The feed machine belongs to a kind of pellet feed processing machinery. The crushed material of corn, soybean meal, soybean, bean cake, crop straw, etc. is driven by the transmission part to drive the pressure roller in the pellet machine and the template to rotate and extrude each other. The material is extruded from the hole of the template and pressed into pellets. Feed processing machinery.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

70*35*80

-

Weight:

-

80 kg

-

Application:

-

Producing Animal Feeds Pellets

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

Final product:

-

Pellet Food

-

Pellet size:

-

1.5mm-12mm

-

Material:

-

Durable Carbon Steel

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Color:

-

Clients' Requirement

-

Advantage:

-

Easy Operation High Efficiency

-

Package:

-

Wooden Case

-

Quality:

-

CE ISO Approved

Quick Details

-

Max. Capacity:

-

100kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DURABLE

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

70*35*80

-

Weight:

-

80 kg

-

Application:

-

Producing Animal Feeds Pellets

-

Raw material:

-

Wheat Bran Hay Grass Straw

-

Final product:

-

Pellet Food

-

Pellet size:

-

1.5mm-12mm

-

Material:

-

Durable Carbon Steel

-

Function:

-

Aniaml Feed Puffed Pellet Machine

-

Color:

-

Clients' Requirement

-

Advantage:

-

Easy Operation High Efficiency

-

Package:

-

Wooden Case

-

Quality:

