- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Boqiao, Boqiao

-

Model Number:

-

YH9818AB, YH9818AB

-

Type:

-

Two Component, Two Component

-

Product name:

-

Potting Glue For Electronic

-

Keywords:

-

electronic potting glue

-

Viscosity:

-

40000-45000

-

Advantage:

-

Suitable High Temperate Climates

-

MOQ:

-

1 KG

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

Quick Details

-

CAS No.:

-

67763-03-05

-

Other Names:

-

epoxy resin and hardener

-

MF:

-

mSiO2 nH2O

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Boqiao, Boqiao

-

Model Number:

-

YH9818AB, YH9818AB

-

Type:

-

Two Component, Two Component

-

Product name:

-

Potting Glue For Electronic

-

Keywords:

-

electronic potting glue

-

Viscosity:

-

40000-45000

-

Advantage:

-

Suitable High Temperate Climates

-

MOQ:

-

1 KG

-

Material:

-

Pure Epoxy

-

Packing:

-

Bottle

BEFORE YOU BUY

NOTE!!!!!!

Before you place order, please contact me to confirm shipping cost!

Product Description

Epoxy Resin - Heat Resistance

UL certificate No. -E513688

YH-9818 Epoxy is a chemical liquid that cures under normal and low temperature conditions. It has good leveling, natural defoaming, low viscosity, high hardness and high strength. It can be cured at room temperature or by heating. Dedicated in transformers, sensors, buzzers, atomizers, negative ion generators, aquarium water pumps, ignition coils, power modules, electronic controllers and other electronic components

CHARACTERISTICS

1. It can be cured at normal temperature, heating can fast curing.

2. stable high hardness , can be tough as stone.

Good performance in fire resistance. Approved by UL, and meet 94V0 grade

3. Good performance in moisture-proof, water-proof, oil-proof and dust-proof, and durable

4. Compression resistance and high adhesive strength

5. Effectively against environmental pollution.

6. No bubbles, smooth surface. Good fluidity, easy to flow into the gap

2. stable high hardness , can be tough as stone.

Good performance in fire resistance. Approved by UL, and meet 94V0 grade

3. Good performance in moisture-proof, water-proof, oil-proof and dust-proof, and durable

4. Compression resistance and high adhesive strength

5. Effectively against environmental pollution.

6. No bubbles, smooth surface. Good fluidity, easy to flow into the gap

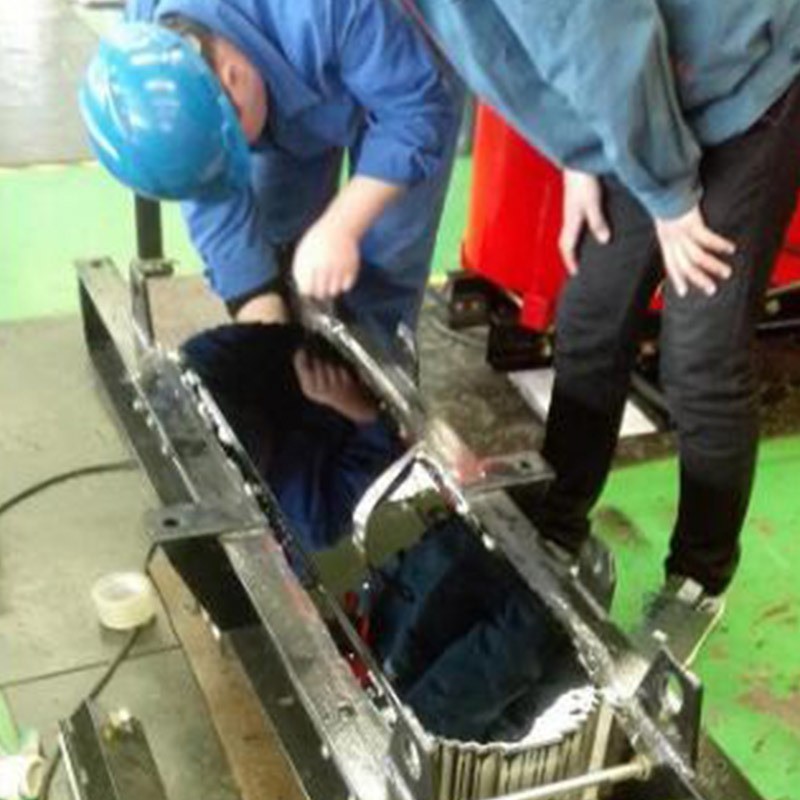

APPLICATION

transformers, sensors, buzzers, atomizers, negative ion generators, aquarium water pumps, ignition coils, power modules, electronic controllers and other electronic components. Specially recommended for electrical parts that has a good property in

