- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

MoLa

-

apperance:

-

polished surface

-

material:

-

mo alloy

-

purity:

-

99.95%

-

density:

-

10.2g/cm3

-

technique:

-

forged,lathed or ground

-

application:

-

in vacuum and high temperature condition

-

condition:

-

annealed

-

Product name:

-

molybdenum alloy rod

Quick Details

-

Dimensions:

-

Customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TJ Mola rod

-

Model Number:

-

MoLa

-

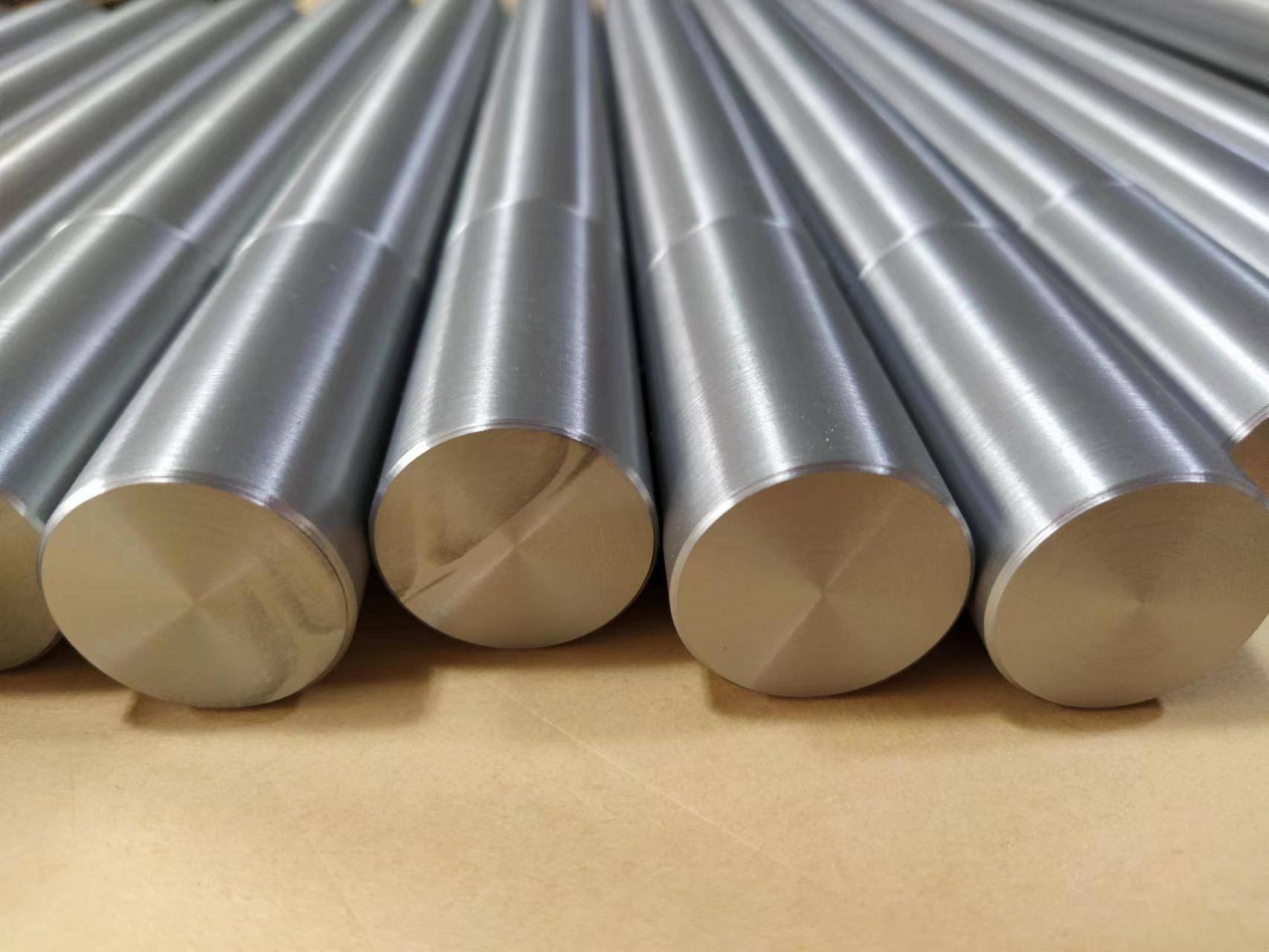

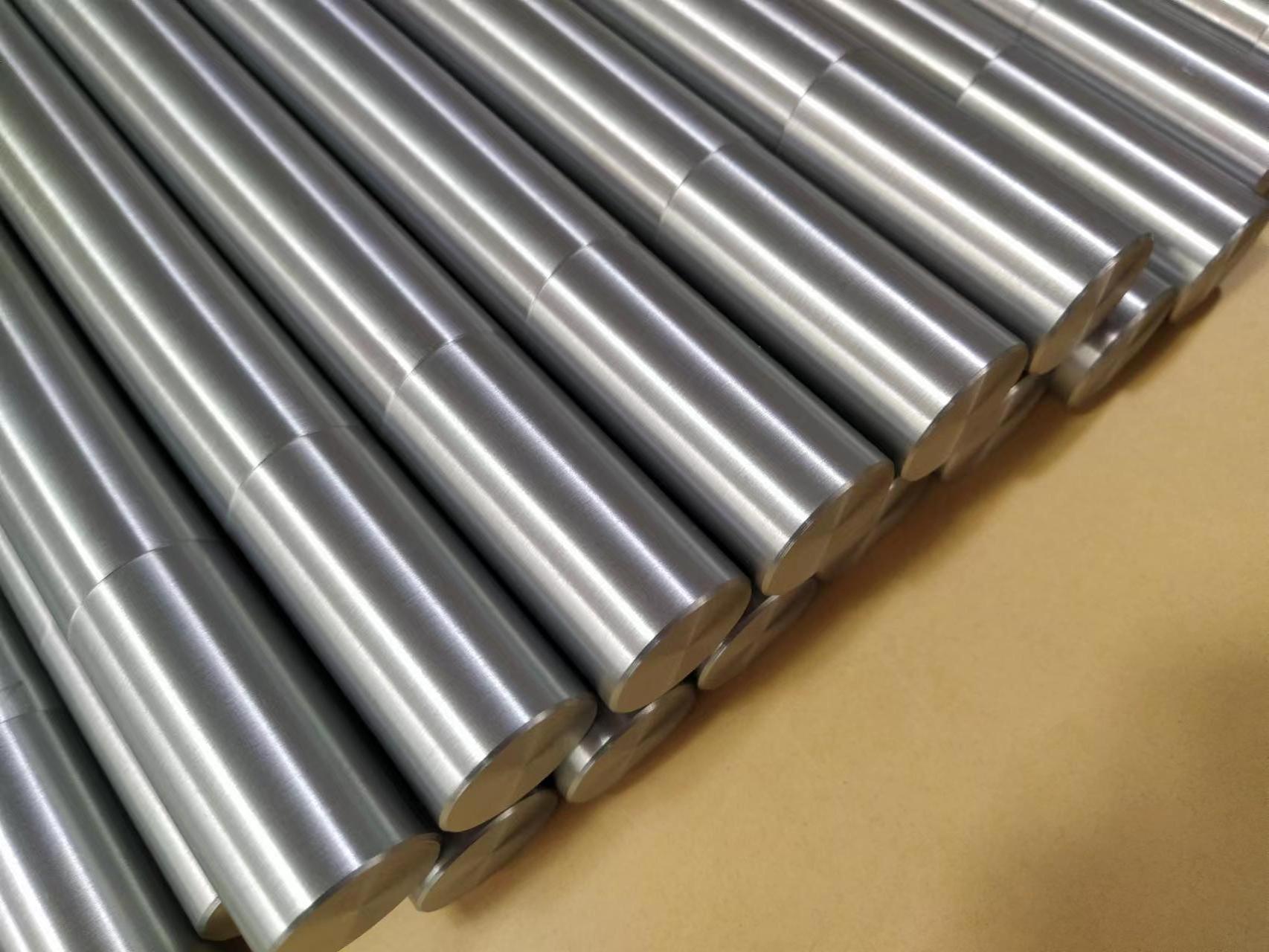

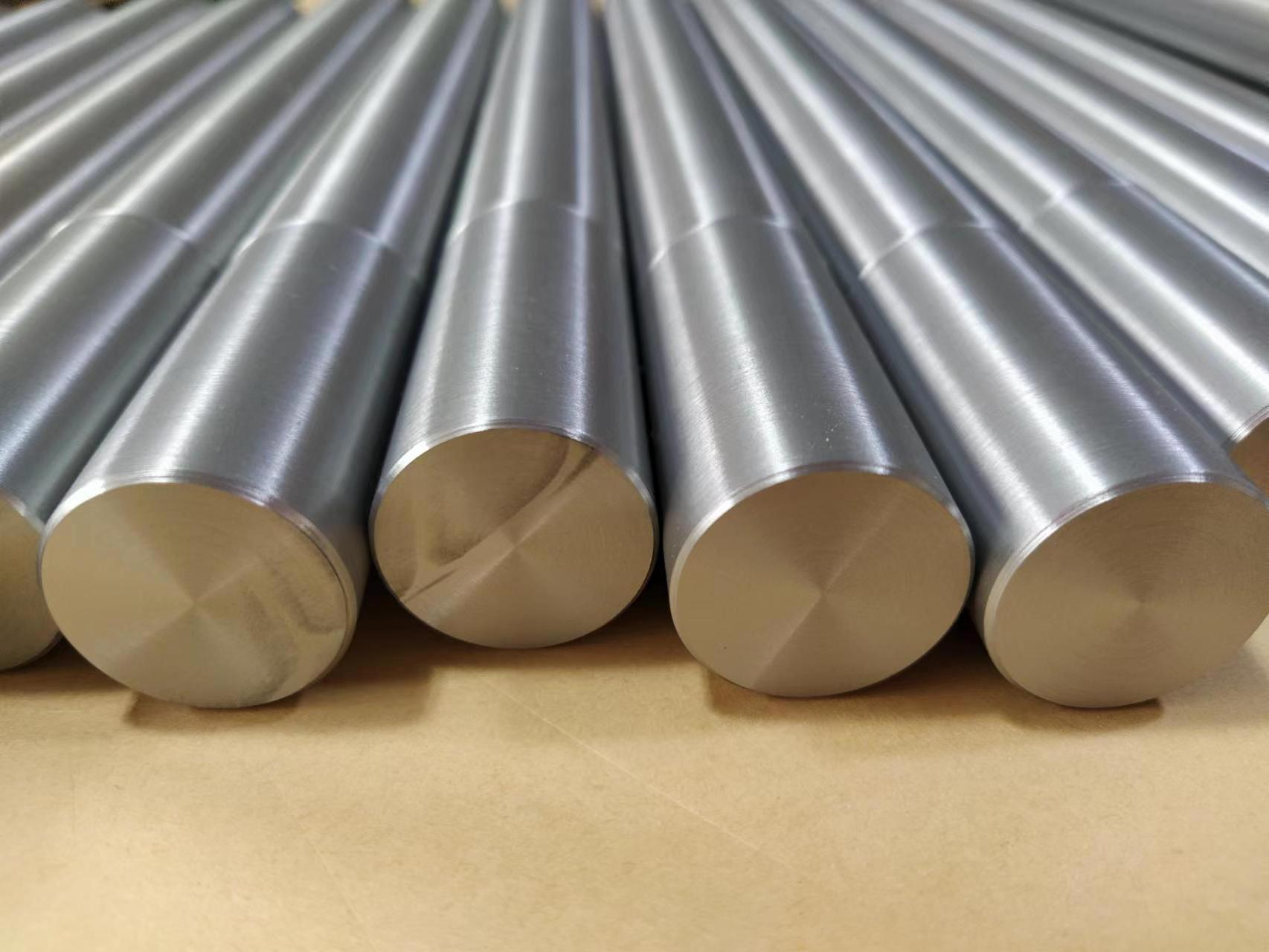

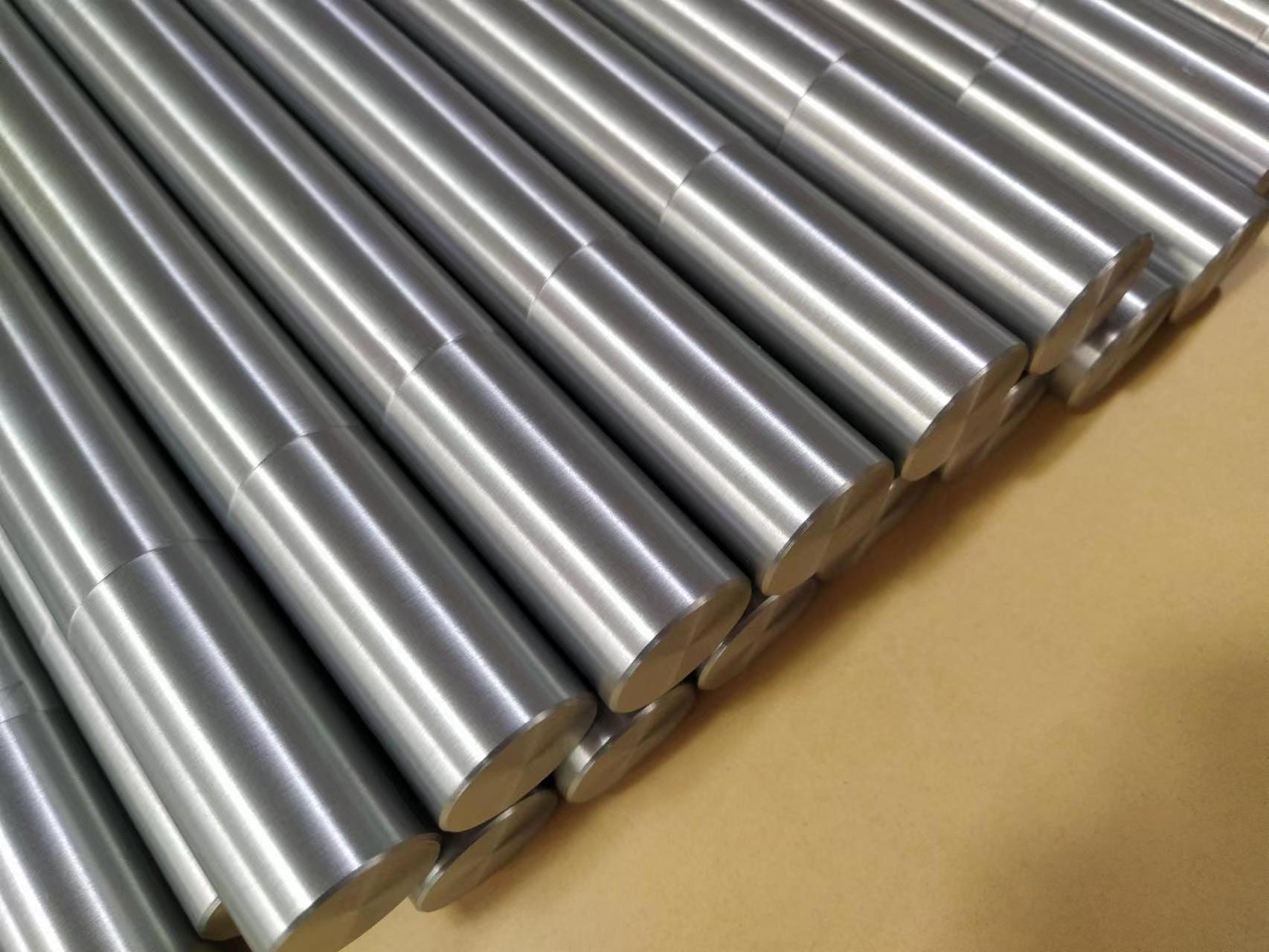

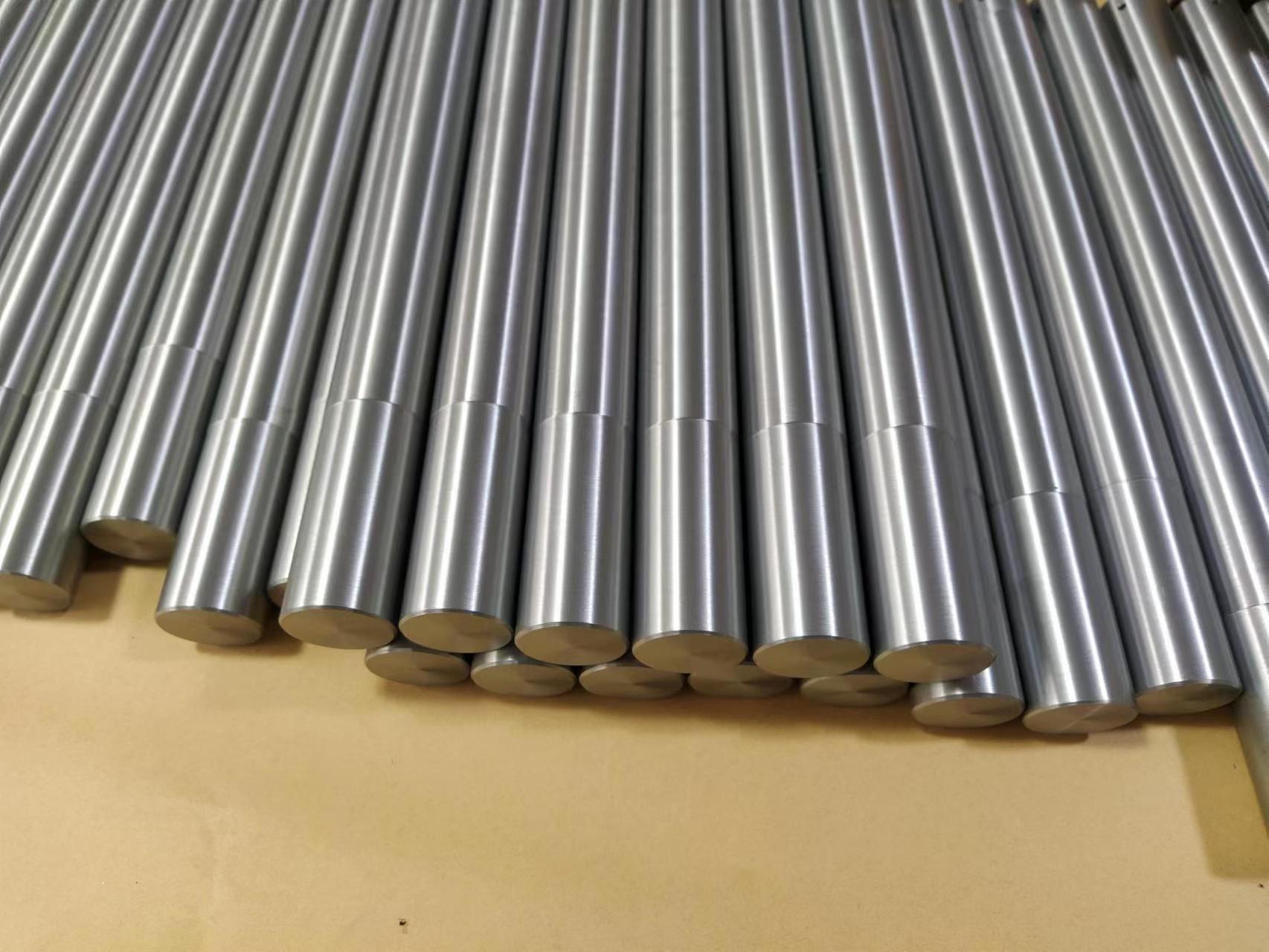

apperance:

-

polished surface

-

material:

-

mo alloy

-

purity:

-

99.95%

-

density:

-

10.2g/cm3

-

technique:

-

forged,lathed or ground

-

application:

-

in vacuum and high temperature condition

-

condition:

-

annealed

-

Product name:

-

molybdenum alloy rod

Description:

Mo-la roads are widely applied for heating elements in high-temperature furnaces, electrodes, screws, rabbles in rare earth smelting industry, heating electrodes in glass industry and support of lamp in the lighting industry, etc.

Specification:

1.We produce pure and lanthanide doped molybdenum alloy rod;

2. After being mixed with lanthanum, pure molybdenum grain is free from dislocation movement. As a result, the process of recrystalization is prolonged and the temperature can be increased more than 600 centigrade. Mo-la rods can serve longer with better performance.

3. Mo-la rod is manufactured in random length pieces or cut to customers' desired lengths with diameters ranging from 0.20 inches to 4 inches.

4. Mo-la rod has good properties of high strength, uniform internal organization and excellent resistance to high temperature creep;

5.The key technology of the production of Mo-la rods lies in the purity of molybdenum, quantity of lanthanum and mixing ways.

6. Our Mo-la rod is approved by ASTM B 386-2003 and GB 3876-2007 and GB 3877-2006.