- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZD

-

Model Number:

-

ZD-650

-

Voltage:

-

380V,50HZ,3P ,4 L,AC

-

Dimension(L*W*H):

-

19*2.2*2.1m

-

Weight:

-

14000

-

Operators:

-

1-2

-

Max Printing colors:

-

6(1-6 colors supported)

-

Outer layer Material:

-

Kraft Paper(White, brown, yellow, pink etc.)

-

Inner layer Material:

-

Kraft Paper, PE film, Metal Foil Paper

-

Kraft paper gram weight:

-

75-120 gsm

-

Product name:

-

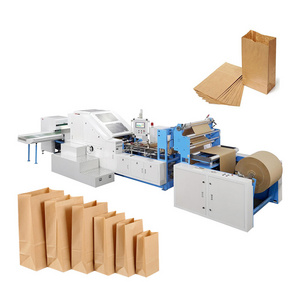

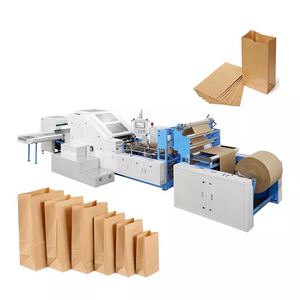

Paper Bag Making Machine With Printing

-

Keywords:

-

Paper Bag Making Machine

-

Certification1:

-

ISO9001

-

Certification2:

-

CE

-

Application:

-

Production of paper bags

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

ALL PAPER BAG

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ZD

-

Model Number:

-

ZD-650

-

Voltage:

-

380V,50HZ,3P ,4 L,AC

-

Dimension(L*W*H):

-

19*2.2*2.1m

-

Weight:

-

14000

-

Operators:

-

1-2

-

Max Printing colors:

-

6(1-6 colors supported)

-

Outer layer Material:

-

Kraft Paper(White, brown, yellow, pink etc.)

-

Inner layer Material:

-

Kraft Paper, PE film, Metal Foil Paper

-

Kraft paper gram weight:

-

75-120 gsm

-

Product name:

-

Paper Bag Making Machine With Printing

-

Keywords:

-

Paper Bag Making Machine

-

Certification1:

-

ISO9001

-

Certification2:

-

CE

-

Application:

-

Production of paper bags

Product Description

|

1).Production capacity

|

Stable speed

--60-100 pcs bag plain end bag tubes / min (the production speed is determined by the bag length and the quality of paper) |

|

2).Finished bag width

|

380-630mm, free adjustment (Customized in bag size range)

|

|

3).Bag side

|

Straight or folding side (“M” side gusset width size: 0-140mm)

|

|

4).Bag length

|

Free adjusted,

PLC servo control the cutting length. Touch screen freely set the length |

|

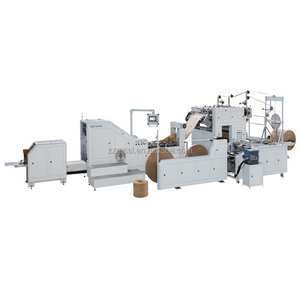

5).Max layers

|

4(1-4 layers supported)

|

|

6).Total Power

|

25 KW

|

|

7).Machine Dimensions

|

Length15m×Width2.4 m× Height 2.1m

|

|

8).Machine weight

|

14 ton(around)

|

|

9).Operators

|

1- 2

|

|

10) .Power supply condition

|

380V,50HZ,3P ,4 L,AC

|

|

11).Control method

|

DELTA servo control system

|

|

12).Outer layer Material

|

Kraft Paper (White, brown, yellow, pink etc.)

