- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

486 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yuxiang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

7.5 kW

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

liquid soap homogenizer mixer

-

experience:

-

over 10 years

-

appliance:

-

shampoo detergent shower gel

-

warranty:

-

1 year

-

place of origin:

-

Jiangsu, China

-

material:

-

stainless steel

-

capacity:

-

customized

-

Function:

-

mixing homogenizing

-

quality:

-

CE certificate

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

GMP

Quick Details

-

Barrel Volume (L):

-

500 L

-

Max. Loading Volume (L):

-

500 L

-

Range of Spindle Speed(r.p.m):

-

1 - 65 r.p.m

-

Max. Loading Capacity:

-

5000L

-

Weight (KG):

-

486 KG

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yuxiang

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Referring

-

Power (kW):

-

7.5 kW

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

liquid soap homogenizer mixer

-

experience:

-

over 10 years

-

appliance:

-

shampoo detergent shower gel

-

warranty:

-

1 year

-

place of origin:

-

Jiangsu, China

-

material:

-

stainless steel

-

capacity:

-

customized

-

Function:

-

mixing homogenizing

-

quality:

-

CE certificate

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Certification:

-

GMP

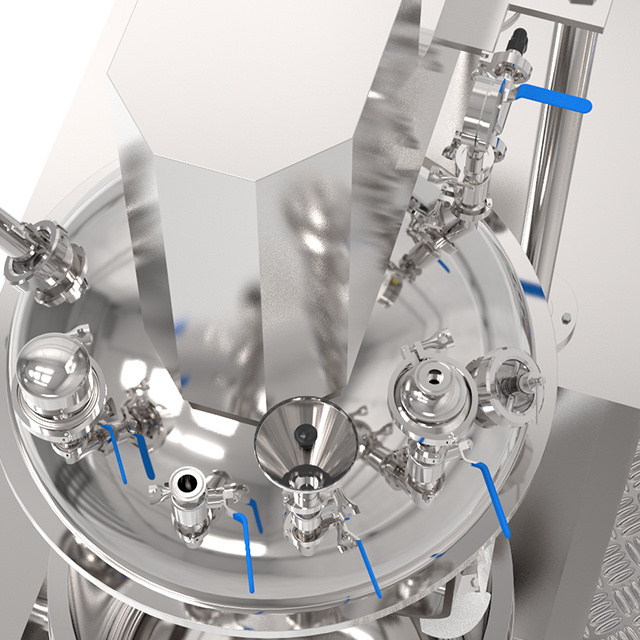

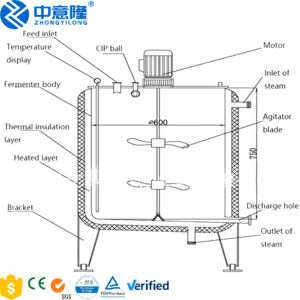

Hand wash liquid soap making machine stirrer mixing tank cosmetic cream making machine

1, High speed disperser m ight mixing and disperse viscously, solid and liquid etc. It ’ s used for produce liquid washing products like shampoo, dish washing, hand washing, lotion, liquid soap, detergent, gel etc. C omplex scraping board blending oar is suitable to every kind of complicated recipe and achieve optimizing effect;

2, Polytetrafluoroethylene scraping board cater to body of blending groove and scrape out viscosity material on boiler wall;

3, H omogenizer is installed on boiler bottom to increase motor power more thoroughly and strongly. During few product ion , I t can exert homogenizing effect fully;

4,Mightiness balance isotactic curve rotor is matched with stator with corresponding structure to realize liquid high-capability cut,rubbing,centrifugal to make sure exquisite and slick product; boiler body and pipe surface mirror polishing 300EMSH (sanitation grade) accords with Daily Chemical and GMP regulation.

