- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

cold vulcanizing glue

-

Color:

-

bluish-grey

-

Shelf life:

-

24 Months

-

Material:

-

Polyuerthane

-

Working temperature:

-

≤80℃

-

Feature:

-

non flammable

-

Advantage:

-

Quick

-

Weight:

-

1KG

Quick Details

-

CAS No.:

-

Mixture

-

Place of Origin:

-

Germany

-

Application:

-

conveyor belt repair

-

Product name:

-

cold vulcanizing glue

-

Color:

-

bluish-grey

-

Shelf life:

-

24 Months

-

Material:

-

Polyuerthane

-

Working temperature:

-

≤80℃

-

Feature:

-

non flammable

-

Advantage:

-

Quick

-

Weight:

-

1KG

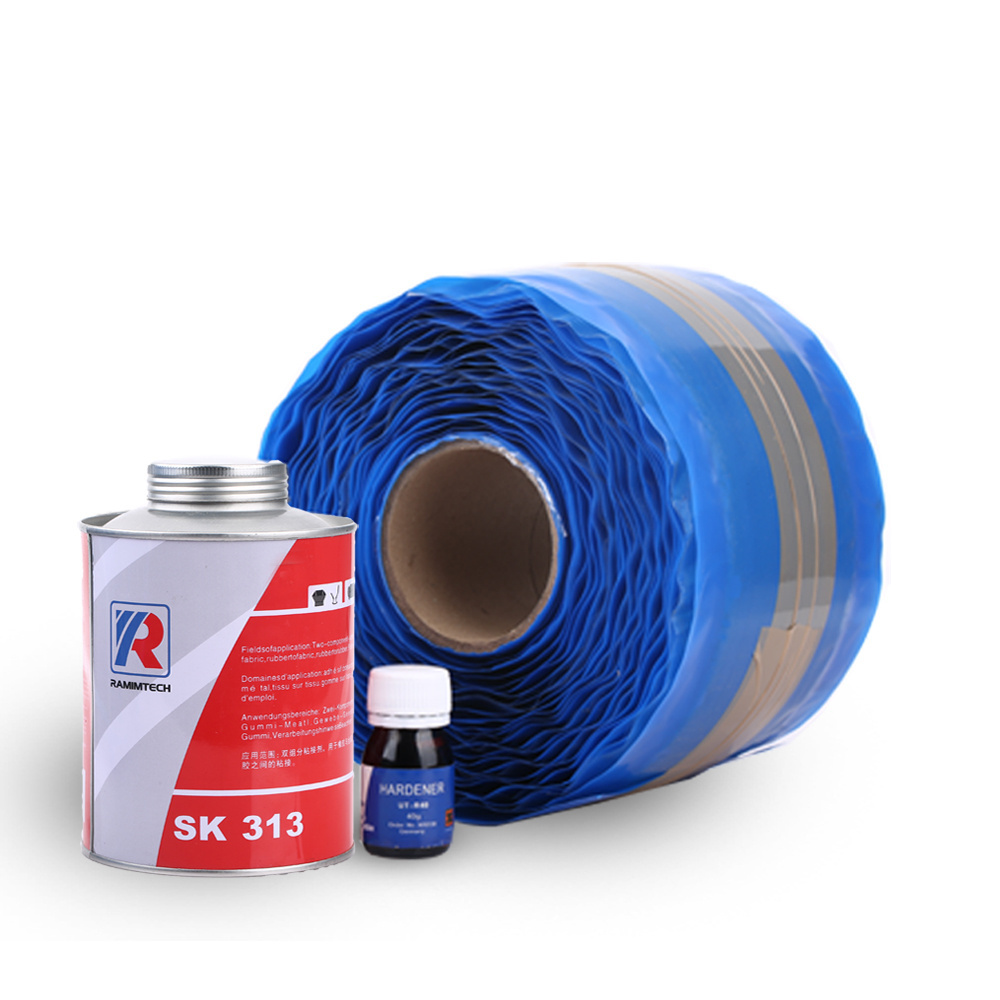

heat resistant rubber conveyor belt repair cold vulcanizing glue

Cold splicing cement SK313 is a kind of bi-component,high performance industrial glue,which has good bonding performance between metal and rubber, rubber and rubber, fabric and rubber, fabric and fabric, also fabric and metal.

Cold splicing cement SK313 is widely used in electricity, coal, mine and cement industry for repairing of rubber conveyor belt,cold seamless jointing and pulley lagging, Belt glue is easy operation, speedy and reliable. Also cold splicing cement SK313 has strong temperature resistance that can reach 100℃, the mixing ratio with hardener is 100:4.

INTERVAL Time

The interval time for Cold vulcanization glue Sk313 depends on the temperature and humidity of internal and external working environment.Before jointing, pls take the glue drying time for reference.

Normal temperature (15℃-30℃) : 35-20 minutes

High temperature:( more than 30℃) : 25-20 minutes

Before jointing, you can test with back side of fingers, if the adhesive has little stickiness, this is the best jointing time.

heat resistant rubber conveyor belt repair cold vulcanizing glue

Rubber Sheet: clean up the semi-curing layer by cleaning solvent if the rubber sheet itself contains, then painting and brushing. Rubber sheet without semi-curing layer will be comprehensive polished by tungsten carbide grinding disc. Then clear dust with hairbrush, clean with cleaning solvent.

