- Product Details

- {{item.text}}

Quick Details

-

Name:

-

Chalk making machine

-

Automatic grade:

-

automatic

-

Capacity:

-

4000-8000 pcs/ h

-

Mold size:

-

800 pieces/per mold

-

MOQ:

-

1 pieces

-

Chalk size:

-

10 mm*8 mm* 75 mm

-

Package:

-

660*480*360(L*W*H)

-

Weight:

-

65kg

-

Country of origin:

-

China

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

65

-

Model:

-

HSC-800-1

-

Name:

-

Chalk making machine

-

Automatic grade:

-

automatic

-

Capacity:

-

4000-8000 pcs/ h

-

Mold size:

-

800 pieces/per mold

-

MOQ:

-

1 pieces

-

Chalk size:

-

10 mm*8 mm* 75 mm

-

Package:

-

660*480*360(L*W*H)

-

Weight:

-

65kg

-

Country of origin:

-

China

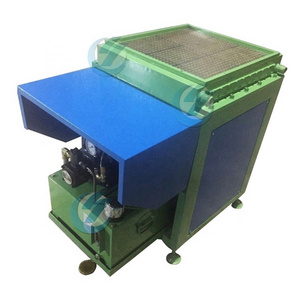

Low price sale chalk making machine school b lackboard c halk p iece m oulding

The

HSC

-800 series chalk machine is the most advanced manufacturing production equipment of high quality at home.

One mould , manual mixing , one worker .

One worker can operate 3 sets,package need 1 person.

Specifications:

Model:

HSC

-800

-1

Capacity: 4000-8000 pcs/ h

Mold size: 800 pieces/per mold

Chalk size: 10 mm*8 mm* 75 mm

Package size: 660*480*360(L*W*H)

Weight: 65kg

1.

F

ree of dust

2.

G

reat treatment ability

3.

W

earable- resistant and longevity/durable

Chalk production process

1. Mold evenly brush oil, brush back and forth with a wide brush, brush the new mold should be more oil.

2. The mold plate moving up and down a few times, the screw top and the bottom plate comes into contact.

3. Turn on the water, turn on the water with a movable foot switch pedal to pedal in the end, until the water in the water last.(First mold first feed, add water)

4. Addition, the quantitative good gypsum powder into the mixing bucket.

5. Mixing, stirring for 10-20 seconds to start the motor.

6. Put the pulp, put a good brush oil stirred to die bottom of the barrel, hit the switch to open the pulp slurry was stirred well into the mold until the stream last.

