Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

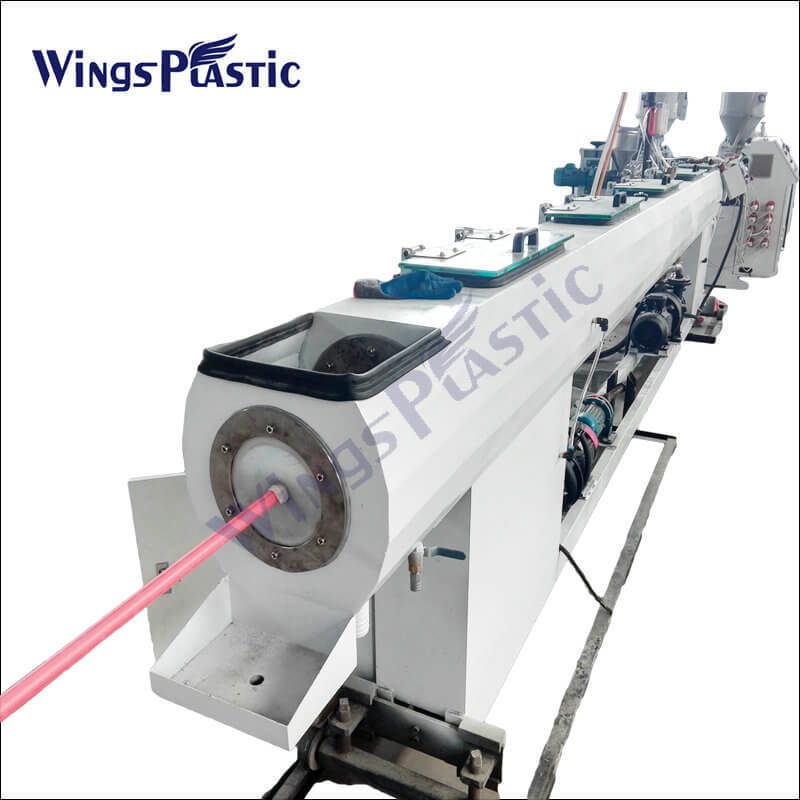

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

25000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

New Product 2020

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WingsPlastic

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

25000mm 2000mm 2500mm

-

Power (kW):

-

40

-

Weight:

-

3000 KG

-

Motor:

-

China Top Brand

-

Inverter:

-

Delta Brand

-

Temperature controller:

-

Omron Brand

-

Contactor:

-

Siemens Contactor

-

switch:

-

CHNT

-

After Warranty Service:

-

Video technical support

-

Marketing Type:

-

New Product 2020

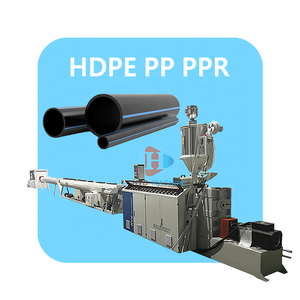

20-110mm Plastic PE HDPE PPR Pipe Making Production Machinery/ HDPE Tube Extruder Machine/ PE Pipe Extrusion Line

Product Description

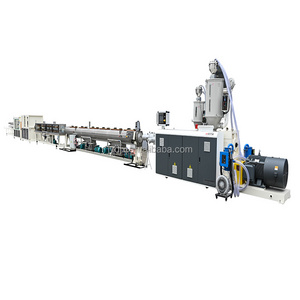

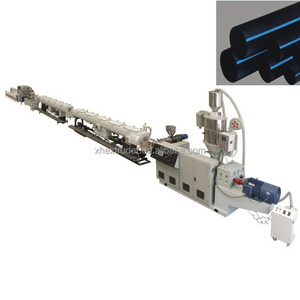

HDPE PE PP PPR Fully Automatic Plastic Pipe Extrusion Production Making Machine Line

Qingdao Wings Plastic Technology Co.,Ltd is a proffesional manufacturer for plastic extruder machinery production.

We could produce various pp pe pvc extruder machine, like plastic pipe extruder, pp meltblow fabric extruder, pp sheet / pp strap extruder etc.

PPR PE pipe production/extrusion line / PPR PE pipe making machinery is used to produce PPR pipes for cold and hot water supply in house. It's composed of vacuum feeding machine, hopper dryer, single screw extruder, mould, make line co-extruder, vacuum calibration and cooling tank, extended spraying cooling tank, haul off machine, printer, cutter and stack bracket.

Main advantages:

1. Barrier type screw, by which the material can get good plasticizing at low temperature but high extrusion output.

2. Barrel with feeding groove, material is 38CrMoAl and nitrogen treated, surface hardness is HRC 65-68, which can has a long use life.

3. Millipore type mould with suitable inner compression ratio which can guarantee to produce high quality PPR PE pipes.

4. High automatic level. The production line is controlled by PLC(touch screen). All parts, like extruder, haul off unit, cutter

etc can be controlled by touch screen synchronously.