|

|

13).Inner layer Material

|

Kraft Paper, PE film, Metal Foil Paper

|

|

14). Kraft paper gram weight

|

75-120 gsm

|

|

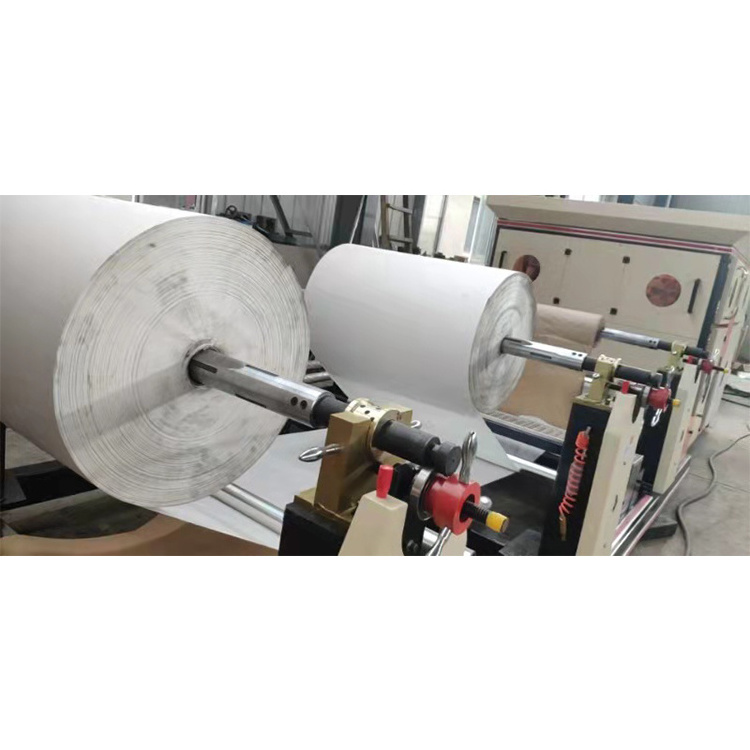

15).Max diameter of paper reel

|

1200mm

|

|

16).Max paper width

|

1250mm

|

|

17).Paper reel inner core diameter

|

76mm

|

|

18). Cutting bags counting

|

Automatic photoelectric counting

|

|

19).In line printer

|

Flexo Stagger Printer

|

|

20). Max Printing colors

|

6(1-6 colors supported)

|

|

Standard configuration

|

Quantity(set)

|

|

Paper roll feeding rack

|

4

|

|

Six color printing unit

|

1

|

|

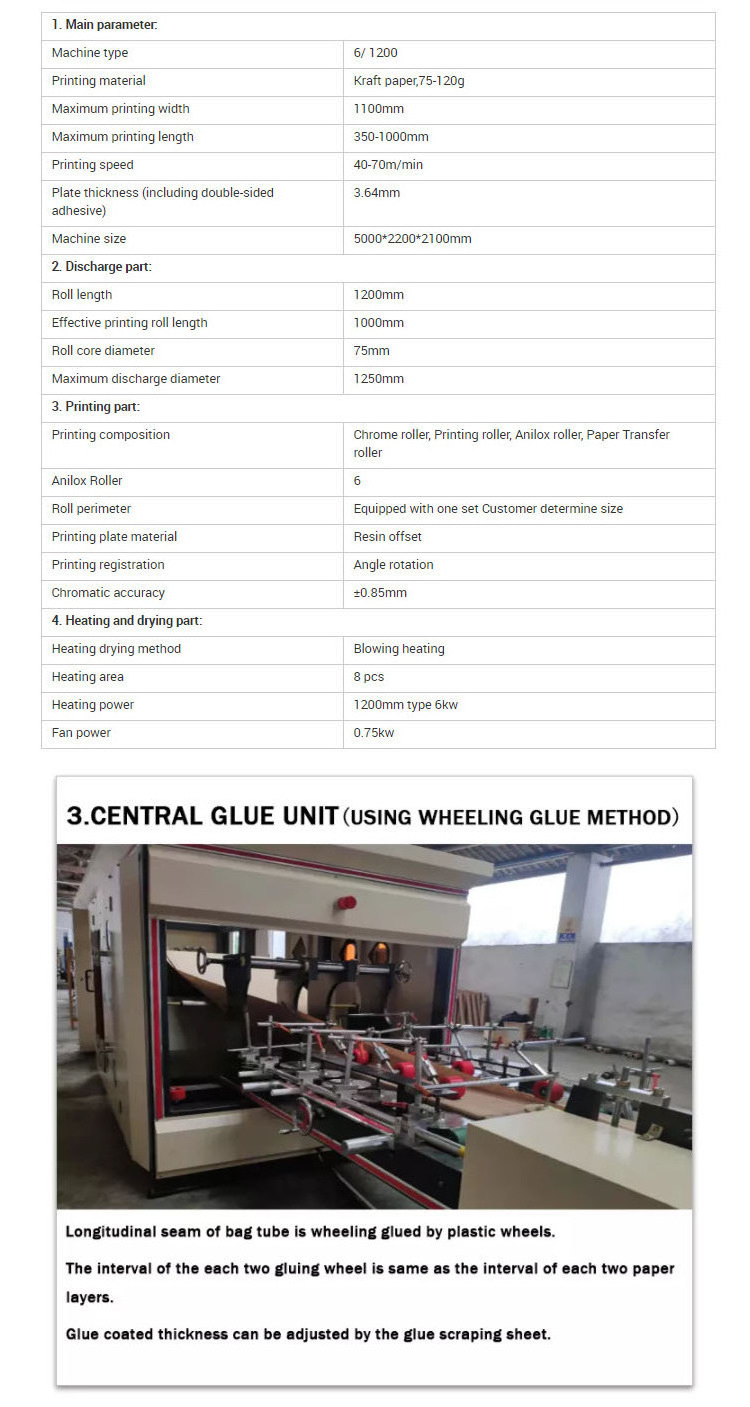

Central glue unit

|

1

|

|

Tube Shaping unit

|

1

|

|

Host unit(Cutting unit)

|

1

|

|

Electric cabinet

|

2

|

Technical service and quality assurance

1. Installation and trial run.

2. The seller's engineer shall guide the equipment placement, install and trial run, give professional advice and train the buyer engineer.

