- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v 50hz 3Phase or Customized

-

Dimension(L*W*H):

-

About 2600*1800*1200mm(ACS300/80)

-

Weight:

-

5000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

application:

-

Plastic pelletizing machine

-

Fits for:

-

PVC,PP,PE film,LDPE flakes(more than 10 kind of material)

-

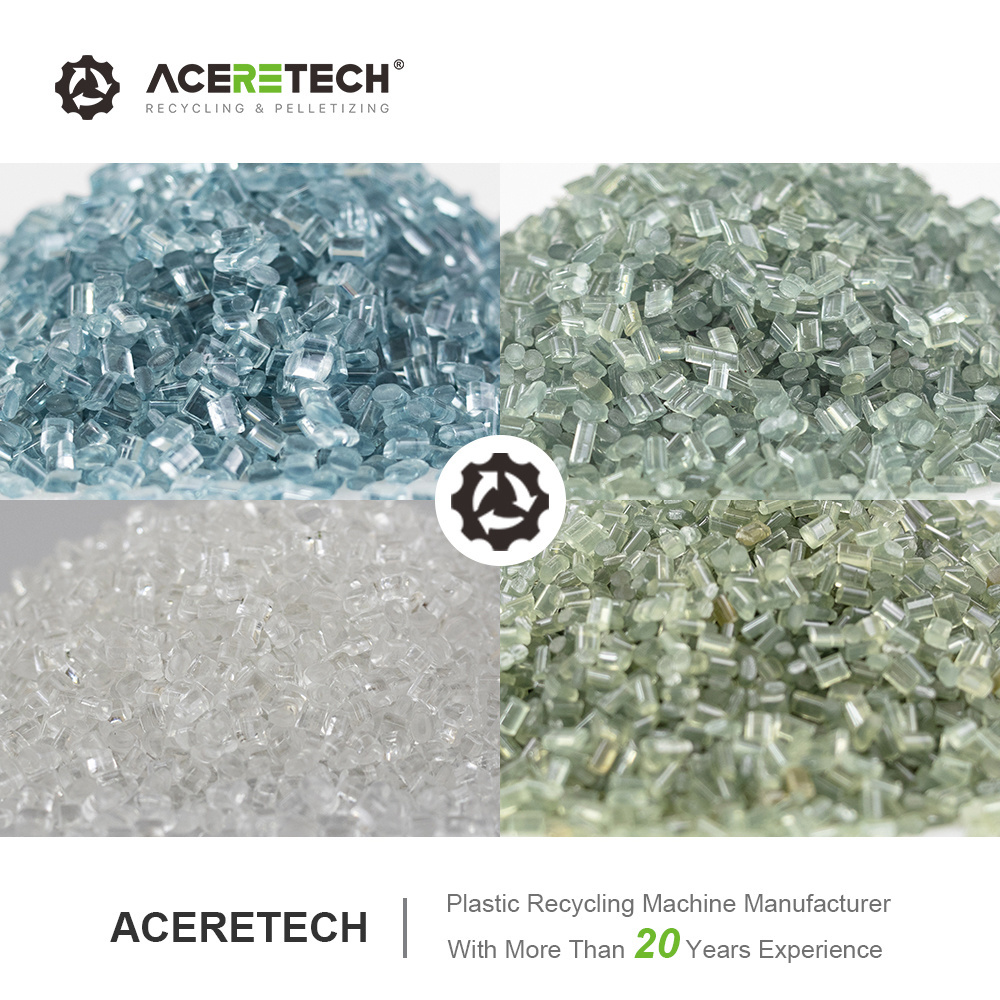

Final product:

-

Pellets/granules

-

Cutting way:

-

Water-ring Die-face, Strand, Underwater

-

Melt filter:

-

Plate, Column/Piston,laser filter

-

PLC intelligent control system:

-

Schneider/Siemens

-

Machine test support:

-

Yes, with clients' materials

-

Screw:

