- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

30*10*10m

-

Power (kW):

-

24 kW

-

Weight (KG):

-

35000 KG

-

Name:

-

Discount excellent used tire extracting pyrolysis oil plant for sale

-

Heating Style:

-

Hot air&Directly

-

Material:

-

Q245R Boiling Steel

-

Cooling:

-

Shock Water Cooling

-

Output Rate:

-

45-50%+5%(Specific Tech)

-

Environmental:

-

Meet to European standard

-

Life span:

-

5-8 years

-

Capacity:

-

6T/D

-

Application:

-

Pyrolysis of waste tyre, plastic etc.

-

Fuel:

-

Coal, oil, wood, natural gas

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhong Yu

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

30*10*10m

-

Power (kW):

-

24 kW

-

Weight (KG):

-

35000 KG

-

Name:

-

Discount excellent used tire extracting pyrolysis oil plant for sale

-

Heating Style:

-

Hot air&Directly

-

Material:

-

Q245R Boiling Steel

-

Cooling:

-

Shock Water Cooling

-

Output Rate:

-

45-50%+5%(Specific Tech)

-

Environmental:

-

Meet to European standard

-

Life span:

-

5-8 years

-

Capacity:

-

6T/D

-

Application:

-

Pyrolysis of waste tyre, plastic etc.

-

Fuel:

-

Coal, oil, wood, natural gas

Eco technique waste tires pyrolysis to oil equipment retreaded tyre production line

Products Description

ZY, as one of the leading suppliers of charcoal making machine in China, grasps the advanced technology, the best resources, and the strongest team of manufacturing, engineering, marketing, and service. Meanwhile, we’ll never forget the original intention to produce this machine, focus more on the improving of it and let more people in the world know the meaning of making charcoal from waste.

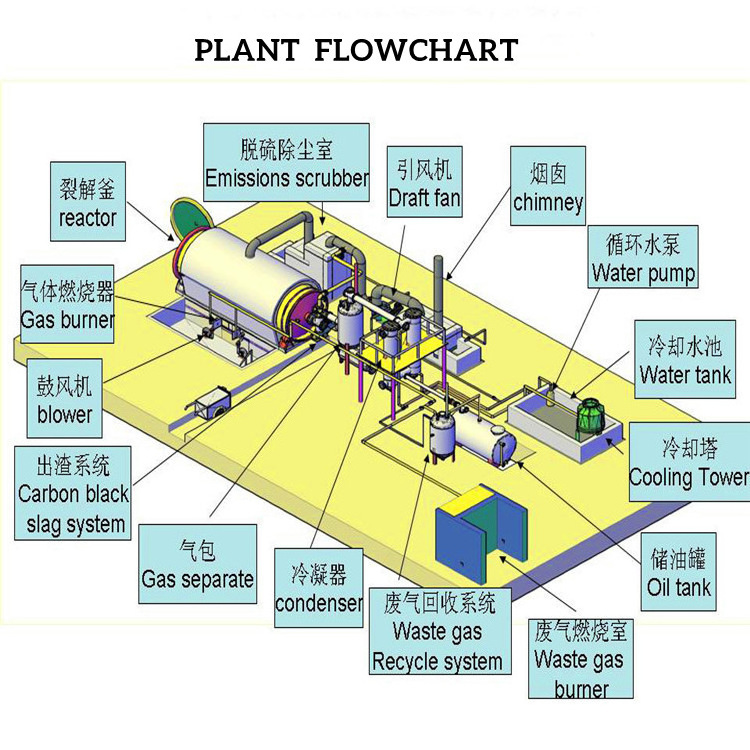

Pyrolysis machine is designed for recycling waste tire/plastic/rubber/oil sludge into fuel oil to replace landfill or incineration which causes serious environmental pollution. The main output product is fuel oil that finds good market in industrial field.

Solid Waste Pyrolysis Plant

Solid Waste pyrolysis equipmented with safety device(alarm for over temperture and pressure, auto pressure releasing system, extra gas recycling system, fire fighting decvice) and advaced dedusting system(dust chenical removing tank, ceramic ring filtering system and alkali sprayers), which will guarantee safety and no pollution in production.

|

Model

|

ZY-6

|

ZY-10

|

ZY-16

|

ZY-20

|

|||

|

Daily Capacity

|

6MT

|

8-10MT

|

15-20MT

|

20-24MT

|

|||

|

Working Method

|

Batch

|

|

Semi-Continuous

|

Fully Continuous

|

|||

|

Raw Materials

|

Wast Plastic,Tyre,Rubber,Oil Sludge

|

|

|

|

|||

|

Reactor Size

|

D2.2*L6.0m

|

D2.6*L6.6m

|

D2.8*L7.1m

|

D1.4*L11m

|

|||

|

Pattern

|

Horizontal&Rotary

|

|

|

|

|||

|

Heating Materials

|

Charcoal,Wood,Fuel Oil,Natural Gas,LPG,etc.

|

|

|

|

|||

|

Total Power

|

24kw/h

|

30kw/h

|

54kw/h

|

71.4kw/h

|

|||

|

Floor Area(L*W*H)

|

30*10*10m

|

30*10*8m

|

40*10*8m

|

45*25*10m

|

|||

|

Operating Pressure

|

Normal Pressure

|

|

Constant Pressure

|

|

|||

|

Cooling Method

|

Water Cooling

|

|

|

|

|||

|

Life Span

|

5-8 Years

|

|

|

|

|||

Packing&Shipping

Company Introduction

FAQ

1.Can we process mixed material of tire and plastic?

We don't advise it, because they have different oil yield rate and quality.

2.Is ZY-16 Pyrolysis Plant a BATCH system?

No, semi-continuous with pretreating system.

3.Also can this plant take all types of waste plastic?

Except PET and PVC, the rest can be deal with.

4.What's the advantage of " Three in one"?

Oil tank, oil condenser,hydraseal Save installation time and land; with good cooling effect

5.Does the reactor use the burnable gases generated by the pyrolysis process as additional fuel to heat the reactor?

Yes.The combustible gas generated during the pyrolysis process after the hydroseal desulfurization and imputoty removal, can be used as fuel heating the reactor.

6.Are there other locations. I saw an office in Canada. Is that correct?

We have set up branches and overseas warehouses in Russia, Pakistan and Uzbekistan.

Hot Searches