide, carbon powder, coal powder, slag, gypsum, tailings, sludge, kaolin, at the end of the activated carbon, coke and other powder, powder, waste, waste residue, is widely used in refractory material, power plants, metallurgical, chemical, energy, transportation, heating and other industries, after pressing ball mechanism for forming materials, energy conservation, environmental protection, It is easy to transport and improves the utilization rate of waste material, and has good economic and social benefits.

FEATURES AT A GLANCE

Charcoal ball pressing machine consists of three parts:

a feeding part;

Two transmission part;

Three forming part.

1, feeding part, mainly to achieve quantitative feeding to ensure that the material evenly into the roller.

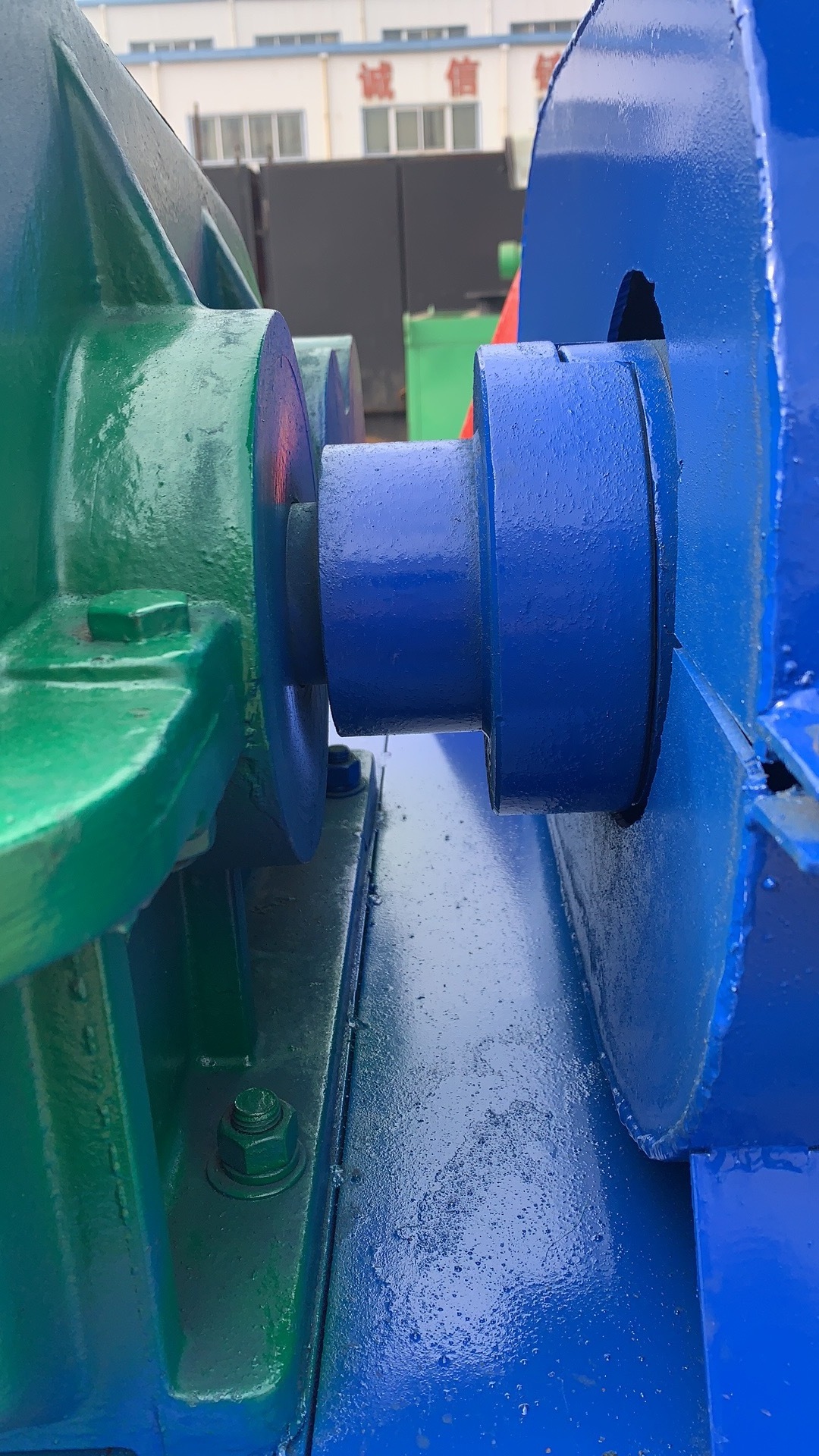

2, drive part, the main drive system is: motor -- triangle belt -- reducer -- open gear -- roller.

3, formin

g part, mainly refers to the host part, the core part is the roll.

round mould

coupling

feeding port

PRODUCT SPECIFICATIONS

|

The main technical parameters

|

|

|

|

|

||||

|

Model

|

HR290

|

|

|

|

||||

|

Dimension

|

1400*1500*1600mm

|

|

|

|

||||

|

Power

|

5.5kw

|

|

|

|

||||

|

Capacity

|

500-800kg/h

|

|

|

|

||||

|

Weight

|

800kg

|

|

|

|

||||

|

Roller

|

2 sets

|

|

|

|

||||

|

Reducer

|

1 set

|

|

|

|

||||

|

Mould

|

It can change to different form mould according to the customers requirement

|

|

|

|

||||

PRODUCT CONFIGURATION

different mould and final product

roller

round and pillow shape finished product

Installation and debugging of charcoal ball press machine:

The briquette ball press machine must have a relatively balanced base. Pay attention to correct the level and level the gap. The conveyor should also correspond to the height and level of the conveyor. After installation, strictly check whether the components are firmly connected. Whether there is any sundries on the machine, add enough lubricating oil in the reducer and gear box, and test the machine after confirming that the parts are correct. When testing the machine, check whether it is turned upside down. After running in the correct direction for 30 minutes, check whether the components have abnormal noise or heat. If the problem is found to be solved in time, prepare 300 kg of dry material (coal powder without moisture, fine sand or refractory). Material), dry grinding and polishing, about five times or so, then the formal production can be carried out. Please note: the moisture content has a great influence on the pressure and demoulding of the ball, it must be mastered, it is best to dry first and then wet.

Workshop product display

charcoal ball press machine waiting for transport

Wide application range of charcoal ball press machine

Product packaging

in wooden case

Shipping in containe

r

Certifications

Company Profile

Hot Searches