- Product Details

- {{item.text}}

Quick Details

-

Application:

-

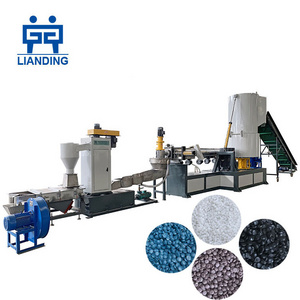

Granules Production

-

Raw material:

-

PP/PE film or regrind flakes

-

Function:

-

Pellets/granules

-

Machine name:

-

Plastic granulator

-

Electric parts:

-

Siemens/Schneider/RKC

-

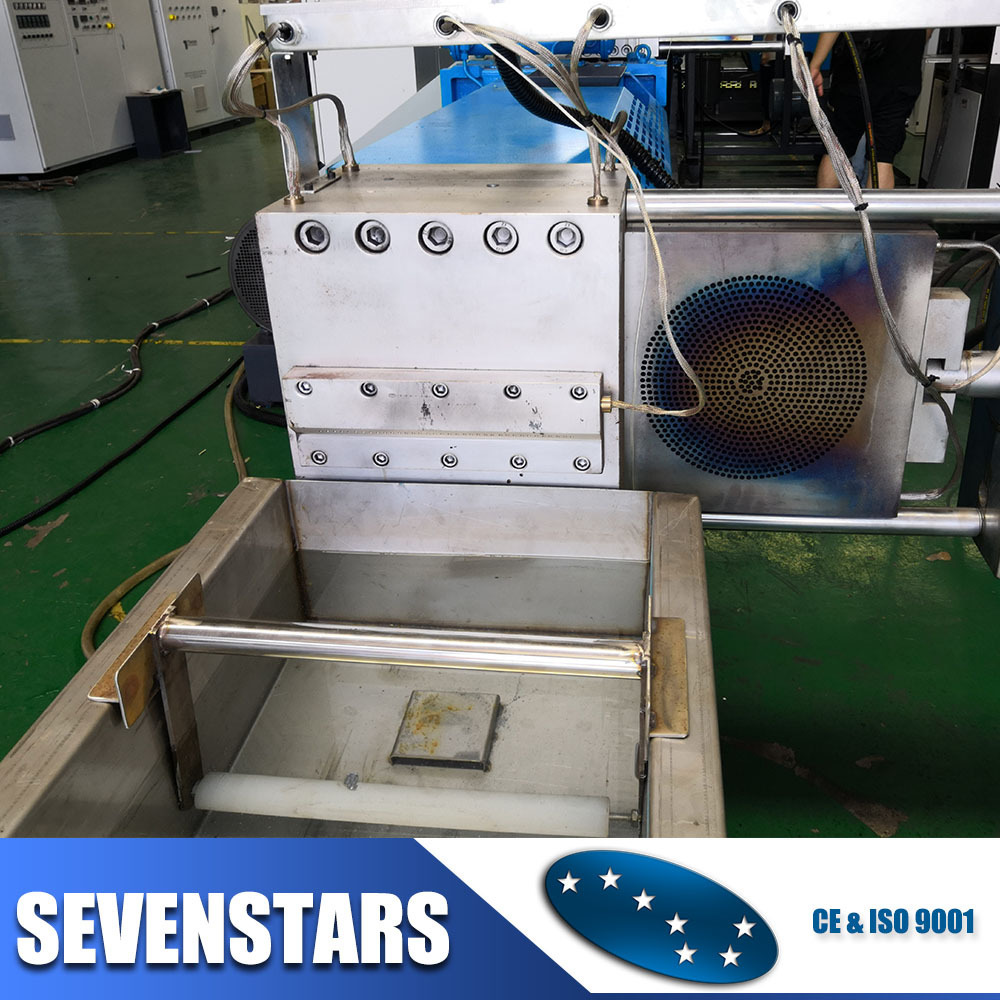

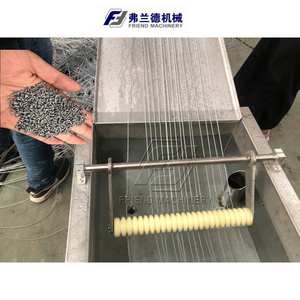

Cutting ways:

-

Water ring / noodle cutting

-

Machine Type:

-

Single/double Stage Pelletizing

-

Name:

-

plastic pelletizing machine

-

Keywords:

-

pp/pe plastic granulator extrusion line

-

Max. Capacity:

-

100-1000kg/h

-

Certification:

-

CE ISO

-

Power:

-

37-132 Kw

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Material:

-

PP/PE

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Online support, Video technical support, Engineers available to service machinery overseas

-

Application:

-

Granules Production

-

Raw material:

-

PP/PE film or regrind flakes

-

Function:

-

Pellets/granules

-

Machine name:

-

Plastic granulator

-

Electric parts:

-

Siemens/Schneider/RKC

-

Cutting ways:

-

Water ring / noodle cutting

-

Machine Type:

-

Single/double Stage Pelletizing

-

Name:

-

plastic pelletizing machine

-

Keywords:

-

pp/pe plastic granulator extrusion line

-

Max. Capacity:

-

100-1000kg/h

-

Certification:

-

CE ISO

-

Power:

-

37-132 Kw

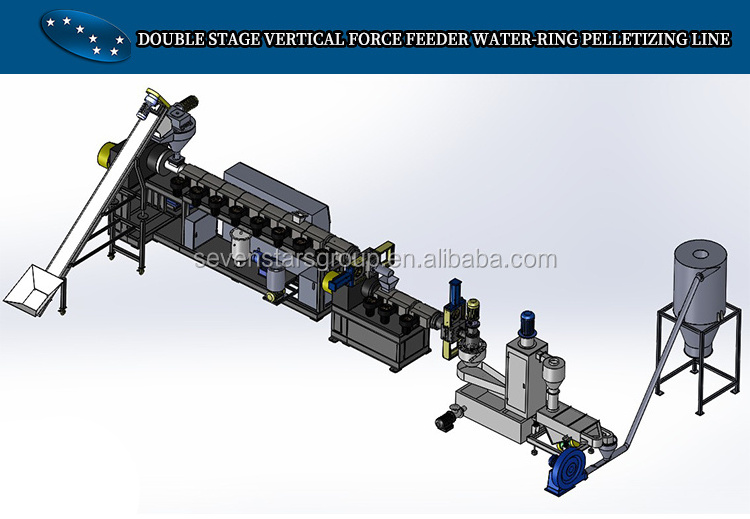

SJ series film recycling pelletizer production line is special equipment or the film recycling and pelletizing. With compacting machine, it could pre-compact the thin material into the small granule, making the automatic feeding material easier, and it efficiency improves the production. Cylinder type hydraulic changer with vacuum gas exhausting enables the non-stop changiing filter and no leaking material. Pelletizing by Die-Face-Cut improves the pelletizing quality.

| Model |

Screw diameter (mm) |

Rotary Speed (rpm) |

Main motor (Kw) |

Compacting machine (Kw) | Out put (Kg/h) |

|

SJ85-33 |

85 |

10-120 |

55 |

37 |

150-180 |

|

SJ100-33 |

100 |

10-120 |

90 |

55 |

250-300 |

|

SJ130-33 |

130 |

10-120 |

132 |

75 |

300-400 |

|

SJ160-33 |

160 |

10-120 |

160 |

90 |

500-600 |

|

SJ180-33 |

180 |

10-120 |

250 |

132 |

800-1000 |