TECHNICAL DATA

|

Item

|

Units/conditions

|

YH-9008A

|

YH-9008A

|

|

|

Before Mixing

|

Transparent

|

Black, or gray liquid

|

transparent liquid

|

|

|

Viscosity 60℃

|

15000~17000

|

20~100

|

||

|

Density(g/cm3)

|

1.75~1.85

|

1.08~1.15

|

||

|

Ratio

|

By weight

|

10

|

1

|

|

|

Pot life

|

Mins / at 25 ℃

|

30-40min (800g)

|

||

|

curing time

|

Initial curing time at 25 ℃

|

3-4 hrs

|

||

|

Fully curing time at 25 ℃

|

24 hrs

|

|||

|

Curing time at 60~80℃

|

3-4 mins

|

|||

|

After curing

|

Hardness (25℃)

|

82-88shore-D

|

||

|

Surface resistivity

|

>1.2×10

14

Ω.cm

|

|||

|

Volume resistivity(25℃)

|

>1.4×10

15

Ω.cm

|

|||

|

Voltage resistivity

|

>27 Kv/mm

|

|||

|

Dielectric constant

|

4.80-5.30 ( 50Hz)

|

|||

|

Dielectric loss

|

0.03-0.05 Tδ

|

|||

|

Tensile Strength

|

55-70 MPa

|

|||

|

Bending strength

|

95-110 MPa

|

|||

|

Thermal conductivity

|

0.8-1.0W/(m.k)

|

|||

|

Temperature resistant

|

-60℃ to 155℃

|

|||

Note: The above performance data is based on the 24 hours complete curing test at room temperature, just for customers' reference only, and cannot guarantee that all the above values can be reached in a specific environment. Please refer to the actual measured data when conducting.

Operative Steps

1. Weighing: In order to achieve the best performance of the product, it is recommended to use high-precision electronic weighing for accurate weighing.

2. Mixing: Mix the weighed materials A and B and stir evenly; make sure the resin on the walls and bottom of the container is fully dispersed if you mix by hand.

3. Infusion: Inject the mixed materials A and B into the objects to be infused, and cure at room temperature or medium temperature.

4. The more mixed amount, the less curing time, and may release of a lot of heat, so please pay attention to control amount, and the mixed liquid should be used up as soon as possible in case of curing in the container.

5. Before using it in large quantities, please try it in small quantities for test.

6. After injection, the glue will gradually penetrate into the gaps of the product. If necessary, please perform the second injection;

7. When it curing, please keep the room clean to prevent impurities or dust from falling onto the surface of the uncured liquid.

2. Mixing: Mix the weighed materials A and B and stir evenly; make sure the resin on the walls and bottom of the container is fully dispersed if you mix by hand.

3. Infusion: Inject the mixed materials A and B into the objects to be infused, and cure at room temperature or medium temperature.

4. The more mixed amount, the less curing time, and may release of a lot of heat, so please pay attention to control amount, and the mixed liquid should be used up as soon as possible in case of curing in the container.

5. Before using it in large quantities, please try it in small quantities for test.

6. After injection, the glue will gradually penetrate into the gaps of the product. If necessary, please perform the second injection;

7. When it curing, please keep the room clean to prevent impurities or dust from falling onto the surface of the uncured liquid.

Emergency measures

If Inhale: Rinse with water and seek medical support.

If touching skin: If it causes any allergies by skin contact, soak in dilute acetic acid solution for 10-20 minutes and go to the

hospital as soon as possible.

If touching eyes: Rinse with water immediately and go to the hospital as soon as possible.

Contaminated clothing should be changed immediately.

If touching skin: If it causes any allergies by skin contact, soak in dilute acetic acid solution for 10-20 minutes and go to the

hospital as soon as possible.

If touching eyes: Rinse with water immediately and go to the hospital as soon as possible.

Contaminated clothing should be changed immediately.

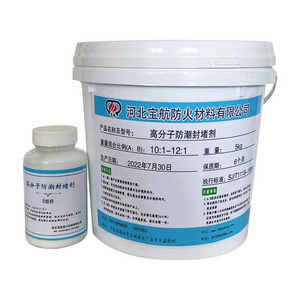

storage & packing

|

Part A

|

Part B

|

Other (can be customized)

|

|

5KG/20kg Bucket

|

5KG/bucket

|

1kg/2kg/5kg/20kg

|

The product should be stored and sealed in a cool and ventilated environment at 25 ° C; the hardener is relatively sensitive to moisture in the air and should be sealed in time when not used up.

FAQ

1. Are you trading company or factory?

Obviously we are a factory. We own 5000sqm factory and advanced facilities, with 30 tons daily output. Our factory is in Foshan city which is next to Guangzhou.

2. Is the resin good quality?

Sure. It' s super gross, high crystal, high hardness, bubble free, UV resistance, and Scratch proof.

3. What’s the maximum casting thickness for river table?

It depends on the temperature, mixing quantity, and size of the holeNormally, 5-7cm available in 25 25C

4. Do you provide free sample before bulk order?

Yes, 1-2kg free sample available. you may need to bear the freight for samples , when you make bulk order to us we will reduce from the total amount.

5. Which shipping way is available?

We welcome if you have your own shipping forwarder in China. If not, we can ship via our agent. Fedex will be the first choice less than 20kg.

6. What’s your MOQ?

It depends on the shipping. Sample order have no MOQ, ship by sea will be 200kg MOQ

7. Which payment way is workable?

Trade Assurance on Alibaba, Western Union, L/C, Paypel, T/T (50%deposit, 50% before shipment after presentation of ready cargo)

8. Delivery time?

Normally,delivery time of standard order is 1-3 days after you pay.Customized order will need 15 20 days.

9. How to be your distributor?

A:We welcome distributors and agents worldwide,we will provide the best solution and service for our partners.

10. What’s the storage date

Normally 12 Month available if well sealed. After 12 months, it can still be used but there will be a light yellowish, and may not be cured as well as before.

Hot Searches