- Product Details

- {{item.text}}

Quick Details

-

Pulse Frequency:

-

50/60 HZ

-

Pilot Arc Current:

-

20-120A

-

Rated Duty Cycle:

-

60%

-

Dimensions:

-

125mm*210mm*300mm

-

Use:

-

Welding

-

Voltage:

-

AC220V±15%

-

Power:

-

4.8KVA

-

Weight (KG):

-

2.77 KG

-

Input voltage:

-

220V±15%

-

Frequency(HZ):

-

50/60

-

Rated input power(KVA):

-

4.8

-

Rated input current (A):

-

22.7

-

Rated input capacity (KVA):

-

4.8

-

Rated output voltage (V):

-

24.8

-

No-load voltage(V):

-

62

-

Efficiency(%):

-

60%

-

Current adjustment range (A):

-

20-120

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DELIXI

-

Arc Current:

-

120V

-

Pulse Frequency:

-

50/60 HZ

-

Pilot Arc Current:

-

20-120A

-

Rated Duty Cycle:

-

60%

-

Dimensions:

-

125mm*210mm*300mm

-

Use:

-

Welding

-

Voltage:

-

AC220V±15%

-

Power:

-

4.8KVA

-

Weight (KG):

-

2.77 KG

-

Input voltage:

-

220V±15%

-

Frequency(HZ):

-

50/60

-

Rated input power(KVA):

-

4.8

-

Rated input current (A):

-

22.7

-

Rated input capacity (KVA):

-

4.8

-

Rated output voltage (V):

-

24.8

-

No-load voltage(V):

-

62

-

Efficiency(%):

-

60%

-

Current adjustment range (A):

-

20-120

-

After Warranty Service:

-

Video technical support

1. Digital operation panel and double knob operation can make the welding parameters and operation function more intuitive and more diversified.

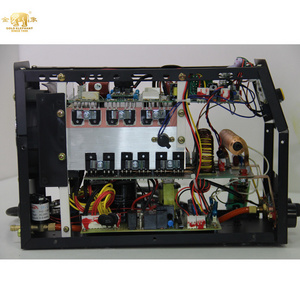

2. Machine is with digital double CPU control technology and soft switch IGBT inverter technology to achieve better welding performance.

3. By modifying and upgrading the control software, it could quickly respond to customers special welding process requirements.

4. Adopt advanced soft switch inverter technology.

5. It is controlled by microcomputer, which is rich in function and easy to maintain.

6. High frequency supercharge arc striking good arc starting performance and arc stability during welding.

7. Unique output characteristics design more suitable for filling wire welding welding beautiful.

8. Built-in overheating overcurrent, overvoltage protection circuit.