-

Single/Double

-

Capacity:

-

160-1200kg/h

Quick Details

-

Output (kg/h):

-

150 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACERETECH

-

Voltage:

-

380v 50hz 3Phase or Customized

-

Dimension(L*W*H):

-

About 2600*1800*1200mm(ACS300/80)

-

Weight:

-

5000

-

Screw Speed (rpm):

-

1 - 600 rpm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

application:

-

Plastic pelletizing machine

-

Fits for:

-

PVC,PP,PE film,LDPE flakes(more than 10 kind of material)

-

Final product:

-

Pellets/granules

-

Cutting way:

-

Water-ring Die-face, Strand, Underwater

-

Melt filter:

-

Plate, Column/Piston,laser filter

-

PLC intelligent control system:

-

Schneider/Siemens

-

Machine test support:

-

Yes, with clients' materials

-

Screw:

-

Single/Double

-

Capacity:

-

160-1200kg/h

Product Description

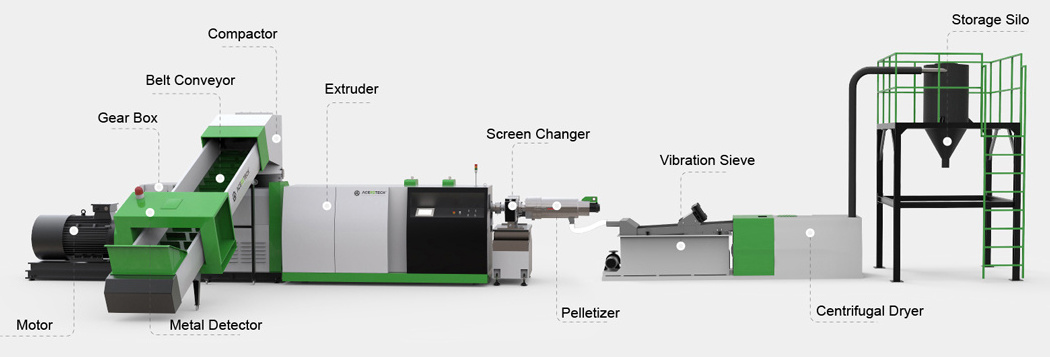

To meet the market demand, ACERETECH developed and launched environmental 3 in 1 integrated plastic granulation recycling system--ACS-HTM COMPACTING AND PELLETIZING MACHINE.

It is different from traditional granulation line.This ACS-HTM smart plastic recycling pelletizing machine pays more attention to protecting the physical properties of environmental plastics, can maintain the plasticity, toughness and durability of the original environmental plastics as far as

possible.

Aceretech Recyclable Plastics Include

●PP/PE film/ industrial film/ post-cosumer film

●LDPE/HDPE bags

●Soft material

●PP woven bag

●PP non-woven/baby diaper non woven

●EPS/XPS foam material/ Fish box foam material/ Package foam material

●PET/Nylon PA6 PA66 film/fiber/filament/fiber cloth

●PP/PE/ABS/PS/PC flakes/regrinds

●PVB film/flakes

Suitable Products

Product Paramenters

|

SPECIFICATIONS

|

|

|

|

Machine Model

|

ACS

|

|

|

Target Recycled Material

|

HDPE, LDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, ABS

|

|

|

Final Product Shape

|

Particles

|

|

|

System composition

|

Belt Conveyor, Cutting Compactor, Single Screw Extruder, Filtration, Pelletizer, Water Cooling Device, Dehydration Section,

Conveyor Fan, Product Silo.