PPR/PERT pipe production line

PPR pipe extrusion machine line

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul off machine → cutting machine → discharging rack

PPR pipe extrusion machine line

Raw material + additive → mixing → vacuum feeding machine → hopper dryer → single screw extruder → color code extruder → mould and calibrator → vacuum forming machine → cooling tank → haul off machine → cutting machine → discharging rack

Single Screw Extruder big capacity

There is 45/33,65/30,65/33,75/30,75/33 ... etc extruders according diameters and ouput.

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality pipe extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel>940, the surface of screw is chromeplated Feeding bush with water cooling system

High production capacity of extrusion on the high quality basis. Lower temperature plasticizing design, ensure high quality pipe extrusion. Material of screw and barrel: 38CrMoAlA, nitrogen quenched (0.4-0.7mm ), Rigidity of screw: >740 , Rigidity of barel>940, the surface of screw is chromeplated Feeding bush with water cooling system

Markline Extruder

Always PPR pipe, HDPE water pipe needs the markline extruder to produce a blue or red markline on pipe surface.

Pipe Extrusion Die head

The die head is made by 40Cr moulds materials.

Using mica heating way

Using mica heating way

Pipe Vacuum Tank

It is adopted stainless steel materials, high quality vacuum and water pumb. There is flow stabilization system for better pipe surface.

Water cooling tank

it is stainless steel materials.

It could be water leaching cooling way or water spray cooling way according pipe diameters and extrusion speed.

It could be water leaching cooling way or water spray cooling way according pipe diameters and extrusion speed.

Haul off unit

It could be rubber belt or rubber block clamping way.

2 claw, 3 claw, 4 claw ,6 claw, 8 claw, 12 claw made according pipe diameters.

2 claw, 3 claw, 4 claw ,6 claw, 8 claw, 12 claw made according pipe diameters.

Cutting Machine

Always it is no dust cutting way. The blades will cut the pipe by rotating way with pneumatic powder

Small Pipe Winding Unit

It could be double wheel or single wheel winding according pipe diameters. Always 10-40mm will use double wheel like the photo.

Bigger Pipe Winding Unit

It could be used for 16-63mm or 50-110mm diameters

Stacker

Length 6000mm

Stacking way:Pneumatic way

Stacking way:Pneumatic way

Model & Parameters

|

Model/Item

|

Pipe range

|

Extruder

|

Max.output

|

Motor power

|

Total power

|

|

PE-63

|

16-63mm

|

SJ65/33 SJ25/25

|

120-180kg/h

|

45kw

|

110kw

|

|

PE-110

|

16-110mm

|

SJ65/33 SJ25/25

|

150-200kg/h

|

55kw

|

130kw

|

|

PE-160

|

50-160mm

|

SJ75/33 SJ25/25

|

150-220kg/h

|

75kw

|

150kw

|

|

PE-250

|

75-250mm

|

SJ75/33 SJ25/25

|

180-250kg/h

|

90kw

|

280kw

|

|

PE-315

|

110-315mm

|

SJ90/33 SJ25/25

|

250-350kg/h

|

132kw

|

350kw

|

|

PE-450

|

160-450mm

|

SJ90/33 SJ25/25

|

350-450kg/h

|

160kw

|

400kw

|

|

PE-630

|

315-630mm

|

SJ120/33 SJ25/25

|

550-850kg/h

|

200kw

|

500kw

|

Final Product & Application

Company Introduction

Qingdao Wings Plastic Technology Co., LTD., specializing in the production of HDPE PP PVC PA single wall corrugated pipe machine, double-wall corrugated pipe production line, HDPE PP PVC Sheet, Coil Mat, Strap, Protector Machine

Equipment operation is stable, automatic production, saving labor, efficient extrusion

Equipment operation is stable, automatic production, saving labor, efficient extrusion

FAQ

1.Low cost

All the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality

We choose our material very strict.

All the material come to our factory must pass the quality test

Substandard goods are returned to the supplier.

3. Engineers available to serve oversea

Our engineer will provide the best service for customers

4.Quick delivery

The company provide just in time delivery with its streamlined supply chain.

5.Cost saving

Se take strong attention to every detail in the manufacturing process.

The quality control in our factory is very strict.

All defective semi-manufactures must be treated again or reject.

All the machine must be checked out ,then delivered to our customer.

All about that pushing up the price,but get good quality machine.

What we want to do is give our customer a good quality product with stable working and long lived.

All the machine ,we make it ourself to reduce the cost of our customer.

2.Genuine product with excellent quality

We choose our material very strict.

All the material come to our factory must pass the quality test

Substandard goods are returned to the supplier.

3. Engineers available to serve oversea

Our engineer will provide the best service for customers

4.Quick delivery

The company provide just in time delivery with its streamlined supply chain.

5.Cost saving

Se take strong attention to every detail in the manufacturing process.

The quality control in our factory is very strict.

All defective semi-manufactures must be treated again or reject.

All the machine must be checked out ,then delivered to our customer.

All about that pushing up the price,but get good quality machine.

What we want to do is give our customer a good quality product with stable working and long lived.

Recommend Products

Contact Us

Hot Searches