- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong,China

-

Brand Name:

-

pinjia

-

Voltage:

-

380V

-

Power:

-

1500

-

Dimension(L*W*H):

-

2070*660*750

-

Weight:

-

1150 kg, 1.15t

-

Features:

-

thermal insulation,low cost

-

Product Name:

-

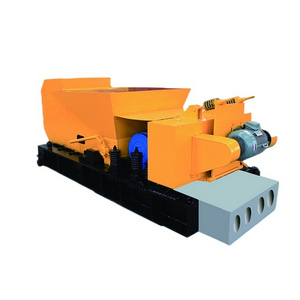

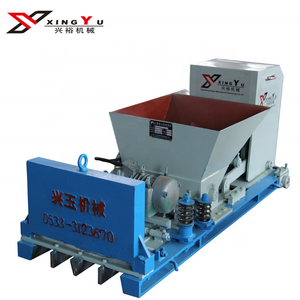

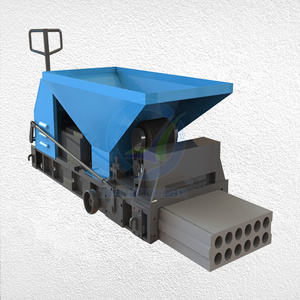

Prefabricated floor slab machine

-

Model:

-

JS-12*50

-

Board height:

-

12

-

Width:

-

50

-

Hole Diameter:

-

4*80mm

-

Plate making speed:

-

≥1.1m/min

-

Main motor:

-

4.0kw

-

Vibrator:

-

ZJY20

-

Overall Dimension:

-

2070*660*750

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Application:

-

Building Material Shops,

-

Production Capacity:

-

≥1.1m/min

-

Place of Origin:

-

Shandong,China

-

Brand Name:

-

pinjia

-

Voltage:

-

380V

-

Power:

-

1500

-

Dimension(L*W*H):

-

2070*660*750

-

Weight:

-

1150 kg, 1.15t

-

Features:

-

thermal insulation,low cost

-

Product Name:

-

Prefabricated floor slab machine

-

Model:

-

JS-12*50

-

Board height:

-

12

-

Width:

-

50

-

Hole Diameter:

-

4*80mm

-

Plate making speed:

-

≥1.1m/min

-

Main motor:

-

4.0kw

-

Vibrator:

-

ZJY20

-

Overall Dimension:

-

2070*660*750

Products Description

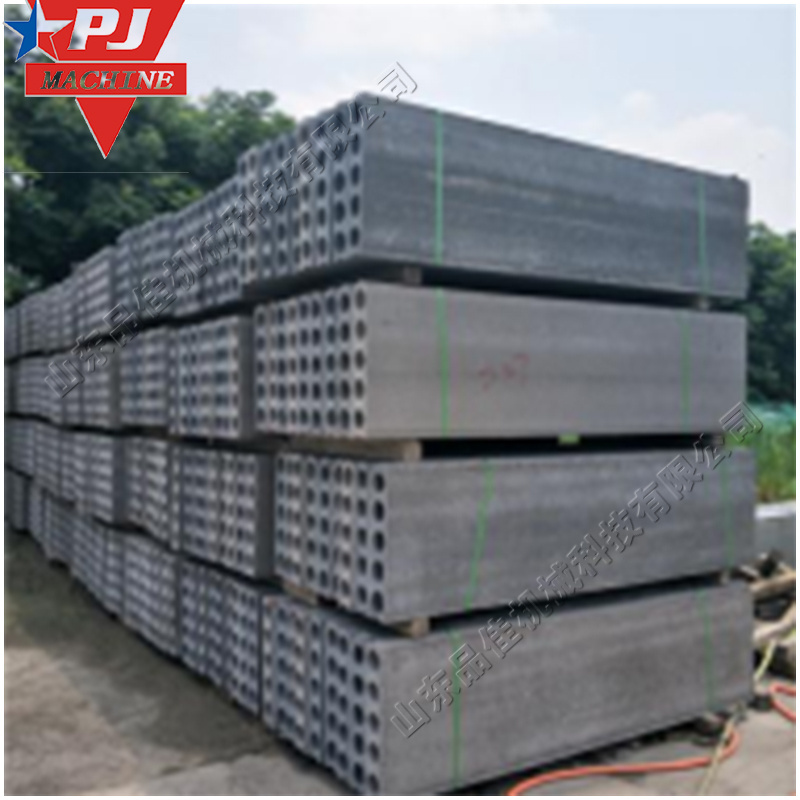

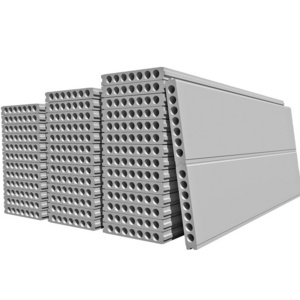

Floor molding machine output of the hollow plate surface smooth, dense inside, strength and geometry can meet the relevant specification requirements, the length of the plate can be 4.2 meters to 18 meters, plate width of 600mm, 900mm, 1200mm, plate thickness of 120mm, 150mm, 180mm, 200mm, 250mm, 300mm, 380mm, is a large workshop, schools, hospitals, shopping malls, office buildings, large warehouses and civil housing and other large-span, high-bearing hollow plate economic, production equipment. It is the economic and production equipment for large-span and high-bearing hollow core plates used in large factories, schools, hospitals, shopping malls, large warehouses, office buildings and civil residences. The machine is technologically advanced, easy and simple to operate, with the addition of lifting, steering, adjusting institutions.

With this machine to produce hollow floor slabs, than with other methods of production (mold pulling, rapid demolding, etc.) efficiency can be increased by 3-5 times, saving cement 30-50kg per cubic meter, reduce the labor intensity of workers, high speed of making boards, dense texture, neat boards, accurate dimensions, the site has a high rate of use and fast turnover, it is the ideal precast component production equipment instead of other methods of production. It is the ideal prefabricated component production equipment instead of other production methods.

Technical parameters

|

Product Name

|

Prefabricated floor slab machine

|

|

Model

|

JS-12*50

|

|

Board height

|

12

|

|

Width

|

50

|

|

Hole Diameter

|

4*80mm

|

|

Plate making speed

|

≥1.1m/min

|

|

Main motor

|

4.0kw

|

|

Vibrator

|

ZJY20

|

|

Overall Dimension

|

2070*660*750

|

|

Weight

|

1.15t

|

Product Photos

Customer visit&evaluation

FAQ

Are you manufacture?

Yes. We are one of leading manufacturers

Do you have stock productions to sell?

Yes,of course.But we also offer OEM service. Please send us some drawing.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production time for

punctual delivery.

(2) 20year production experience. We have over 20 years experience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad

situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to

discuss with him for all the problems and the way sames much times.

The picture of the machine is for reference only. The actual machine is subject to customer order.

Yes. We are one of leading manufacturers

Do you have stock productions to sell?

Yes,of course.But we also offer OEM service. Please send us some drawing.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production time for

punctual delivery.

(2) 20year production experience. We have over 20 years experience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad

situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to

discuss with him for all the problems and the way sames much times.

The picture of the machine is for reference only. The actual machine is subject to customer order.

Product packaging

Hot Searches