5, Main adopts stepless timing device which reduce babble occur under low temperature and high viscosity condition less air bubble will be formed

6. Finished products can be discharged by valve or match a screw pump.

|

Specification(L) |

Volume (L) |

Mixing Power (KW) |

Mixing speed (R/MIN)) |

Homogeneous power (KW) |

Homogeneous speed (R/MIN) |

heating way |

|

JBJ-200 |

200 |

1.5 |

0-65 |

4 |

2890 |

Steam Or electric |

|

JBJ -300 |

300 |

1.5-2.2 |

0-65 |

4 |

2890 |

|

|

JBJ -500 |

500 |

3.0 |

0-65 |

5.5 |

2890 |

|

|

JBJ -1000 |

1000 |

4 |

0-65 |

7.5 |

2890 |

|

|

JBJ -2000 |

2000 |

5.5 |

0-65 |

11 |

2890 |

|

|

JBJ -3000 |

3000 |

7.5 |

0-65 |

18 |

2890 |

|

|

JBJ -5000 |

5000 |

11 |

0-65 |

22 |

2890 |

1.360°rotation high precision PLC control, support formula storage and error prevention management

2.Measure PH/ viscosity/density/concentration online

3.Equipped with CIP cleaning system, automatic cleaning, convenient, sanitary and complete

4.German high shear homogenization technology, multi-stage emulsification

5.80% of main components come from world famous manufacturers (Siemens, ABB, bergman, delixi, etc.)

6.The stirring speed can be adjusted by non-polar frequency conversion, and the materials can be mixed in various ways to make them fully integrated

Guangzhou Yuxiang Light Industry Machinery Equipment Co., Ltd is Head Company of Yangzhou Yuxiang Light Industry Machinery Equipment Factory. We mainly produce vacuum emulsifying machine, liquid washing homogenizing mixer reverse osmosis water treatment, full automatic and semi-automatic filling machine, perfume making machine, labeling machine, printing machine, conveyor. laboratory equipment etc. Our machinery are widely used in cosmetic, pharmaceutical chemical and dairy product and all the machines are in reliable quality and good effect. We have more than 10 years' experience in cosmetic machinery manufacturing and have domestic and overseas markets.

Cerification:

Our product catagories mainly include: Vacuum emulsifying mixer, Liquid washing mixer, Water treatment equipment, Perfume machine, Filling machine, Packing machine, Labeling machine etc. We are able to supply a wide range of high quality products for your One-stop sourcing in our exhibition center.

We attend exhibitions all around the word every year.You are welcomed to see our product and new designed item there .We hope a face to face communicate and service could helpful to our cooperation.

Founded in 2000, with 5 production lines and covering an area of 12,000 square meters, our factory has developed into a professional manufacturer of cosmetics machinery and equipment, by integrating R&D, manafacturing, sales and service. Advanced production equipments are the guarantee for high quality products.

A quality department has been set up to control the product quality during every process of production. For years, we are strictly implementing International Quality Management System ISO 9001.

1 .Q Do you accept a special order?

A: Yes ,we do ; We can manufacture all kinds of chemical equipments according to your technical drawings;

2.Q: Can you give us a quotation right now?

A: Please give us the detail of the technical so we will design and quotate for you as soon as possible;

3.Q: Do you have one in stock?

A:Sorry. We don’t. All products are manufactured according to customer’s requirement;

4.Q: Can you make a design for us?

A:Yes We can What we supply is not only product but also solution and design;

5.Q:Can your engineer come to our place for installation guides?

A:Yes, we can we will provide a video and document for installation;If you still have problems we will send our engineer oversea for installation guide;

For your inquiries, pls kindly let us know:

1. What is your products? Cream,toothpast, moisturizer,night cream, vanishing cream,suncream etc.

2. What is the capacity do you want for this vacuum emulsifying machine? 100L,200L300L,500L,1000L, etc.

3. Required heating method: electric heating or steam heating?

4. Required voltage and frequency of power supply? eg:380V 50Hz 3phase?

5. 5. Requirement of Certificate (CE, UL, CSA, or no need)