- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

THD

-

Voltage:

-

110/220VAC

-

Power:

-

9.4Kw/h

-

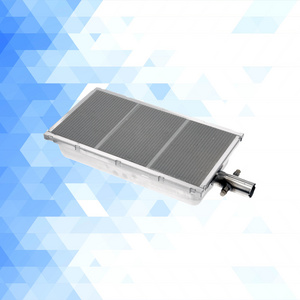

Dimension(L*W*H):

-

840*130*175mm

-

Weight (KG):

-

5

-

Heating mode:

-

Infrared Radiant Heating

-

Usage:

-

Powder coating, paint, food baking, nut drying

-

Main Material:

-

gray cast iron body,honeycomb ceramic with rare-earth catalyst

-

Nozzle:

-

brass

-

Fuel:

-

NG,LPG

-

Conversion rate:

-

above 95%

-

Advantage:

-

Infrared flameless, smokeless, 10~50% energy-saving

Quick Details

-

Machine Type:

-

heater, Drying Oven, Curing oven

-

Core Components:

-

heater

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

THD

-

Voltage:

-

110/220VAC

-

Power:

-

9.4Kw/h

-

Dimension(L*W*H):

-

840*130*175mm

-

Weight (KG):

-

5

-

Heating mode:

-

Infrared Radiant Heating

-

Usage:

-

Powder coating, paint, food baking, nut drying

-

Main Material:

-

gray cast iron body,honeycomb ceramic with rare-earth catalyst

-

Nozzle:

-

brass

-

Fuel:

-

NG,LPG

-

Conversion rate:

-

above 95%

-

Advantage:

-

Infrared flameless, smokeless, 10~50% energy-saving

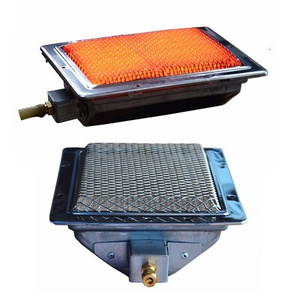

Why do you choose Catalytic Industrial infrared burner???

1. Save above 20% energy than common gas heaters

2. Zero harmful emmision

3. Pre-mixed, naturally aspirted burner, no need of air blower, air fan or fire chamber

4. Installed in all direction of an oven

5. Completed thermostat controlling system!

Now we have following sizes for different sizes oven:

|

MODEL |

Dimension |

Weight |

GasType |

Heat Output |

Consumption |

||

|

mm |

kg |

KW/h |

Kcal/hr |

NG(m3/h) |

LPG(kg/h) |

||

|

HD61 |

423*80*94 |

3.8 |

NG/LPG |

2.4 |

2030 |

0.18 |

0.18 |

|

HD82 |

219*164*108 |

4.8 |

NG/LPG |

3.1 |

2700 |

0.24 |

0.24 |

|

HD101 |

690*80*115 |

6.9 |

NG/LPG |

3.9 |

3380 |

0.3 |

0.29 |

|

HD162 |

570*130*175 |

8 |

NG/LPG |

6.3 |

5400 |

0.49 |

0.47 |

|

HD242 |

840*130*175 |

11.7 |

NG/LPG |

9.4 |

8120 |

0.75 |

0.71 |

|

HD262 |

930*130*175 |

13 |

NG/LPG |

10.9 |

9360 |

0.8 |

0.82 |

Powder Coating Oven Gas Burne r Material :

1. Shell: Cast Iron

2. Radiant part: cordierite honeycomb plates with black processed rare-earth catalyst coated

3. Nozzle: brass

4. Up cover: stamped stainless iron

Industrial Oven Gas Burner Advantages :

1.Save above 30% energy than electric

2.High efficient: preheating up time can be reduced to under 30min

3.Eco-friendly : CO<80ppm;NOx<10ppm;CHx<50ppm

4.Naturally aspirated burner,no need of accessories equipment,like air blower,fire chamber...

Industrial Oven Gas Burne r Applied Range

1. Food Industry: Rice Biscuit( rice cookies covered with snow-like sugar )assembly line, grilled chicken, biscuit, egg roll, roasting shredded squid oven, oven for roast duck, smokeless oven, griddle, middle eastern oven, hot pot oven, roasting pachyrhizus oven, snack car, soup oven, cooking assembly line, infra-red gas baking pan, deep-fry assembly line, water-removing machine, baking, etc.

2. Painting Industry: Liquefied or powered painting assembly line, warm-up, preliminary treatment of heating, desiccating wood, galvanization drying assembly line, phosphatization drying assembly line

Fiber industry: Carpet latex dryer, dyeing dryer, printing dryer, textile dryer, industrial clothes dryer, latex gloves drying assembly line

3. Glass and ceramics industry: Enamel firing dryer, glass oven, heat-setting machine, mould drying, fritting, parching

4. Paper industry: All kinds of paper dry lines and auxiliary drying heat wall

5. Farming and animal husbandry: Heating of barton, heating of crops, grain dryer.

Usage of technical parameters

Table 1:The use of technical parameters

|

Items |

Technical parameters |

|

Types |

natural gas (NG),liquefied petroleum gas (LPG) |

|

Light-off temperature |

≥350 |

|

complete combustion temperature |

≤380 |

|

Heat source temperature |

around 850 |

|

Baking temperature range |

30---850 |

|

Wavelength range |

1.9μm--15μm |

|

Furnance pressure natural |

2000pa(NG)/2800pa(LPG) |

Table 2: Comparison table for all kinds of energy consumption

|

Furnace type Parameters |

Electronic

|

Oil furnace |

Coal-fired furnace |

Infrared catalytic heaters |

|

Energy requirement

|

10,000Kcal |

10,000Kcal |

10,000Kcal |

10,000Kcal |

|

Temperature |

180 |

180 |

180 |

180 |

|

Energy consumption |

Electricity(15 kW/h)

|

Electricity (1Kw/h)+ diesel (2Kg) |

Coal (10Kg)

|

LPG(0.9Kg) |

|

Heating time |

20 minutes |

40 minutes |

90 minutes |

5-8 minutes |

Applications photos for reference:

This burner is naturally aspirated type, no need of air blower, fan or fire chamber.They are usually installed directly into an oven bottom, two side or upside down are also ok. Only need to bear the air hole on burner back into airs.

Industrial Oven System Gas Burner Application photos:

We can supply a whole infrared burner system , includes a electric thermostat controller, presure gauge, pressure regulator.

Any question or need,just feel free to send us inquiry.