- Product Details

- {{item.text}}

Quick Details

-

Power:

-

46.5 kW

-

Dimension(L*W*H):

-

2.6(L) x 1.0(W) x 1.98(H)m

-

Weight (KG):

-

0

-

Wire diameter:

-

5-12mm

-

Cut-off Length:

-

800-12000mm (we could customize according to customer's requirements)

-

Pulling speed:

-

~150m/min

-

Length Adjustable Mode:

-

Manual/Automatic

-

Cut mode:

-

Servo Shear (flying shear)

-

Speed control:

-

Steepless Adjustable

-

Material:

-

steel bar or stainless steel bar

-

Tolerance:

-

±2mm

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

CABR/M

-

Voltage:

-

customize as customers' need

-

Power:

-

46.5 kW

-

Dimension(L*W*H):

-

2.6(L) x 1.0(W) x 1.98(H)m

-

Weight (KG):

-

0

-

Wire diameter:

-

5-12mm

-

Cut-off Length:

-

800-12000mm (we could customize according to customer's requirements)

-

Pulling speed:

-

~150m/min

-

Length Adjustable Mode:

-

Manual/Automatic

-

Cut mode:

-

Servo Shear (flying shear)

-

Speed control:

-

Steepless Adjustable

-

Material:

-

steel bar or stainless steel bar

-

Tolerance:

-

±2mm

Product Overview

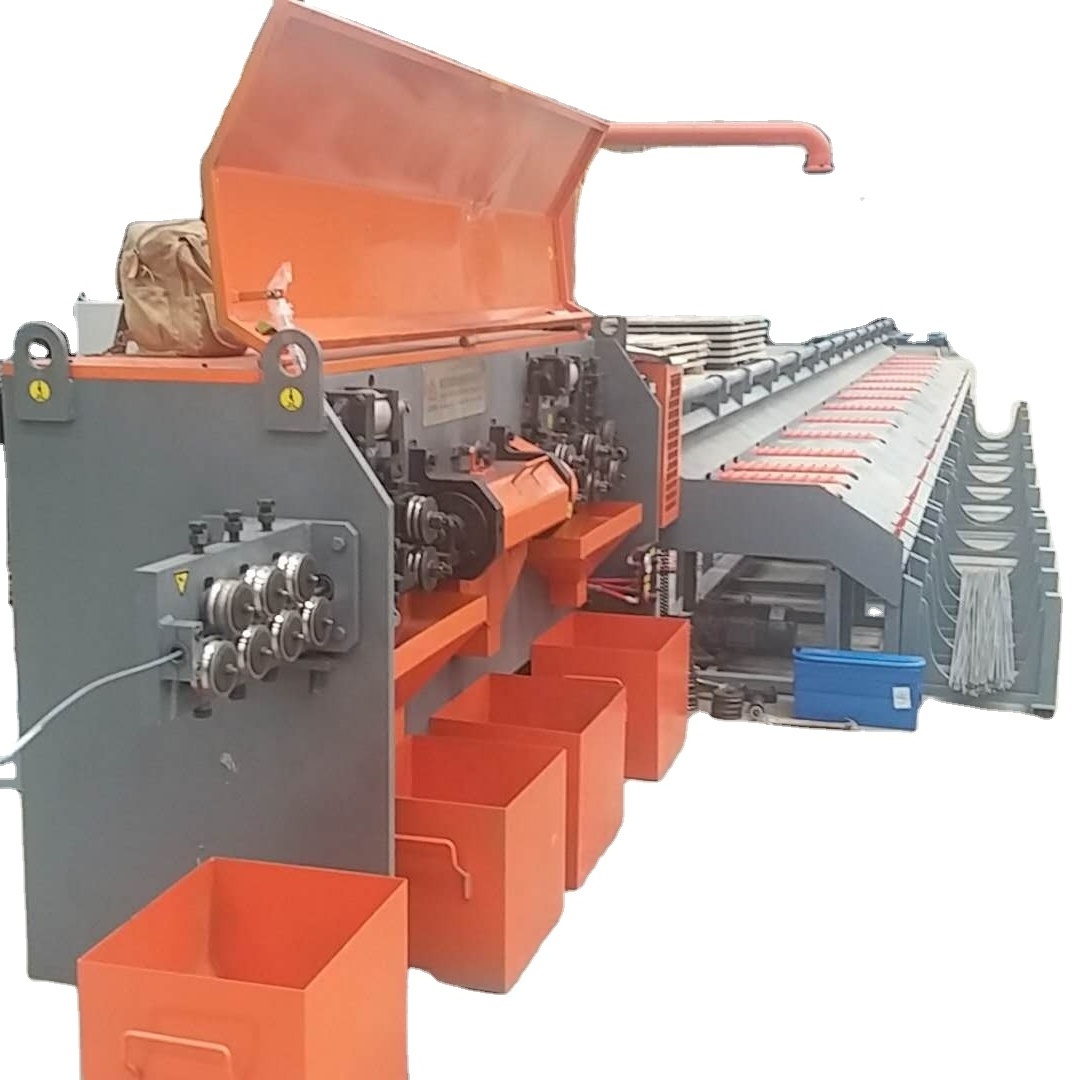

Automatic Rebar Straightening And Cutting Machine

Automatic Rebar Straightening and Cutting Machine adopt rotating straightener and high-speed flying cutting mode, widely used for straightening and cutting smooth and ribbed, hot and cold rolled structural wires.

Technical Advantages:

1.Pulling speed is adjustable(two speed or limitless adjustable, depend on the model), Max. Pulling speed 150m/min.

2.The wire length to be cut is manually set and measured using a release device in the extension.

3.High-speed flying shearcutting system. In the cutting mode, the advance wheels are relieved from pressure.

4.Operating console with programmer, display and piece counter. After run-down of the pre-programmed rod.

5.Piece numbers, the machine is automatically brought to a standstill.

1.Pulling speed is adjustable(two speed or limitless adjustable, depend on the model), Max. Pulling speed 150m/min.

2.The wire length to be cut is manually set and measured using a release device in the extension.

3.High-speed flying shearcutting system. In the cutting mode, the advance wheels are relieved from pressure.

4.Operating console with programmer, display and piece counter. After run-down of the pre-programmed rod.

5.Piece numbers, the machine is automatically brought to a standstill.

PRODUCT SPECIFICATIONS

|

Model

|

GT 5/12

|

|

Rebar diameter

|

Φ5-Φ12 mm

|

|

Cut-off Length

|

800mm-12000mm

Could customized according to client’s requirements

|

|

Pulling speed

|

~ 150m/min

|

|

Length adjust mode

|

Manual/Automatic

|

|

Cut mode

|

Servo shear

|

|

Control mode

|

PCC

(Programmable Computer Controller)

|

|

Speed Control

|

Steplessly Adjustable

|

|

Tensile strength of material

|

σb =210~650 Mpa

|

|

Length accuracy

|

±2 mm

|

|

Load capacity of Pay-off

|

3 t

|

|

Dimension

|

2.6(L) x 1.0(W) x 1.98(H)m

|

|

Gross weight

|

~3t

|

Delivery

Hot Searches