- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

40

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 3 mm

-

Heating Power (kW):

-

68 kW

-

Air Comsumption(L/min):

-

200 L/min

-

Water Comsumption(L/min):

-

100 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUGONG MACHINERY

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

5400*1800*1900

-

Weight (T):

-

3.2 T

-

Power(KW):

-

24

-

Product name:

-

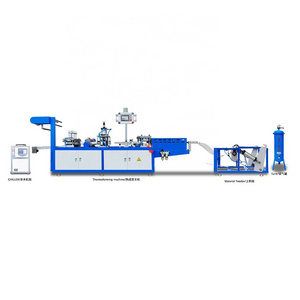

Automatic Plastic Thermoforming Machine

-

Application:

-

Plastic Products

-

Production speed:

-

15-40moulds per min

-

Raw material:

-

PP PET PVC

-

Mould cooling water:

-

Recycled water

-

Max plasic sheet width:

-

500mm

-

Max forming area:

-

450*260mm

-

Max forming depth:

-

50mm

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Max.Forming Height(mm):

-

130 mm

-

Forming Width (mm):

-

700 mm

-

Forming Length (mm):

-

710 mm

-

Production Speed(Cycles/min):

-

40

-

Air Pressure(MPa):

-

0.7 MPa

-

Sheet Thickness(mm):

-

0.15 - 3 mm

-

Heating Power (kW):

-

68 kW

-

Air Comsumption(L/min):

-

200 L/min

-

Water Comsumption(L/min):

-

100 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YUGONG MACHINERY

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

5400*1800*1900

-

Weight (T):

-

3.2 T

-

Power(KW):

-

24

-

Product name:

-

Automatic Plastic Thermoforming Machine

-

Application:

-

Plastic Products

-

Production speed:

-

15-40moulds per min

-

Raw material:

-

PP PET PVC

-

Mould cooling water:

-

Recycled water

-

Max plasic sheet width:

-

500mm

-

Max forming area:

-

450*260mm

-

Max forming depth:

-

50mm

-

Marketing Type:

-

Ordinary Product

Product Description

Thermoforming machine

is a special plastic processing method for

processing thermoplastic sheets into

various products . The sheet is clamped on the frame and heated to a softened state, and under the action

of external force, it is made close to the profile of the mold to obtain a shape similar to the profile. After

cooling and shaping, the finished product is finished. This process is also used in rubber processing.

New advances in thermoforming have been made in recent years, such as continuous production techniques

from extruded sheet to thermoforming.

various products . The sheet is clamped on the frame and heated to a softened state, and under the action

of external force, it is made close to the profile of the mold to obtain a shape similar to the profile. After

cooling and shaping, the finished product is finished. This process is also used in rubber processing.

New advances in thermoforming have been made in recent years, such as continuous production techniques

from extruded sheet to thermoforming.

There are only

3 methods of plastic thermoforming in thermoforming machines

, namely female moulding,

male moulding and pair moulding. The thermoforming machine should be able to repeat the thermoforming

production cycle according to a certain program to make exactly the same product. There are many types of

thermoforming machines, there are manual, semi-automatic and automatic thermoforming machines. Thermoforming

products are large in volume and small in quantity, so semi-automatic or manual thermoforming machines are suitable.

On the contrary, if the volume of the product is small and the quantity is large, it is more appropriate to use an

automatic thermoforming machine.

Widely application in thermoforming process , there are more and more thermoformed products on the market, such as cups, plates, food trays,

toys, helmets, as well as auto parts, architectural decorations, chemical equipment, etc.

male moulding and pair moulding. The thermoforming machine should be able to repeat the thermoforming

production cycle according to a certain program to make exactly the same product. There are many types of

thermoforming machines, there are manual, semi-automatic and automatic thermoforming machines. Thermoforming

products are large in volume and small in quantity, so semi-automatic or manual thermoforming machines are suitable.

On the contrary, if the volume of the product is small and the quantity is large, it is more appropriate to use an

automatic thermoforming machine.

Widely application in thermoforming process , there are more and more thermoformed products on the market, such as cups, plates, food trays,

toys, helmets, as well as auto parts, architectural decorations, chemical equipment, etc.

Specification

|

Model

|

YG-720

|

Sheet width range

|

500-780mm

|

|

|

|

Maximum forming area

|

320×720mm

|

Sheet thickness range

|

0.2-2.0mm

|

|

|

|

Maximum forming depth

|

120mm

|

Maximum roll diameter

|

800mm

|

|

|

|

Air pressure

|

0.7Mpa

|

Water consumption

|

100L/min (15-20ºC)

|

|

|

|

Air consumption

|

2000 liters/min

|

Maximum production speed

|

40 molds/min

|

|

|

|

Pressing motor

|

7.5KW (servo)

|

Heating motor power

|

68kw

|

|

|

|

Host motor power

|

4kw

|

Feeding motor power

|

5kw (servo)

|

|

|

|

Winding motor power

|

0.37kw

|

Finishing motor

|

2KW (servo)

|

|

|

About raw material, the plastics used for thermoforming

mainly include polystyrene, polyvinyl chloride, polyolefins

(such as polyethylene, polypropylene), polyacrylates (such as polymethyl methacrylate) and cellulose (such as nitrocellulose, Cellulose acetate, etc.) plastics, also used in engineering plastics (such as ABS resin, polycarbonate).

(such as polyethylene, polypropylene), polyacrylates (such as polymethyl methacrylate) and cellulose (such as nitrocellulose, Cellulose acetate, etc.) plastics, also used in engineering plastics (such as ABS resin, polycarbonate).

Thermoforming machine for plastics product main features:

1. The maximum speed of the machine in production can reach 3 seconds/mold, all of which use servo control system,

plus the overall advanced automation system, which can adapt to various sheets.

1. The maximum speed of the machine in production can reach 3 seconds/mold, all of which use servo control system,

plus the overall advanced automation system, which can adapt to various sheets.

2. The blister machine has the most user-friendly mold replacement structure, which greatly shortens the mold replacement time. The advanced heating system adopts intelligent module temperature control, fast response, short time, and strives for the highest benefit and low cost.

3. The new type of electric furnace, the heating frame of the upper and lower furnaces are all designed with stainless steel and heat insulation board materials, which are lightweight, low in cost, fast in heat dissipation, and simple in appearance.

4. The heater adopts Sino-British joint-venture ceramic infrared radiant heater and imported solid-state relay with non-contact output, which ensures fast heating, high precision, stability, and temperature control error of ±1°C.

5. The upper and lower molds are driven by servo motors, which makes it easier to control the speed of the upper and lower molds. The upper and lower molds are guided by a guide post with a diameter of 50mm, and the driving screw also uses a ball screw with a diameter of 50mm. Thereby, the upper and lower molds can move up and down more forcefully and smoothly.

6. Each servo motor is equipped with a thermal protection device to prevent the servo motor from being damaged due to overload and overcurrent due to long-term operation. Each motor is equipped with an overcurrent protection device.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Automatic High Production Blister Thermoforming Machine for Fruit PET Container

adopt to export standard wooden crate packing

Hot Searches