- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

SUNWAY

-

Voltage:

-

380v

-

Power:

-

55kw

-

Weight:

-

30000 kg

Quick Details

-

Marketing Type:

-

Hot Product

-

Production Capacity:

-

10~40m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SUNWAY

-

Voltage:

-

380v

-

Power:

-

55kw

-

Weight:

-

30000 kg

Product Description

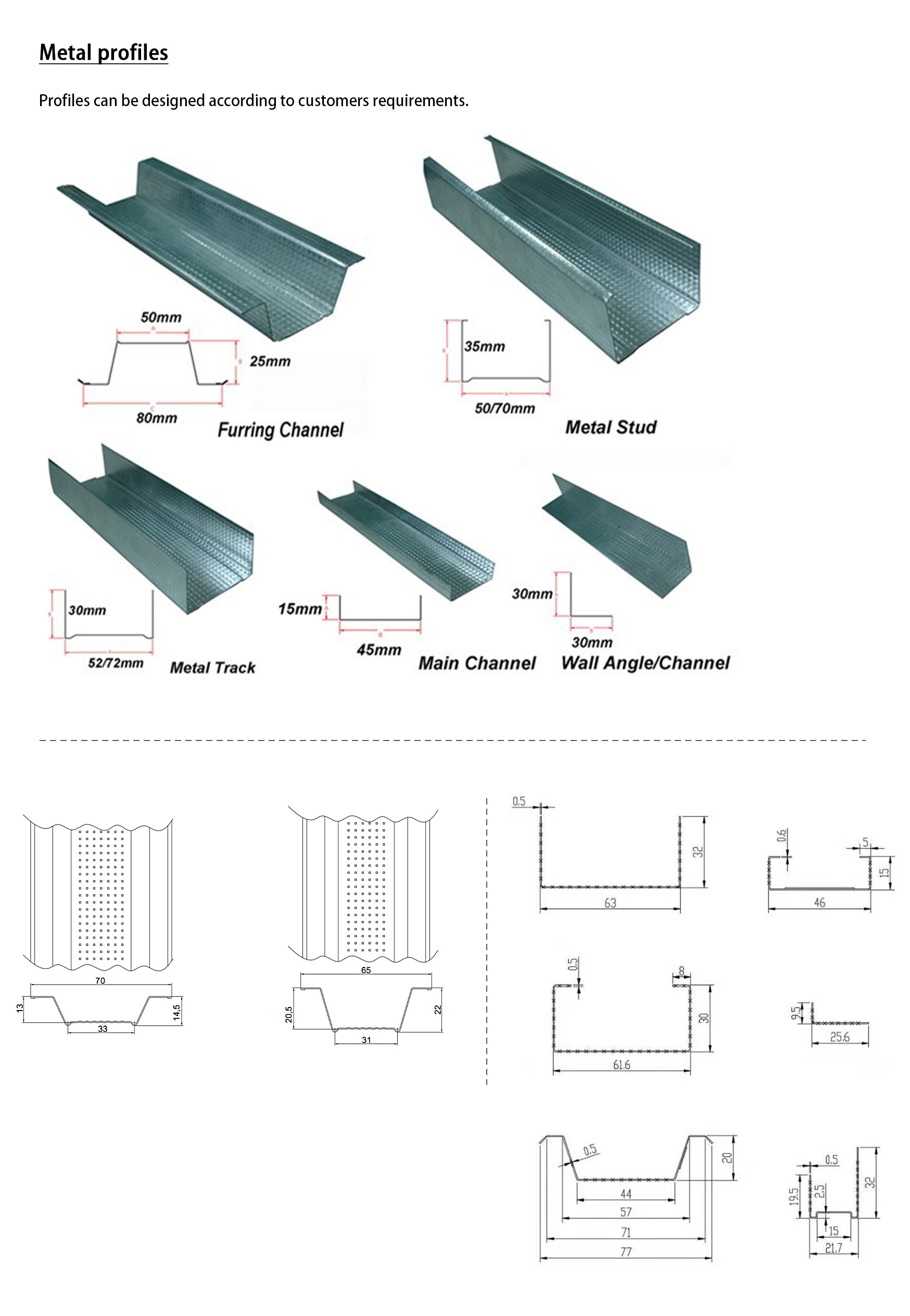

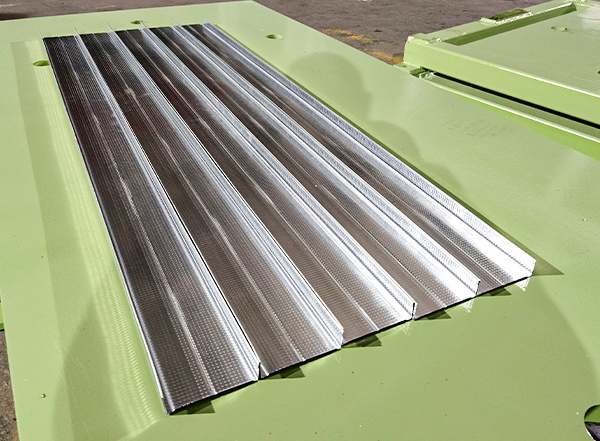

Light Gauge steel roll forming machine is the most popular machine to make stud, track, furring channel, main channel (primary channel), carrying channel, wall angle, corner angle, edge bead, shadow line wall angle, top hat, clip, etc. Thickness is normally 0.4-0.6mm or up to 1.2mm. Raw material could be: cold-rolled steel, Galvanized steel, PPGI, high-tensile steel.

