- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Miharting

-

Dimension(L*W*H):

-

350*158*240cm

-

Weight (KG):

-

8500

-

Bending width:

-

3000mm

-

Product name:

-

Sheet metal brake Bender

-

Keyword:

-

Brake Press Machine

-

Application:

-

Stainless Plate Bending

-

Name:

-

pneumatic Bending Machine

-

Material:

-

Sheet Metal

-

Usage:

-

Metal Sheet Folding

-

Operation:

-

Easy-auto

-

Function:

-

metal working machinery

-

Folding Materials:

-

Carbon Steel

Quick Details

-

Bending Thickness(mm):

-

0.3 - 1.5 mm

-

Bending Length(mm):

-

1500 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Miharting

-

Dimension(L*W*H):

-

350*158*240cm

-

Weight (KG):

-

8500

-

Bending width:

-

3000mm

-

Product name:

-

Sheet metal brake Bender

-

Keyword:

-

Brake Press Machine

-

Application:

-

Stainless Plate Bending

-

Name:

-

pneumatic Bending Machine

-

Material:

-

Sheet Metal

-

Usage:

-

Metal Sheet Folding

-

Operation:

-

Easy-auto

-

Function:

-

metal working machinery

-

Folding Materials:

-

Carbon Steel

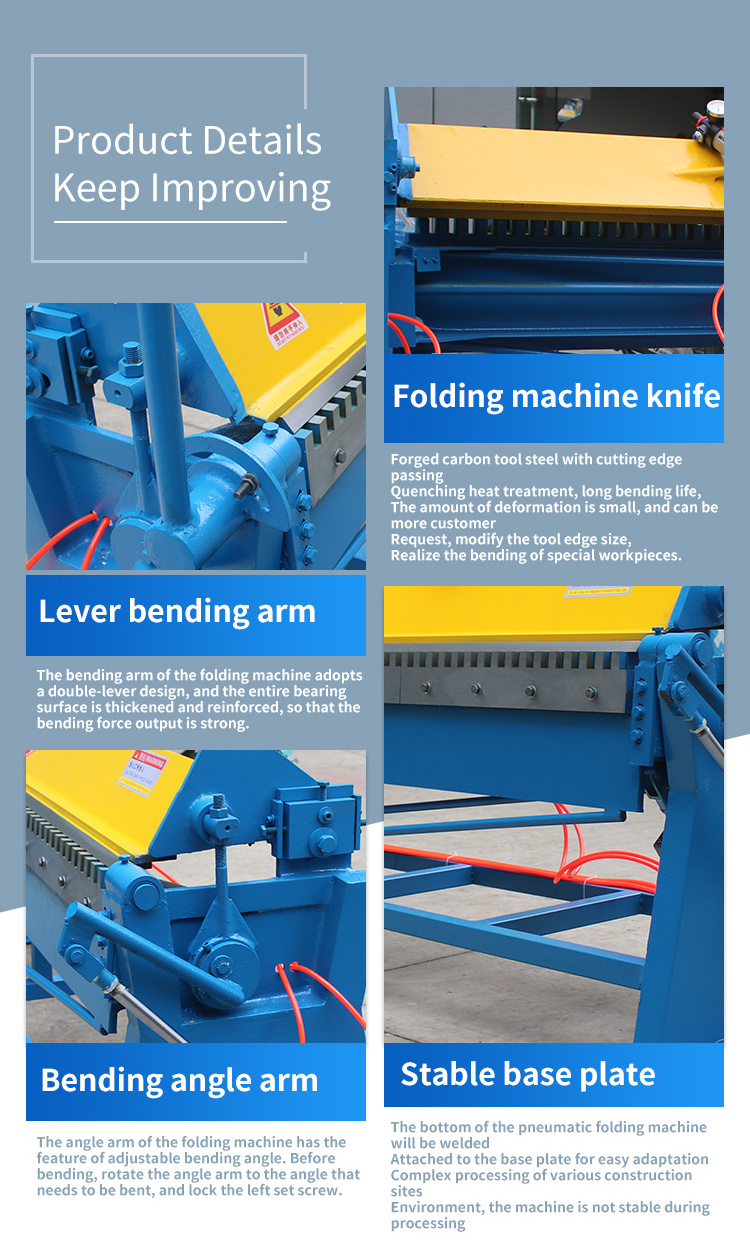

Product Description

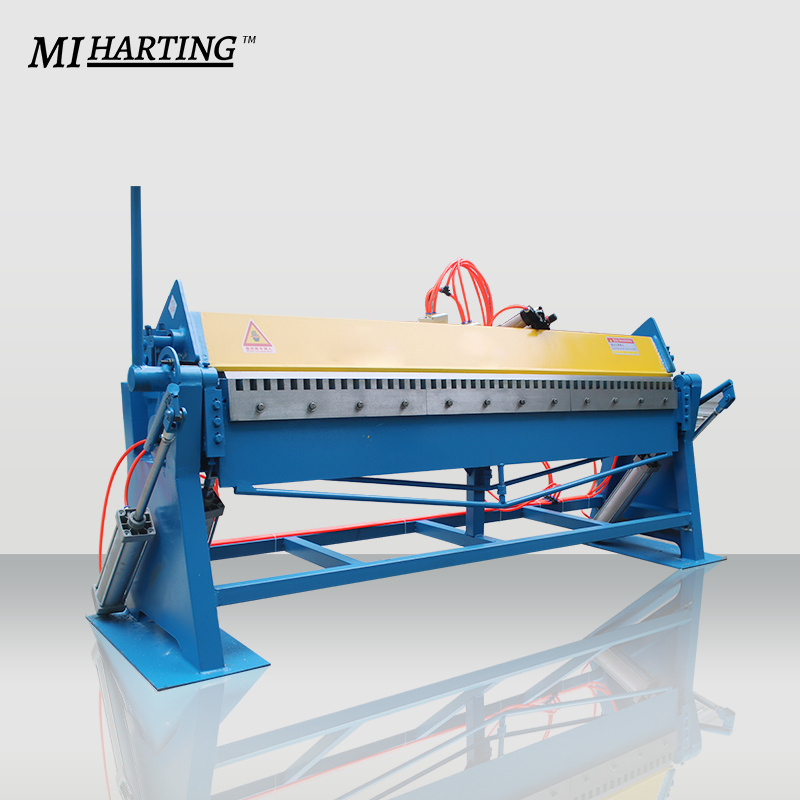

1.5*3000 Heavy Duty Pneumatic Sheet Metal Brake Pan And Box Folder Upper Folding bending Machine

A press brake is a machine tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by

clamping the workpiece between a matching punch and die.

clamping the workpiece between a matching punch and die.

the stroke length, the distance between the frame uprights or side housings, back gauge distance, and work height.