3. Schedule

1). Equipment installation and debugging.

2). spread line and pipeline.

3). Debugging proofreading.

4). Commissioning.

5). Feeding paper trial production.

6). Training (from beginning to end) total time: 4-7 days.

4. Quality assurance period The machine provides a 12 - month warranty period under normal use.

Manufacturer's 5 after-sales guarantees of equipment:

4.1 guarantee to provide the buyer with hardware maintenance and information for accessories and vulnerable parts.

4.2 the seller shall guarantee that each part of the whole machine is new and the machine is not malfunctioning.

4.3 our company has 24-hour online telephone technical guidance to ensure the operation of users.

4.4 if the equipment requires on-site maintenance and debugging after the expiration of the warranty period, the personnel shall

ensure the arrival of on-site treatment within the agreed time.

4.5 the equipment shall be assured for 1 year except for wear.

4.6 after the expiration of the warranty period, the buyer shall provide the maintenance compensation and raw material costs,

transportation expenses, etc.

4.7 the following conditions are not within the 12-month warranty scope.

>Disposable products, such as ink, rubber roller wear and so on.

>Wire aging.

>The worn parts of a machine.

>Change the machine without notifying the seller.

3. Schedule

1). Equipment installation and debugging.

2). spread line and pipeline.

3). Debugging proofreading.

4). Commissioning.

5). Feeding paper trial production.

6). Training (from beginning to end) total time: 4-7 days.

4. Quality assurance period The machine provides a 12 - month warranty period under normal use.

Manufacturer's 5 after-sales guarantees of equipment:

4.1 guarantee to provide the buyer with hardware maintenance and information for accessories and vulnerable parts.

4.2 the seller shall guarantee that each part of the whole machine is new and the machine is not malfunctioning.

4.3 our company has 24-hour online telephone technical guidance to ensure the operation of users.

4.4 if the equipment requires on-site maintenance and debugging after the expiration of the warranty period, the personnel shall

ensure the arrival of on-site treatment within the agreed time.

4.5 the equipment shall be assured for 1 year except for wear.

4.6 after the expiration of the warranty period, the buyer shall provide the maintenance compensation and raw material costs,

transportation expenses, etc.

4.7 the following conditions are not within the 12-month warranty scope.

>Disposable products, such as ink, rubber roller wear and so on.

>Wire aging.

>The worn parts of a machine.

>Change the machine without notifying the seller.

1. Q:How long will your engineer reach our factory?

A:Within one week after everything ready (machine arrival your factory, nonwoven material, power source, air compressor etc.Prepared).

2. Q:How many days will you finish installing ?

A:We will finish installation and training within 15 days.

3. Q:What should we charge for your engineer?

A:You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 80USD one day per person.

4. Q:How long is your machine's warranty period?

A: All our machine have half a years guarantee for electricity parts and one years guarantee for mechanism, starting from finished installation.

5. Q:How could you do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

6. Q:How could you do after one year warranty period?

A:We also can do service for you, but you need pay salary for our technicians 80USD/day for each person.

7. Q:Does your engineer understand English?

A:Our engineers understand a little English. All our engineers have more than five years machine installation experience.

8. Q:Can you help us find any engineer in our location?

A:Of course, we will check and inform you as soon as possible.

9. Q:How do we solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

2. Q:How many days will you finish installing ?

A:We will finish installation and training within 15 days.

3. Q:What should we charge for your engineer?

A:You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 80USD one day per person.

4. Q:How long is your machine's warranty period?

A: All our machine have half a years guarantee for electricity parts and one years guarantee for mechanism, starting from finished installation.

5. Q:How could you do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

6. Q:How could you do after one year warranty period?

A:We also can do service for you, but you need pay salary for our technicians 80USD/day for each person.

7. Q:Does your engineer understand English?

A:Our engineers understand a little English. All our engineers have more than five years machine installation experience.

8. Q:Can you help us find any engineer in our location?

A:Of course, we will check and inform you as soon as possible.

9. Q:How do we solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

Hot Searches