7. Calibrating with a plastic scraper to scrape the pulp mold hole, scrape out the remaining pulp mold mouth gelling.

8. A mold, a new mold die not too late. Chalk can feel a little hard to top 2-5 mm, 1 to 2 minutes over again ejection

|

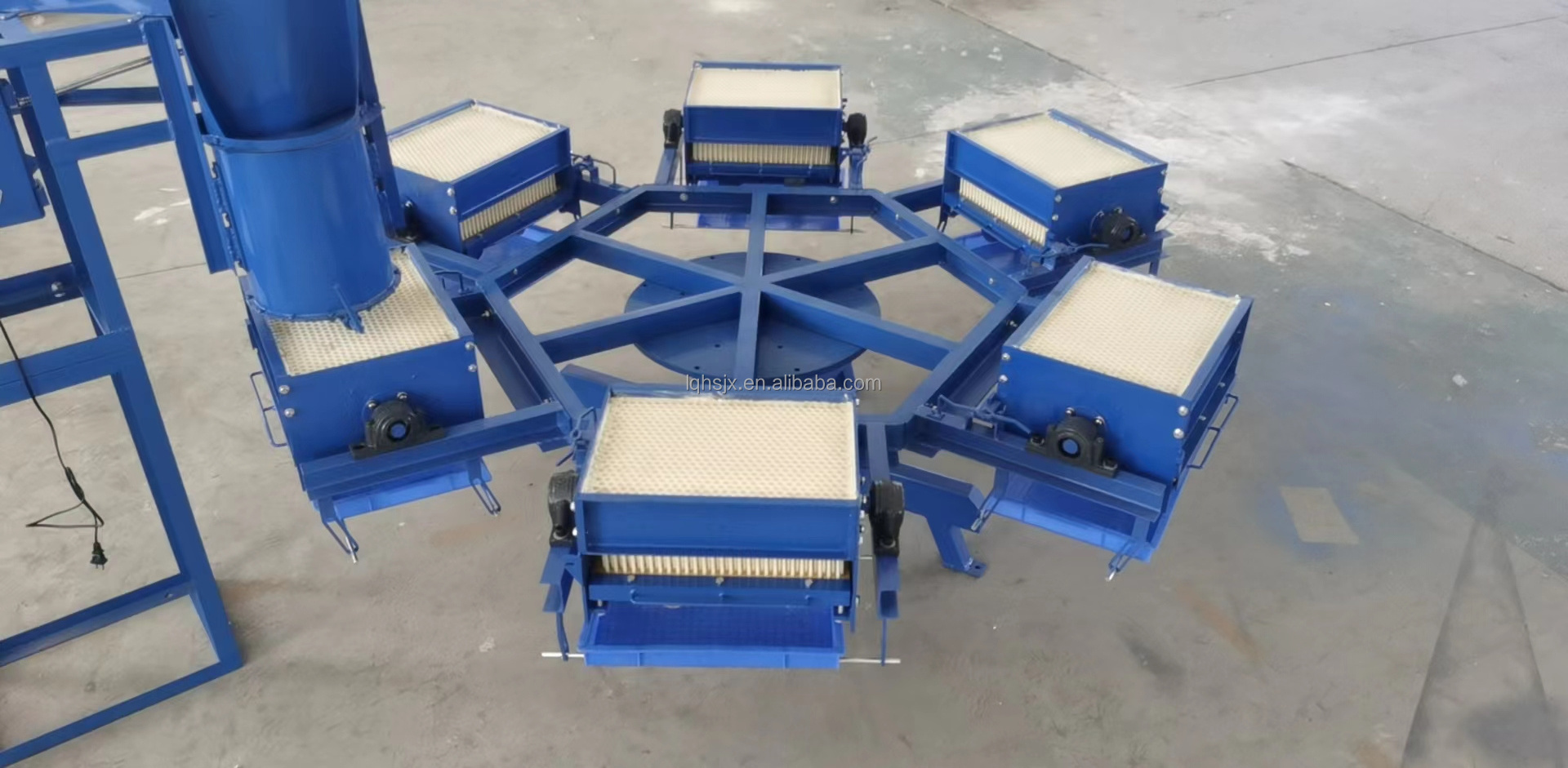

Model No. |

Capacity(pcs/h) |

Mold Specification (pcs/ mold) |

Chalk size |

Molds quantity |

|

HSC800-1 |

4000-8000 |

800 |

10mm*8mm*80mm |

1 PC |

|

HSC800-2 |

8000-12000 |

800 |

10mm*8mm*80mm |

2 PCS |

|

HSC800-4 |

12000-24000 |

800 |

10mm*8mm*80mm |

4 PCS |

|

HSC800-6 |

24000-32000 |

800 |

10mm*8mm*80mm |

6 PCS |

|

HSC800-8 |

32000-48000 |

800 |

10mm*8mm*80mm |

8 PCS |

Packing: wooden case of international standard.

Delivery date: 15 days after receive the deposit

After-sale services:

1.one-year warranty for parts ,and provide the technical support forever.

2 .According to the requests of the consumers, the use and other aspects of technical guidance.

3.To ensure the supply of repair parts.

4. Responsible for the repair service.

5. On the product of "Three Guarantees".

Why choose us:

1.We are the screen printing machine manufacturer for more than 20 years experience.

2. screen printing machine CE certified

3. Experienced international sales team, skilled in international business for many years.