|

|

|

Output Range

|

150kg/h-1200kg/h

|

|

|

Feeding Device

|

Belt Conveyor (Standard), Roll Hauling off device (Optional)

|

|

|

Compactor Volume

|

300L-1400L

|

|

|

Diameter of screw

|

80mm-180mm (Standard)

|

|

|

Material of screw

|

38CrMoAlA (SACM-645), Bimetal (Optional)

|

|

|

L/D of screw

|

31/1, 32/1, 34/1, 36/1 (According to the characteristics of recycling)

|

|

|

Heater of barrel

|

Ceramic heater or Far-infrared heater

|

|

|

Cooling of Barrel

|

Air cooling of fans through blowers

|

|

|

Vacuum deashing exhaust

|

Two Double-zone vacuum degassing system (Standard)

|

|

|

Pelletizing type

|

Water-ring pelletizing/ water-strands pelletizing/ Under-water pelletizing

|

|

|

Voltage Standard

|

According to the Voltage of the Customer's Location

|

|

|

Optioanl device

|

Metal detector, Roll

huali

ng off device, Masterbatch and additives feeder

|

|

|

Warranty

|

13 months from the date of bill of lading

|

|

|

Technical services

|

project design, factory construction, installation and recommendations, commissioning

|

|

|

Model

|

ACS-H

300/80

|

ACS-H

500/100

|

ACS-H

800/120

|

ACS-H

1000/140

|

ACS-H

1200/160

|

ACS-H

1400/180

|

|

Compactor Volume (L)

|

300

|

500

|

800

|

1000

|

1200

|

1400

|

|

Compactor motor

|

37

|

55

|

90

|

110

|

132

|

160

|

|

Screw diameter(mm)

|

80

|

100

|

120

|

140

|

160

|

180

|

|

L/D ratio

|

42

|

42

|

42

|

42

|

42

|

42

|

|

Power(kw)

|

45/55

|

90/110

|

132

|

160/185

|

220/250

|

315

|

|

Productivity(kg/h)

|

160-220

|

300-380

|

450-500

|

500-650

|

800-1000

|

1000-1200

|

Product Detail

FEEDING &COMPACTING

>>> Plastic scraps such as film, filament, raffias conveyed into the compacting room through belt conveyor;

>>> To handle rolls’ scraps, roll hauling off device is an optional feeding method;

>>> Motor drives of conveyor belt and hauling device cooperate with ABB inverter;

>>> Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor’s room is.

EXTRUSION & DEGASSING

>>> Specialized single screw extruder:

Equipped with high torque gearbox with integrated design; 34D to 36D processing section to gently melt the plastics.

>>> Double-zone vacuum degassing system:

Remove the volatiles efficiency;Equipped with vacuum tank, which store the impurities, small molecules or oil stains from the exhaust.

MELT FILTRATION

>>> Plate type double station filter:

Cost - effective,Easy to operate.

>>> Piston type large area filter:

Suitable for heavy contaminated material;

Suitable for large capacity recycling machine.

>>> SCF type Self-clean filter:

No need to change the mesh screen;

Automatically discharge the impurities;

Can realize 60mesh, 80mesh 100mesh and 120mesh.

PELLETIZING SYSTEM

>>> Water-ring pelletizing system:

>>> Standard granulating method in ACS-H system;

>>> Self-adjusting pelletizing head ;

>>> RPM of rotatory blades is automatic.

PELLETIZING SYSTEM

>>> Under-water pelletizing system:

>>>

Suitable for big capacity, automatically;

>>>

Applicable to a wider range of materials.

PELLETIZING SYSTEM

>>> Water-strands pelletizing system:

>>>

Cost-effective;

>>>

Suitable for the material which MFI is higher than 8.

DRYING & PACKING SYSTEM

>>> Vibration

dryer

:

Sieve is made of Stainless steel;

Dewatering granules and selecting size.

>>> Centrifugal dryer:

Blower on the dryer to remove the moisture further.

>>> Product silo:

All pipes and silos wrapped with sound-proofing cotton;Optional Capacity online monitoring & Quantitative weighing.

INTELLIGENCE OPERATING

>>> Intelligence Start: One button only;

>>> Intelligence Stop: One button only;

>>> Emergency Stop: One button only;

Remote monitoring and information transmission.

Company Video

Hot Searches