- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110V/220V/380V

-

Power:

-

126.8KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

/

-

Product name:

-

maize flour making machine

-

Final products:

-

wheat white maize meal,special maize meal

-

Control:

-

PLC touch screen

-

Pipe:

-

Stainless steel

-

Capacity:

-

50 ton per day

-

Application:

-

Food Flour Grinding Mill Machine

-

Raw material:

-

Maize Corn

-

Color:

-

Customer Demand

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SIDA

-

Production Capacity:

-

50ton/day

-

Voltage:

-

110V/220V/380V

-

Power:

-

126.8KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

/

-

Product name:

-

maize flour making machine

-

Final products:

-

wheat white maize meal,special maize meal

-

Control:

-

PLC touch screen

-

Pipe:

-

Stainless steel

-

Capacity:

-

50 ton per day

-

Application:

-

Food Flour Grinding Mill Machine

-

Raw material:

-

Maize Corn

-

Color:

-

Customer Demand

-

Certification:

-

CE

Products Description

Product Paramenters

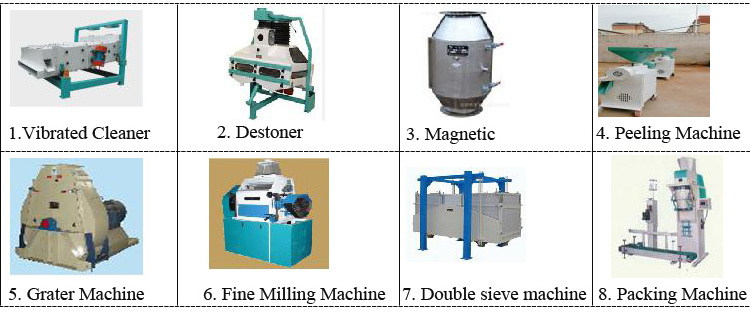

Main components of

maize flour making machine

|

Product

|

Quantity

|

Unit Power(kw)

|

Total Power

|

|

Combined vibrate cleaner & destoner

|

1

|

0.25*2

|

0.5

|

|

Magnetic selector

|

4

|

|

|

|

Polisher

|

2

|

15

|

30

|

|

Pulverizer

|

1

|

75

|

75

|

|

Single warehouse screen

|

1

|

1.1

|

1.1

|

|

Unloader

|

2

|

/

|

/

|

|

Packing counter

|

3

|

/

|

/

|

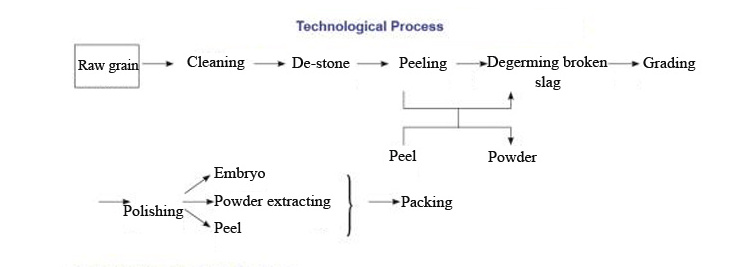

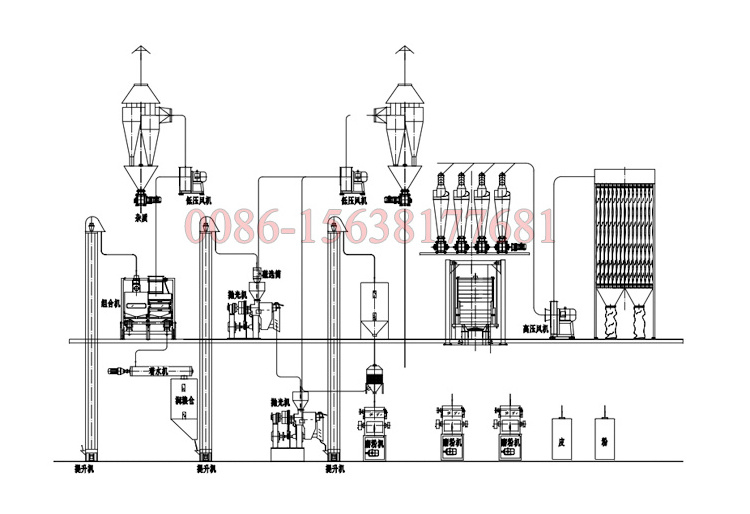

Processing flow

The maize mainly have three parts: germ, bran and Endosperm.

Endosperm is mainly for get fine maize product, like maize flour, maize grits maize rice and so on.

Germ and peel are mainly by-products with for animal feeding

From maize to fine products, it need though cleaning system to clean maize well and degermintor remove all germ and peel from maize, to get cleaned and well Endosperm to prepare produce good quality maize final products. then the endosperm go to milling section to mill it in to flour /meal /grits/ rice depend on designing.

Endosperm is mainly for get fine maize product, like maize flour, maize grits maize rice and so on.

Germ and peel are mainly by-products with for animal feeding

From maize to fine products, it need though cleaning system to clean maize well and degermintor remove all germ and peel from maize, to get cleaned and well Endosperm to prepare produce good quality maize final products. then the endosperm go to milling section to mill it in to flour /meal /grits/ rice depend on designing.

Flow chart:

Input maize --maize cleaner and destoner--maize moisture dampener --degerminator--roller mill--plansifter-

super maize meal/special maize meal/maize grits--packing

super maize meal/special maize meal/maize grits--packing

Description:

1. Cleaning part:

To clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, maize was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening. This section is make the maize/corn to prepare for milling part and to protect the machinery as well.

2. Milling part:

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: mill the wheat to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to ensure flour quality.

3. Packing part:

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. PLC controlling system:

To control the whole set of machinery to work well and showing the process of working

To clean out the middle and small impurity from wheat. e.g., dust, stone, magnetic material, maize was bitten by insect and so on.Includes beating, screening, destoner, magnetic separator and dampening. This section is make the maize/corn to prepare for milling part and to protect the machinery as well.

2. Milling part:

Include different number of mill and sifter to mill the wheat and separate the flour and bran

(1) Mill: mill the wheat to break the integrity by the roller moving

(2) Sifter: to separate the flour and bran, also separate large size and small size to ensure flour quality.

3. Packing part:

The packing part can be manual one also can be auto one, this can be designed according to requirement and machine capacity.

4. PLC controlling system:

To control the whole set of machinery to work well and showing the process of working

Customer feedback

Packaging & Shipping

Contact us

Contact name: Rita Wang

Email: sales@sidamachine.com

What’s app: 86 15378709361

Hot Searches