1. Heavy duty steel fabricated frame provides accurate bends

2. Extended fingers allows bending of pans or boxes to a depth of 200mm

3. Machine equipped with a graduation ruler on both sides, readout eliminates the bend angle guess work

4. Ground segmented fingers can be repositioned to suit many applications

5. Safety top beam support stop lever located on right side of machine

6. Quick action beam adjustment for varying material thickness

7. Includes rear manual back gauge

2. Extended fingers allows bending of pans or boxes to a depth of 200mm

3. Machine equipped with a graduation ruler on both sides, readout eliminates the bend angle guess work

4. Ground segmented fingers can be repositioned to suit many applications

5. Safety top beam support stop lever located on right side of machine

6. Quick action beam adjustment for varying material thickness

7. Includes rear manual back gauge

1.5*3000 Heavy Duty Pneumatic Sheet Metal Brake Pan And Box Folder Upper Folding bending Machine

|

Model

|

Min.folding angle(°)

|

Max.Plate thickness (mm)

|

Max.Plate width (mm)

|

Rated air pressure (Mpa)

|

Open distance (mm)

|

Weight (kg)

|

|

QS-1.5*1000

|

80

|

1.5

|

1000

|

0.6

|

60

|

320

|

|

QS-1.5*1300

|

80

|

1.5

|

1300

|

0.6

|

60

|

360

|

|

QS-1.5*1500

|

80

|

1.5

|

1500

|

0.6

|

60

|

380

|

|

QS-1.0*2000

|

80

|

1.0

|

2000

|

0.6

|

60

|

460

|

|

QS-1.0*3000

|

80

|

1.0

|

3000

|

0.6

|

60

|

750

|

|

QS-0.8*2500

|

80

|

0.8

|

2500

|

0.6

|

60

|

560

|

Hot Searches