Single-Column Hydraulic Press Machine adopted Japanese technology wet clutch, featuring stable working performance, high

production efficiency, low noise, and less maintenance cost. Equipped with Japan SHOWA hydraulic overload protection pump ensuring

longer service life. It's the most practical and mature small-size press machine in the stamping field in recent years. Highly

recommended for the production of metal pieces

·We have designed the Single-Column Hydraulic Press with different power ranges, from 25 to 400 tonnes.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

fengli

-

Weight (T):

-

0.24 T

-

Motor Power (kw):

-

3 kw

-

Marketing Type:

-

New Product 2023

Quick Details

-

Machine Type:

-

Single Column Hydraulic Press

-

Return Force (kN):

-

3 kN

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

fengli

-

Weight (T):

-

0.24 T

-

Motor Power (kw):

-

3 kw

-

Marketing Type:

-

New Product 2023

Product Introduction

Hycules Single-Column Hydraulic Press Machine

Details Images

Applications

Auto parts: automobile body covering parts, braking, fuel tanks, chassis, axle case, bumper

Household appliances: washing machine, Tv, refrigerator, air conditioning, rice cooker, and other parts

Kitchenware: sink, tea set, and Other kinds of containers.

Household appliances: washing machine, Tv, refrigerator, air conditioning, rice cooker, and other parts

Kitchenware: sink, tea set, and Other kinds of containers.

Features

·Steel welded body, tempering treatment or VSR(Vibratory Stress Relief), high rigidity, accuracy and stability.

·Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact.

·The crankshaft undergoes grinding treatment after high-frequency quenching.

·Lengthened six-face rectangle guide with a surface of bronze plate.

·Vertical located crankshaft, compact structure.

·PLC control and imported safety duplex valve.

·Wet type combined multi discs friction clutch and brake.