In Drywall system and drywall partition system, we could provide roll forming machine as following:

1. Metal Stud Roll Forming Machine

2. Metal track

Roll Forming Machine

3. Conner bead (Angle Bead / Wall Angle)

Roll Forming Machine

4.Metal Furring Channel Roll Forming Machine

5. Main Channel (C / U)

Roll Forming Machine

In Construction Industries, we are able to manufacture more machines like purlin roll forming machine, drywall roll forming machine, stud&track roll forming machine, metal deck(floor deck) roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc.

We could make roll forming machine with flying cut system to make working speed faster around 40m/min. And according to your drawing, we offer you double-row roll forming machine or triple-row roll forming machine that you could make two or three profiles in one machine, it reduces your machine cost and make it more affordable.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your all requirements. Whichever line you choose, the quality of SUNWAY Machinery will ensure you obtain perfectly functional profiles.

Profile Drawings

Production Line

Product Details

Manual Decoiler

Hydraulic Decoiler

Leveller Unit

Feeding Unit

Hydraulic

Punching Unit

Post

Cutter

Roll Forming System

Product Paramenters

|

Light Gauge Steel Roll Forming Machine

|

|

|

||

|

Machinable Material

|

A) Galvanized Coil

|

Thickness(MM):0.4-0.6mm, sometimes up to 1.2mm or as per your requirements

|

||

|

|

B) PPGI

|

|

||

|

|

C) Carbon steel Coil

|

|

||

|

Yield Strength

|

250 - 550 Mpa

|

|

||

|

Tensil Stress

|

350 Mpa-550 Mpa

|

|

||

|

Nominal Forming Speed

|

10-40(M/MIN)

|

|

||

|

Forming Station

|

8-14

|

* According To Your Profile Drawings

|

||

|

Decoiler

|

Manual Decoiler

|

* Hydraulic Decoiler (Optional)

|

||

|

Punching System

|

Hydraulic Punching

|

* Punching Press (Optional)

|

||

|

Main Machine Motor Brand

|

Sino-Germany Brand

|

* Siemens (Optional)

|

||

|

Driving System

|

Chain Drive

|

* Gearbox Drive (Optional)

|

||

|

Machine Structure

|

Wall Panel Station

|

* Forged Iron Station (Optional)

|

||

|

Rollers’ Material

|

Steel #45

|

* GCr 15(Optional)

|

||

|

Cutting System

|

Post-cutting

|

* Flying Servo Cutting (Optional)

|

||

|

Frequency Changer Brand

|

Delta

|

* Siemens (Optional)

|

||

|

PLC Brand

|

Delta

|

* Siemens (Optional)

|

||

|

Power Supply

|

380V 50Hz

|

* Or According To Your Requirment

|

||

|

Machine Color

|

Industrial Blue

|

* Or According To Your Requirment

|

||

Application

HOW DOES SUNWAY MACHINERY MAKE INSTALLATION DURING COVID-19?

The

installation of roll forming machine online during COVID-19 is for free!

Hereby SUNWAY will explain how we do the installation of our roll forming machine.

Third, when you receive the equipment, we will build a whatsapp or wechat group, our boss, engineer who design the machine, technician who assembly and calibrate machine and sales all will be in the group to support you in any doubt.

Fourth, we send you a manual in English so that you understand all the meanings of the buttons and how to start the machine.

Finally, SUNWAY has professional oversea engineer who can go to your place to install the machine and train your workers

especially in Middle East and Africa. The engineer can speak English, Arabic.

SUNWAY offers the best quality and the best service for our clients, especially in this situation. You don’t have to wait until

the COVID pass. You can produce the profiles right away with our machines.

First, we adjust the machine in our plant, we will ask which size you are going to produce first, we put the machine in the size it is going to produce and adjust all the correct parameters before the shipment, so you do not need to change anything when you got this machine.

Second, when we disassemble the machine for debug, we take videos so that you know how to connect them. It will show how to connect the cables and tubes, put the oils, put together the physical structures etc.

Third, when you receive the equipment, we will build a whatsapp or wechat group, our boss, engineer who design the machine, technician who assembly and calibrate machine and sales all will be in the group to support you in any doubt.

Fourth, we send you a manual in English so that you understand all the meanings of the buttons and how to start the machine.

Finally, SUNWAY has professional oversea engineer who can go to your place to install the machine and train your workers

especially in Middle East and Africa. The engineer can speak English, Arabic.

We have had many successes installing more complex machines in the years since COVID-19. For example

1) CZ automatic exchangeable roll forming machine installed successfully in UAE, Senegal, Cango

2) Roofing sheet roll forming machine installed successfully in Qatar, Bangladesh, Philippines, Turkey, UAE, etc.

3) PU sandwich panel production line installed successfully in Qatar

4) Slitting line installed successfully in Paraguay

5) Cut to length line installed successfully in Turkey.

SUNWAY offers the best quality and the best service for our clients, especially in this situation. You don’t have to wait until

the COVID pass. You can produce the profiles right away with our machines.

Hot Searches