- Product Details

- {{item.text}}

Quick Details

-

Power:

-

1.5kw

-

Dimension(L*W*H):

-

1500*980*1600MM

-

Weight:

-

75 kg, 75 kg, 75-120Kg

-

Function:

-

Coalescence dehydration purifier

-

Oil machinery:

-

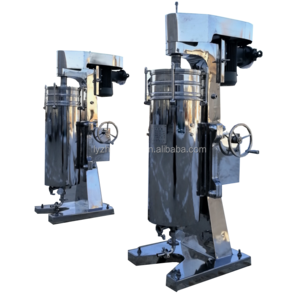

High precision coalescence dehydration oil filter machine

-

Name:

-

Oil filter machine

-

Operating temperature:

-

0----80

-

Accuracy:

-

NASI638 5-7 level

-

Dimension(L*W*H)::

-

1500*980*1600

Quick Details

-

Flow:

-

100L/min, 0.75-2.2Kw

-

Place of Origin:

-

henan

-

Voltage:

-

380V, 380V 50HZ 3P (Customizable), AC380V (3 Phase) /220V

-

Power:

-

1.5kw

-

Dimension(L*W*H):

-

1500*980*1600MM

-

Weight:

-

75 kg, 75 kg, 75-120Kg

-

Function:

-

Coalescence dehydration purifier

-

Oil machinery:

-

High precision coalescence dehydration oil filter machine

-

Name:

-

Oil filter machine

-

Operating temperature:

-

0----80

-

Accuracy:

-

NASI638 5-7 level

-

Dimension(L*W*H)::

-

1500*980*1600

High Vacuum Transformer Oil Regeneration Insulation Oil Filter Machine

Vacuum oil filtration equipment is one of the new generation oil purifying series, researched on the basis of the technology in domestic and oversea. It can remove the air, water and mechanical impurity from oil so as to meet the oil operation standard. Also, it operates simply.

|

Working principle |

The vacuum oil filtration equipment researched by our company has the function of precision filtration and efficient dehydration, removing the particles , emulsion water and free water effectively.

|

|

Working Process |

The dirty oil runs into the system from the entrance ball valves under negative pressure, go through the absorption oil filter to remove the coarse particles to protect the pump, then heated by the heaters step by step to a permanent temperature controlled by the automatic temperature control unit ,comes to the vacuum separator to fall down by the allotter. It forms a oil film by he packing material, and the moisture and air in the oil liquid are boiled out of the vacuum environment, making the separation of oil and water. Most of the steam runs into the steam trap to be water, and the rest escape out of the vacuum pump together with the volatile air. The oil liquid without moisture runs out of the oil drain pump, filtered by two steps high precision for the delicate particles, and drain our from the oil pump to finish a working recycling. |

Performances & Technology Parameter:

1. Performance: emulsification, degassing, dehydration, purify the mechanical impurity.

2. Applicable scope: medium and low viscosity hydraulic oil and lubricating oil.