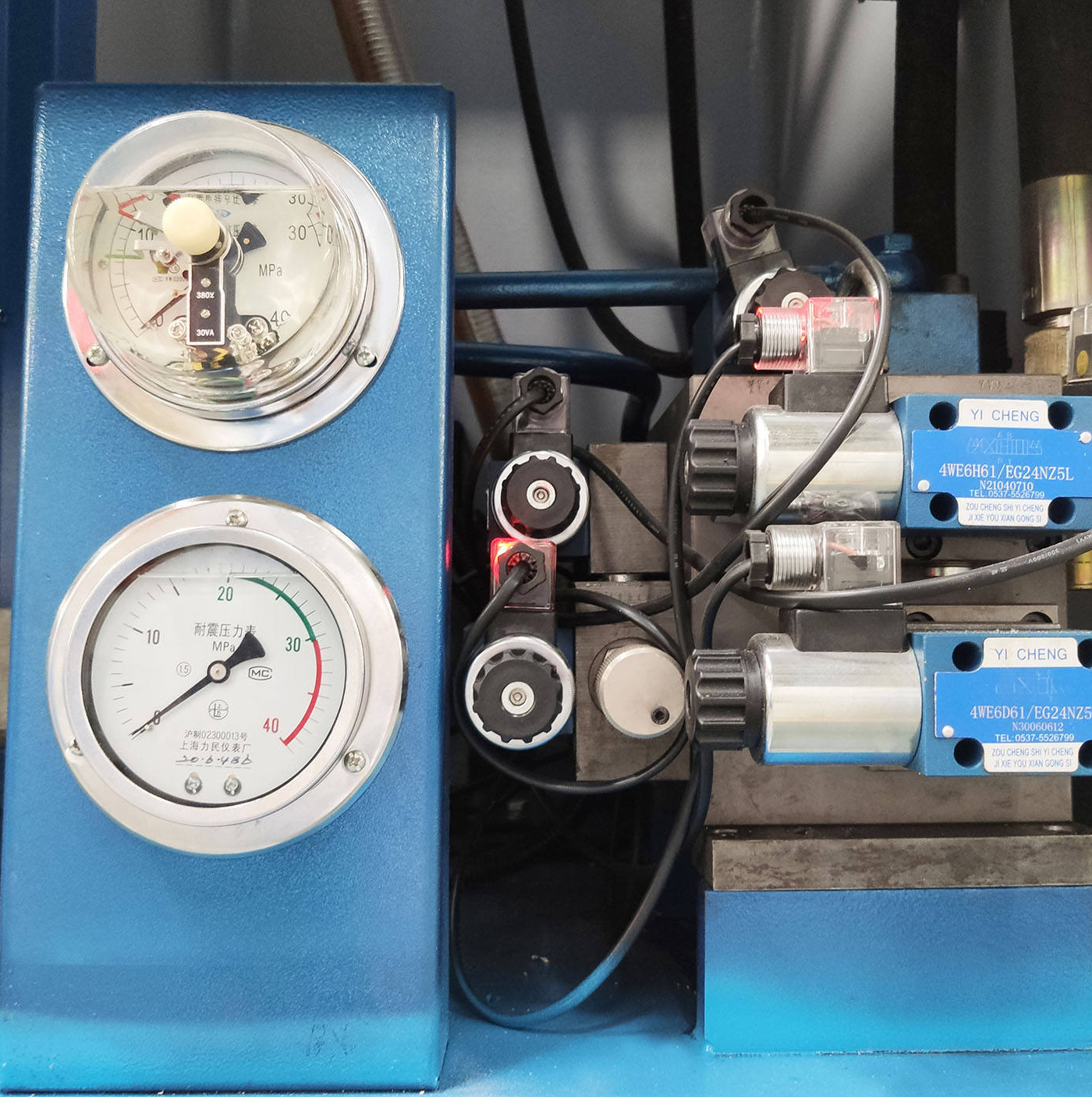

·Hydraulic overload protected.

·Pneumatic dual balance cylinders, which balance the slide and punch weight to reduce noise and impact.

·The crankshaft undergoes grinding treatment after high-frequency quenching.

·Lengthened six-face rectangle guide with a surface of bronze plate.

·Vertical located crankshaft, compact structure.

·PLC control and imported safety duplex valve.

·Wet type combined multi discs friction clutch and brake.

·Hydraulic overload protected.

Electric Installation And Safety

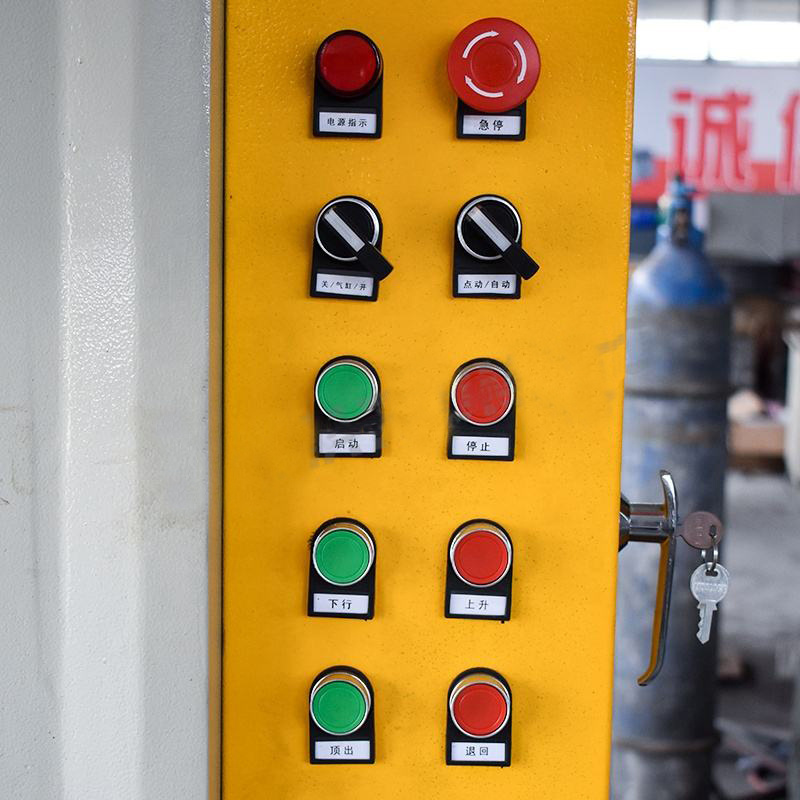

The control panel features a switch enabling the user to select the desired type of work in a manual, semi-automatic, or automatic

position and a switch to select either the fast speed or slow speed.

Electrical and hydraulic maneuvers are redundant and self-controlled.

They incorporate an additional safety block and self-control devices for maneuver and safety.

It includes the verification and certification of the correct operation and the safety distance for the photocells.

position and a switch to select either the fast speed or slow speed.

Electrical and hydraulic maneuvers are redundant and self-controlled.

They incorporate an additional safety block and self-control devices for maneuver and safety.

It includes the verification and certification of the correct operation and the safety distance for the photocells.

Product Paramenters

Delivery/Package

Factory View

FAQ

|

|

|

|

|

|

||||

Hot Searches