Metal: Removal the grease from metal surface with cleaning solvent,then polished with sand wheel or sand blasting. If spread with metal primer SK363, Let it completely dry. Mixed SK313 with hardener with 100:4 and stir evenly, use up in a hour, or this mixture will lose harden efficacy.

Brush- brushing evenly on combination surface with cold splicing cement SK313, spread one layer on rubber sheet ( with BL bonding layer)can joint directly, if rubber sheet without BL layer will brush 2 layers, first layer need totally dry(25 to 30 minutes),and reach the level of not adhering to the back of fingers.When second layer dry to slightly stickiness, then last jointing on surface.

Jointing- paste the sides of combination together, avoid bubble, closely plying-up and compaction.

Suggestions:when pulley lagging, recommend preliminary treating the metal surface by metal primer SK363. Enhancing the bonding strength between rubber and metal.

Attentions

:

1) the temperature of working environment and materials should exceed 5 ℃, surrounding humidness must be less than 90%.

2) The combination surface should be dry and clean, no including grease, engine oil and chemical agent.

3) Above information is based on field experiment, we suggest doing experiment before construction because of different materials and working condition.

4) Unmixed Sk313 and hardener will be sealed in good intact, keep in shady and cool condition.

5) Before solidification, avoid contact with skin, if contact, clean with water and soap immediately.

heat resistant rubber conveyor belt repair cold vulcanizing glue

PACKING:10 SETS PER BOX

10 BOXES PER CARTON

1KG PER SET

OR PACKAGE IT ACCRODING TO CUSTOMER'S REQUEST

DELIVERY: 3-7DAYS

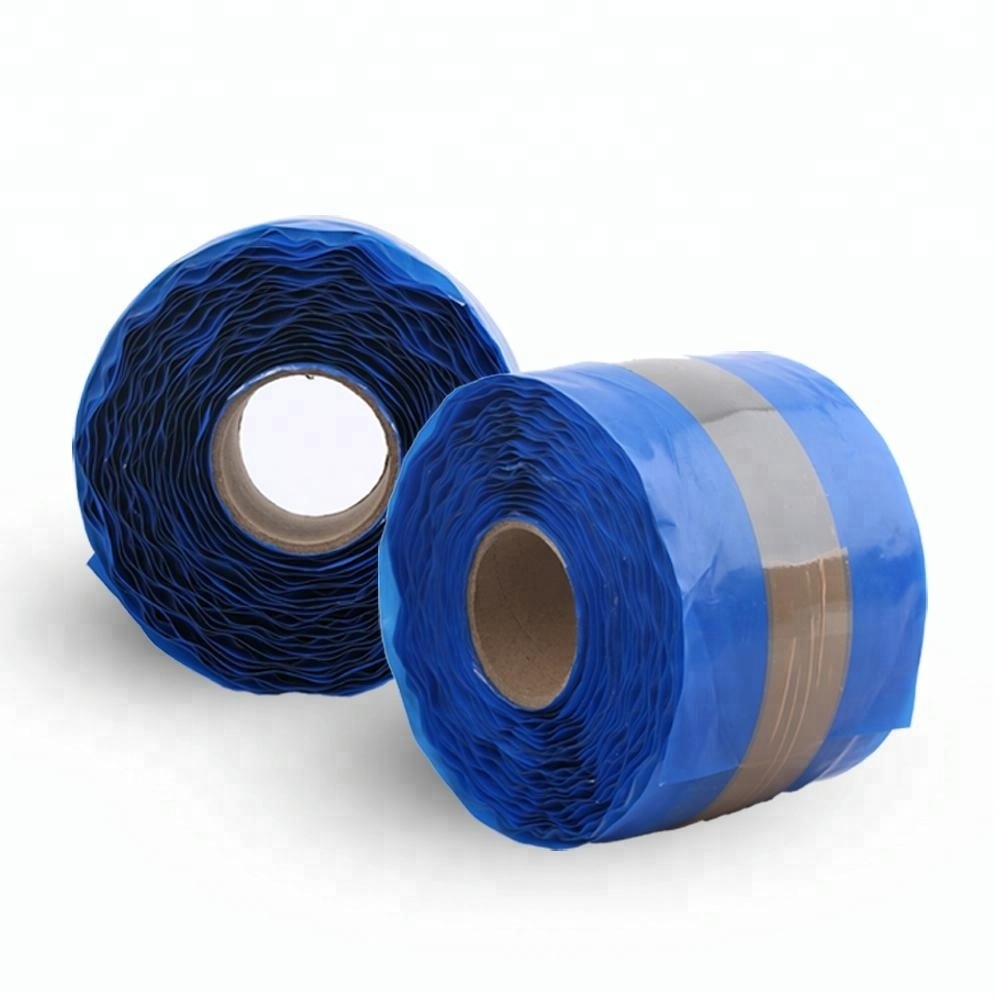

REPAIR STRIP

REPAIR PATCH

INTERMEDIATE RUBBER TIE GUM