- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HOYSOOK

-

Single Pulse Energy:

-

300J

-

Pulse Width:

-

0.5ms-20ms

-

Wavelength:

-

1080nm

-

Focal Spot Diameter:

-

1.8mm

-

Dimensions:

-

960*550*750mm

-

Weight (KG):

-

150 KG

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

Laser source

-

welding machine:

-

Metal Stainless steel

Quick Details

-

Max. Output Power:

-

3000w

-

Usage:

-

welding Stainless steel metal

-

Laser Source Brand:

-

RAYCUS

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HOYSOOK

-

Single Pulse Energy:

-

300J

-

Pulse Width:

-

0.5ms-20ms

-

Wavelength:

-

1080nm

-

Focal Spot Diameter:

-

1.8mm

-

Dimensions:

-

960*550*750mm

-

Weight (KG):

-

150 KG

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

Laser source

-

welding machine:

-

Metal Stainless steel

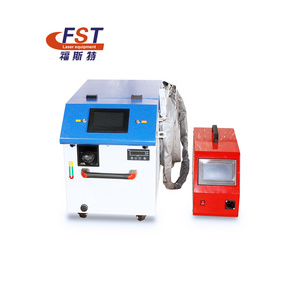

Products Description

|

Model

|

HYLW1000S , HYLW1500S , HYLW2000S , HYLW3000S

|

|

Name

|

Hand-held laser welding machine

|

|

Laser source

|

IPG / Raycus / Max/Reci

|

|

Voltage

|

220V /380V

|

|

Cable length

|

standard 10m,possible :15m

|

|

Laser power

|

1000W, 1500W , 2000W , 3000W

|

|

Wavelength

|

1064/1070 nm

|

|

Working principle

|

continuous or modulated

|

|

Speed range

|

0 ~ 120mm/s

|

|

Water cooler

|

industrial thermostatic water chiller

|

|

Working environment temperature

|

15 ~ 35 ℃

|

|

Humidity of the working environment

|

< 70% No condensation

|

|

Welding thickness / depth

|

0.5-3mm

|

Send inquiry to use , to get the best price and free parts

Application

The field of application of handheld laser welding is very wide. It can be used in various sweat and fields such as automobile sheet metal, chassis, water tank, distribution box and other cabinets, cabinets, kitchen and bathroom, stainless steel door and window guardrails, scaffolding, etc.

Compared with traditional argon arc welding and electric welding processes, hand-held laser welding is energy-saving (about 80% to 90% less electricity than argon arc welding), and the welding speed of metal materials such as thin stainless steel plates, iron plates, and aluminum plates , Welding quality, post-processing (which can greatly reduce the labor cost of polishing and leveling processes), etc., have obvious advantages, so there is a strong potential to replace traditional processes.

Details Images

Hot Searches