Name: Frame

Brand: SHUGUANG

Original: China

Raymond mill is widely used for nonflammable and nonexplosive materials with Moh's hardness below grade 9.3,moisture content of less than 6%, such as,quartz,recrystal,calcite,potashfeldspar,talc,marble,limestone,dolomite,fluorite,lime,activated clay,activated carbon,bentonite,kaolin,cement,phosphate ore,gypsum,graphite,glass,manganese ore,titanium ore,copper ore,chrome ore,refractory materials,thermal insulation materials,coal coke,coal powder,carbon black,pottery clay,titanium dioxide,ferric oxide. Generally, final size is between 60 mesh and 325 mesh(0.044mm-0.125mm), some parts can be 1000 mesh(0.013mm).

Raymond Mill's working principle is that the grinding roller is rolled tightly on the grinding ring under the action of centrifugal force. The shovel scoops the material to the middle of the grinding roller and the grinding ring. The material is broken into powder under the action of the grinding pressure, and then Under the action of the fan, the powdered material is blown through the analyzer, and the fineness-required material passes through the analyzer. The regrind chamber can no longer meet the required requirements and continue to be ground. The material of the analyzer enters the cyclone separator and is collected and collected. The exhaust uses industrial filter cloth to separate exhaust air into powder.

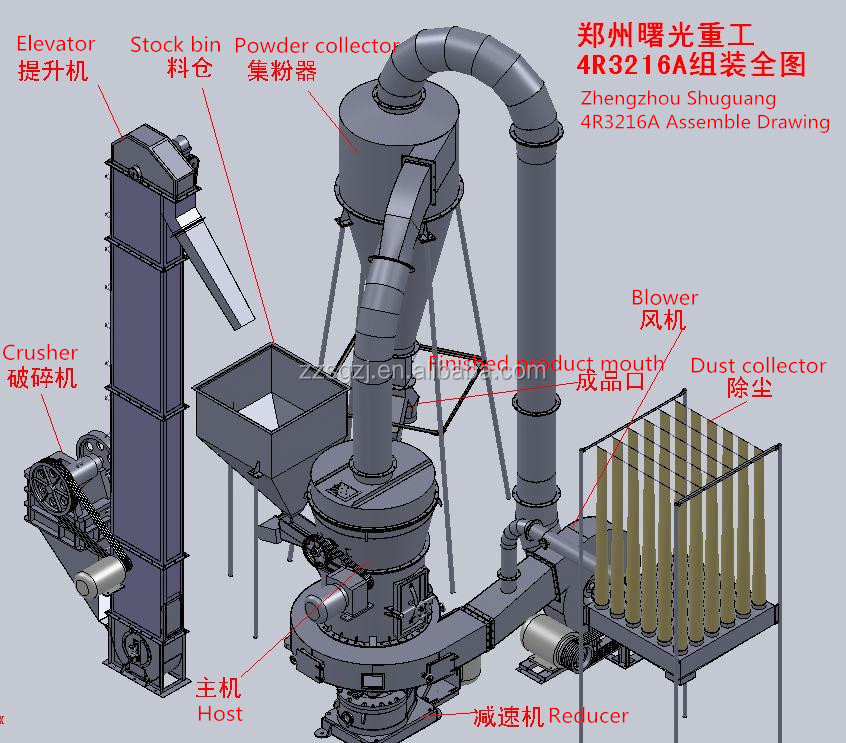

Raymond Mill's complete structure is composed of main engine, analyzer (pulverizer), pipeline device, blower, finished cyclone separator, jaw crusher, bucket elevator, electromagnetic vibrating feeder, electronically controlled motor and other components. Raymond Mill's main machine consists of a frame, air inlet volute, blade,grinding roller, agrinding ring, cover and motor.

1. Raymond Mill's three-dimensional structure, small footprint, complete sets, from the block material to the finished powder independently into a production system.

2. The fineness of the finished powder is even and the screening rate is 99%. This is difficult for other milling equipment.

3. The main drive of the milling machine adopts a sealed gear box and pulleys, with stable transmission and reliable operation.

4. The important parts of Raymond Mill are made of high-quality steel. Wear-resistant parts are made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

5, the electrical system adopts centralized control, the milling workshop can basically realize unmanned operation, and convenient maintenance.

Name: Frame

Brand: SHUGUANG

Original: China

Name:

Grinding Roller

Brand:

SHUGUANG

Original:

China

Grinding rollers to grind the material

Name:

Grinding Ring

Brand:

SHUGUANG

Original:

China

Name:

Blade

Brand:

SHUGUANG

Original:

China

The shovel scoops the material to the middle of the grinding roller and the grinding ring

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Packaging

|

|

|

|

Size

|

1*20ft

|

|

|

Weight

|

5 T

|

|

|

Packaging Details

|

This is a high-pressure Raymond mill for Madagascar, model 3R2615. This is a complete set of production lines, so it is equipped with a 20-foot cabinet.

|

|

|

Packaging

|

|

|

|

Size

|

LCL

|

|

|

Weight

|

3T

|

|

|

Packaging Details

|

This is the Raymond mill sent to foreign countries, the model is 3R2115. This is just a device that Raymond mills, so it is a consolidation. Shipped to Urumqi and sent abroad.

|

|

Zhengzhou Shuguang Heavy Machinery Co.Ltd id founded in 1993, which is a specialized enterprise dedicated to R & D and production of the raymond mill, calcium powder machine, all kinds of crushing machines, and mixer. our company by eputation first, service first, customer first is an objective and take integrity as life.All for customer's satisfaction efforts, all for the company's long term healthy development efforts. We solemnly promise that we will depelope us with good quality and credible after sale service! We sincerely welcome you to our company and give us suggestions and directions!!!

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year.

Q: How long is the warranty of your equipment? Do you supply spare parts?

A: Our warranty period is one year generally. We can supply spare parts.

Q: Do you provide after-sale service?

A: Yes. We have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 10-15 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide free design solution?

A: Yes, we could offer design solution for free.

If you are looking for this machine,please contact us now!