- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Customized:

-

Yes

-

Cycle:

-

6pcs or more

-

Direct Factory:

-

Yes

Quick Details

-

Type:

-

Interlock Block Making Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

50000-4000000

-

Place of Origin:

-

Shandong, China

-

Customized:

-

Yes

-

Cycle:

-

6pcs or more

-

Direct Factory:

-

Yes

KELLY WANG 008615305399023 SKYPE:KELLYBLOCK88

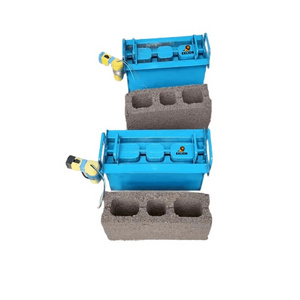

Introduction of manual moulds for foam concrete blocks/manual moulds for foam concrete interlock blocks

It is the ultimate green building block . It is precision molded, interlocking, mortarless and requires little skill to lay.

Details of manual moulds for foam concrete blocks/manual moulds for foam concrete interlock blocks

Eco-lite block is made with cellular lightweight concrete. A non-toxic chemical foam is introduced into regular concrete leaving a multitude of air pockets within the mixture. This wet mixture is poured into block molds and allowed to cure.

No heat is employed during the manufacturing process. The molds are disassembled revealing lightweight blocks comprised of Fly ash/sand and cement filled with non-interconnected air pockets.

During construction, reinforced steel (rebar) and grout are introduced into some of the holes within the blocks to form columns. It is these columns that provide the support for the structure.

The structure essentially represents a basic column and beam system with the columns and beams being made out of materials that structural engineers are already familiar with.

The mortarless design creates gaps between blocks which act as expansion joints eliminating the need for such.

Although Liteblok walls are structural, the blocks themselves are not structural elements. Liteblok is a form that contains the structure.

Adventages of

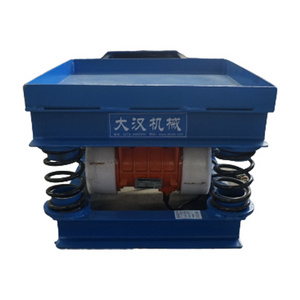

Eco-lite blok,cellular lightweight concrete block making machines

Comparison between CLC&AAC Blocks:

Production process of manual moulds for foam concrete blocks/manual moulds for foam concrete interlock blocks

Finished Molds at Factory:

Packing & Shipping:

Packing:Nude or Iron Box

Delivery Time:30 days after the receipt of the down payment

Shipping Port: Qingdao, China

We have our long-term and reliable freight forwarder, which could guarantee to provide our customer with best service, but we could also use the clien's nominated freight agent as required.

Aftersale Services:

Selling is only the beginning of our service

1, Our good after-sale service would provide our customer with both the technology and the skills.

2 , Our overseas technicians would be there to help installation and teach the using method.

3, We could provide the manual brochure if needed.

4, We would provide professional help with plant building by providing the foundation drawing.