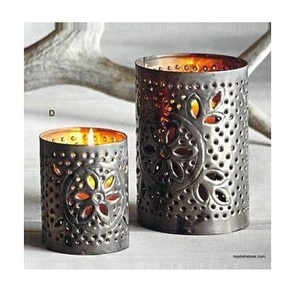

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AWO

-

Model Number:

-

CH05

-

Product name:

-

Canldle Holder

-

Usage:

-

Home Decoration Wedding Decoration

-

Size:

-

Customized Sizes

-

Color:

-

Customized

-

Sample Time:

-

5-7days

-

Packing:

-

Standard

-

MOQ:

-

100pcs

-

Logo:

-

Customized Logo

-

Payment:

-

T/T30% 70%

-

OEM & ODM:

-

Highly Welcomed

Quick Details

-

Use:

-

Home Decoration

-

Handmade:

-

Yes

-

Place of Origin:

-

Uttar Pradesh, India

-

Brand Name:

-

AWO

-

Model Number:

-

CH05

-

Product name:

-

Canldle Holder

-

Usage:

-

Home Decoration Wedding Decoration

-

Size:

-

Customized Sizes

-

Color:

-

Customized

-

Sample Time:

-

5-7days

-

Packing:

-

Standard

-

MOQ:

-

100pcs

-

Logo:

-

Customized Logo

-

Payment:

-

T/T30% 70%

-

OEM & ODM:

-

Highly Welcomed

Product Description

Specification

|

ITEM

|

VALUE

|

|

Place of Origin

|

India

|

|

|

Uttar Pradesh

|

|

Brand Name

|

Antique World Overseas

|

|

Type

|

Candle Votive

|

|

Use

|

Home Decoration

|

|

Occasion

|

Christmas

|

|

Handmade

|

Yes

|

|

Metal Type

|

Metal

|

|

Printing

|

Letterpress printing, Embossing printing, Die cutting printing

|

|

Print Method

|

Customized

|

|

Product name

|

Candle Stand

|

|

Use

|

Christmas

|

|

Metal Type

|

Aluminum, Brass Copper Steel

|

|

Usage

|

Home Lighting Decoration

|

|

Color

|

Customized Color Acceptable

|

|

Material

|

Metal:iron

|

|

Size

|

Customized Sizes

|

|

MOQ

|

100pcs

|

|

Packing

|

Carton

|

|

Logo

|

Customized Logo Accept

|

Manufacturing Technique

Polishing Process

Polishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment

, leaving a clean surface with a significant specular reflection.

Polishing is often used to enhance the appearance of an item, prevent contamination of instruments, remove oxidation, create a reflective surface, or prevent corrosion in pipes. In metallography and metallurgy, polishing is used to create a flat, defect-free surface for examination of a metal's microstructure under a microscope. Silicon-based polishing pads or a diamond solution can be used in the polishing process. Polishing stainless steel can also increase its sanitary benefits.

Electro Plating

Electroless deposition (ED)

or electroless plating is defined as the autocatalytic process through which metals and metal alloys

are deposited onto conductive and nonconductive surfaces. These nonconductive surfaces include plastics, ceramics, and glass etc.

which can then become decorative, anti-corrosive, and conductive depending on their final functions. Electroplating unlike electroless deposition only deposits on other conductive or semi-conductive when a external current is applied. Electroless deposition deposits metals onto 2D and 3D structures such as screws, nanofibers, and carbon nanotubes unlike other plating methods such as Physical Vapor Deposition ( PVD), Chemical Vapor Deposition (CVD), and electroplating which are limited to 2D surfaces.

are deposited onto conductive and nonconductive surfaces. These nonconductive surfaces include plastics, ceramics, and glass etc.

which can then become decorative, anti-corrosive, and conductive depending on their final functions. Electroplating unlike electroless deposition only deposits on other conductive or semi-conductive when a external current is applied. Electroless deposition deposits metals onto 2D and 3D structures such as screws, nanofibers, and carbon nanotubes unlike other plating methods such as Physical Vapor Deposition ( PVD), Chemical Vapor Deposition (CVD), and electroplating which are limited to 2D surfaces.

Hydraulic Press

Only small-diameter tubing (which more easily resists pressure) is needed if the pump is separated from the press cylinder.

Hydraulic presses are commonly used for forging, clinching, molding, blanking, punching, deep drawing, and metal forming operations. Hydraulic presses are also used for stretch forming, rubber pad forming, and powder compacting.The hydraulic press is advantageous in manufacturing, it gives the ability to create more intricate shapes and can be economical with materials A hydraulic press will take up less space compared to a mechanical press of the same capability. The hydraulic press depends on (Pascal's principle).The pressure throughout a closed system is constant. One part of the system is a piston acting as a pump, with a modest mechanical force acting on a small cross-sectional area; the other part is a piston with a larger area which generates a correspondingly large mechanical force.

Product packaging

Certifications

Hot Searches