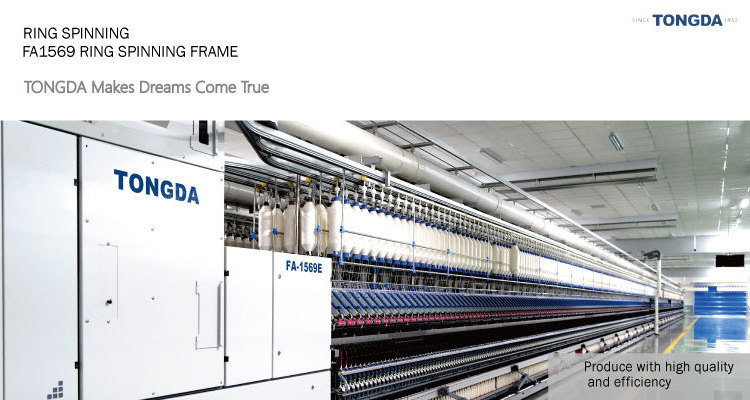

Based on FA538 and FA568, FA1569 serial over-prolongation intelligent ring spinning frame, a new generation basic machine which is leading the development trends with its entire performances reaching inter- national advanced level, integrates quick-in- stalling technology,quick-doffing technology,dual- suctioning technology at both headstock and tailstock, and intelligent spinning expert system. lts energy consumption is reduced by 10% comparing to the current ring

frams.FA1569 is an ideal choice for media-and high-end customers

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGDA

-

Dimension(L*W*H):

-

20300 1150x 2300mm

-

Weight:

-

9000 KG

-

Power:

-

25KW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Number of Spindle:

-

from 612 to 1824 spindles

-

Yarn Count:

-

18-200Ne

-

Spinning Equipment:

-

ring spinning frames

-

MODEL:

-

FA1569

-

Material:

-

Cooton Polyester Polypropylene Nylon Fibers

-

Output:

-

300-700kg/h

-

Tube inserting rale:

-

100%

-

Brand:

-

TONGDA

-

Auto doffing:

-

3 minutes

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Application:

-

Ring frames

-

Production Capacity:

-

99.9%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGDA

-

Dimension(L*W*H):

-

20300 1150x 2300mm

-

Weight:

-

9000 KG

-

Power:

-

25KW

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Number of Spindle:

-

from 612 to 1824 spindles

-

Yarn Count:

-

18-200Ne

-

Spinning Equipment:

-

ring spinning frames

-

MODEL:

-

FA1569

-

Material:

-

Cooton Polyester Polypropylene Nylon Fibers

-

Output:

-

300-700kg/h

-

Tube inserting rale:

-

100%

-

Brand:

-

TONGDA

-

Auto doffing:

-

3 minutes

Product display and advantages

RING SPINNING FRAME

significant advantages

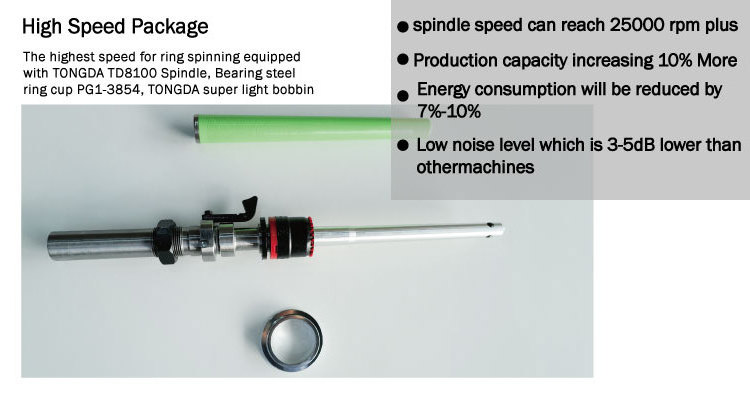

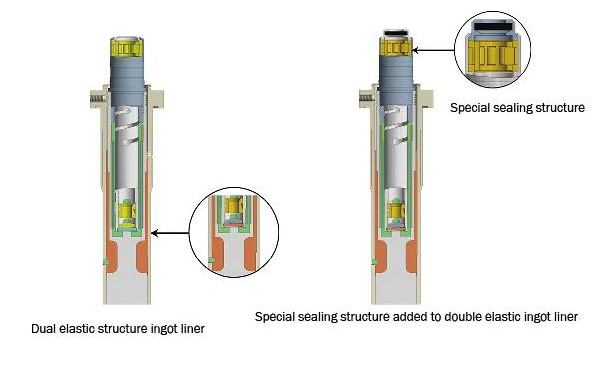

1.Due to special double elasticity structure design, under high-speed spinning conditions, the spindle tube has multi-level shock-absorbing and noise-reducing functions.

2.Multi-level shock absorption can effectively reduce the pressure on the bearings and extend life time of the spindles, under high-speed spinning conditions.

3.Under the same working conditions, compare with other types of spindles, energy consumption is reduced by 7%-10% with TD8100.

4.At a mechanical speed of 25,000rpm, after testing, the noise of this spindle

is 3-5dB lower than other type of spindles.

5. Spindle wharve diameters are available in various specifications: 18.5, 19, 19.5, 20.5

6. Equipped with suitable packages, spindle speed can reach 25000 rpm Plus.

7. Can be equipped with new model yarn grippers.

8. A special sealing structure(patent) is installed with high-quality lubricating oil, and the oil changing cycle is more than 12 months.

2.Multi-level shock absorption can effectively reduce the pressure on the bearings and extend life time of the spindles, under high-speed spinning conditions.

3.Under the same working conditions, compare with other types of spindles, energy consumption is reduced by 7%-10% with TD8100.

4.At a mechanical speed of 25,000rpm, after testing, the noise of this spindle

is 3-5dB lower than other type of spindles.

5. Spindle wharve diameters are available in various specifications: 18.5, 19, 19.5, 20.5

6. Equipped with suitable packages, spindle speed can reach 25000 rpm Plus.

7. Can be equipped with new model yarn grippers.

8. A special sealing structure(patent) is installed with high-quality lubricating oil, and the oil changing cycle is more than 12 months.

Main Technical Data

|

Spindle gauge

|

70

|

|

Spindle number

|

from 612-1824.expanded by unit 36 spindles each

|

|

Roller

|

Φ27XΦ27XΦ27orΦ27XΦ30XΦ27 box length 6 spindles

|

|

Lift

|

160,180(with aluminum spindle)

|

|

Ring diameter mm

|

38,40,42,45(PG type)

|

|

Suitable for fiber length

|

less than 40mm,40-51mm.51-60mm

|

|

Suitable for yarn density Tex(Ne)

|

36.4-4.86(16-120)

|

|

Suitable for Twist(turns per meter)

|

230-3000(Wharf diameter 19)

|

|

Twist direction

|

Z with singletension disc,Z and S with dual tension disc

|

|

Draft

|

Total draft 10-60(standard),total draft10-80(optional)

|

|

Spindle speed r/min

|

12000-25000(mechanical speed with inverter)

|

|

Spinning driving

|

driving by disc

|

|

Drafting type

|

3-lineroller,cradle apron(short)plus bottom apron (long).top weighting

|

|

Lifting type of ring plate

|

arm by electronic lifting

|

|

Twisting type

|

by electronic twisting

|

|

Doffing type

|

Auto-doffing

|

|

Bobbin lifting rate when doffing

|

>99.5%

|

|

Tube inserting rate

|

100%

|

|

None-endbreak rate when auto-doffing finished

|

≥97%(for medium count yarn)

|

|

Auto-doffng duration

|

3 minutes

|

Why Choose Us

Certifications

Exhibition photos

Hot Searches