-

CE ISO Approved

feed pellet machine

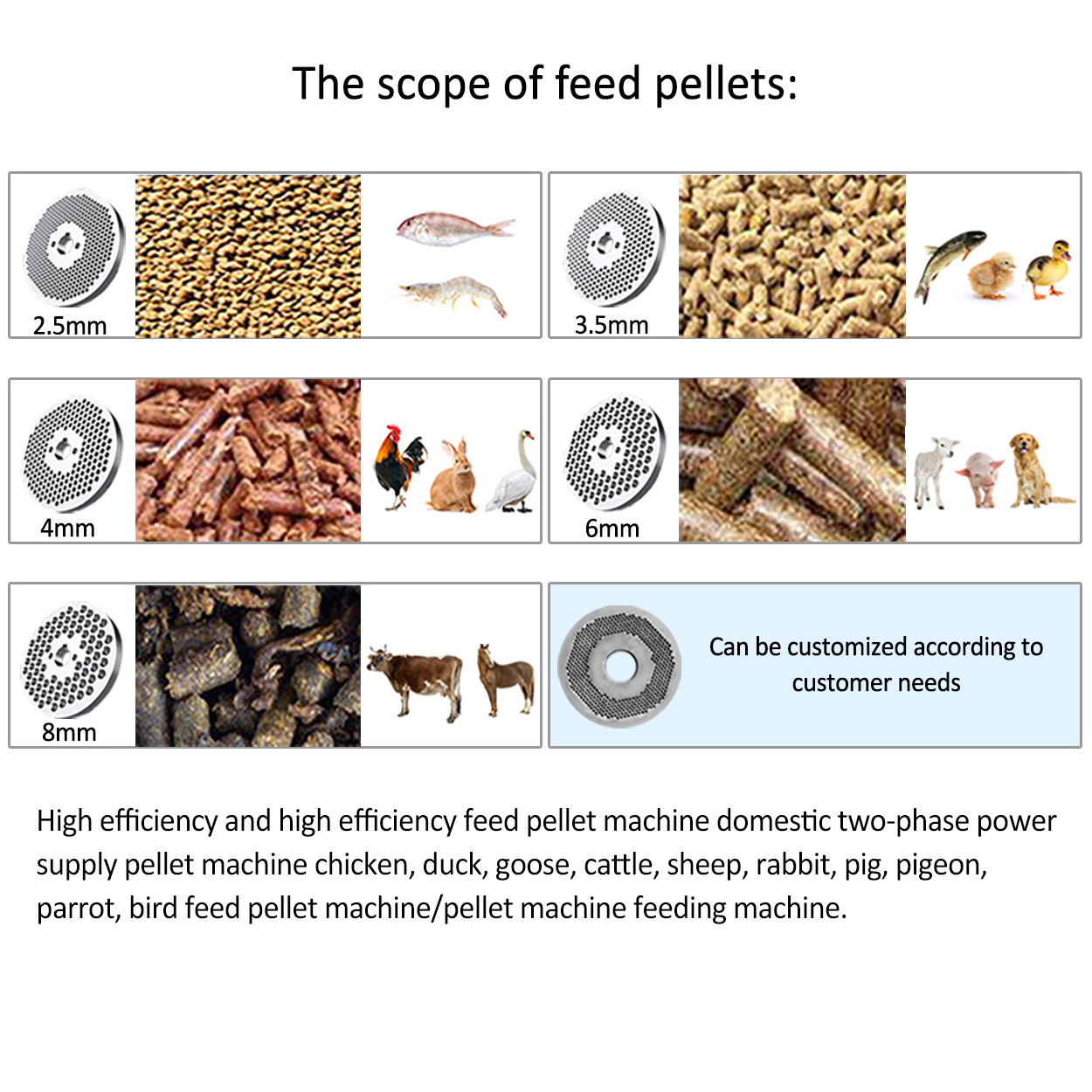

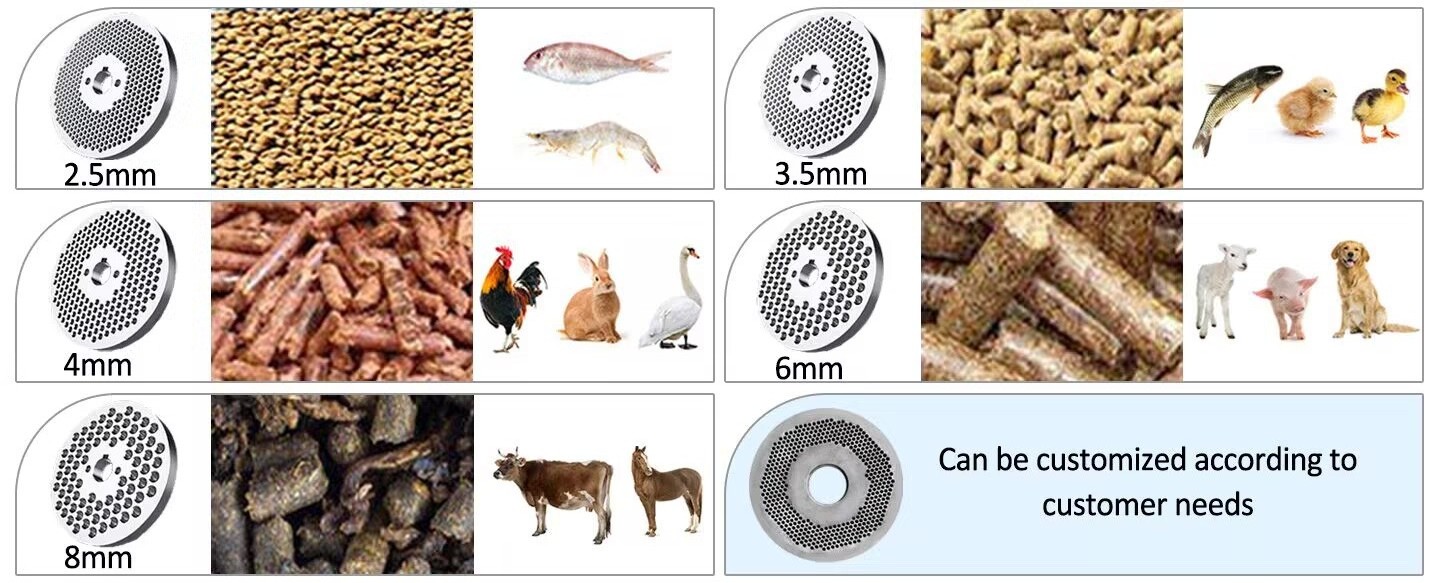

The scope of application of feed pellets:

High-efficiency and high-output feed pellet machine household two-phase electric feed pellet machine chicken, duck, goose, cattle, sheep, rabbit, pig, pigeon, parrot, bird feed pellet machine / pellet machine feed machine.

1.2.0 mm grinding disc is for breeding: parrots, thrushes, finches, and other pet birds. Be customized.

2. The 2.5 mm grinding disc is for breeding: young rabbits, chickens, ducks, geese, pigeons, birds, peacocks, aquatic fish and other small animals.

3.3-4mm discs are used for breeding: rabbits, chickens, ducks, geese, pigeons, peacocks, aquatic fish, etc. (3.0mm.4.0mm for your choice,

4. The 5-6mm grinding disc is for breeding: pigs, cattle, sheep, dogs, pigs and horses (5.0mm and 6.0mm are available for you to choose from 5-6mm specifications)

5.7-12mm (only models above 200 can be equipped with grinding discs of more than 7 meters) - generally used to make bait for large animals such as large birds and mice, which need love (7.0mm, 8.0mm, 9.0mm, 10mm, 12mm for 7-12mm specifications for you to choose)

6. If you have special requirements, please note the hole diameter requirements of the pellet machine grinding disc, and we will install, debug and deliver according to your requirements.

The diesel engine can be disassembled and operated. It is recommended to use without a stable voltage. It is convenient and fast. It can be used in any area without being restricted by the area. The slide tool takes up little space. Safer and more convenient.

When the power supply and transformer are stable, it is recommended to use the motor version of the feed pellet machine, which saves cost, low cost, high efficiency, easy to move and place, and easy to maintain.

|

Model

|

Power

(kw)

|

Capacity

(kg/h)

|

Dimension

(CM)

|

weight

(kg)

|

|

DM-125

|

4

|

80-100

|

65*30*75

|

70

|

|

DM-150

|

4.5

|

110-150

|

70*35*80

|

80

|

|

DM-160

|

5

|

150-200

|

70*35*95

|

85

|

|

DM-210

|

7.5

|

200-300

|

85*35*90

|

180

|

|

DM-230

|

11

|

350-450

|

100*40*95

|

240

|

|

DM-260

|

15

|

500-600

|

108*42*104

|

280

|

|

DM-300

|

22

|

700-800

|

130*51*121

|

380

|

|

DM-360

|

22

|

800-900

|

140*56*160

|

550

|

|

DM-400

|

30

|

1000-1200

|

150*61*180

|

750

|

Grinding cavity

The pressure wheel and grinding disc are made of high-quality chrome-manganese steel, which is more wear-resistant and durable after high-temperature quenching treatment.

adjusting nut

Adjust the distance between the grinding discs of the pressing rollers. When making granules, the nuts on both sides must be kept in balance to avoid damage to the pressing rollers and grinding discs.

Coupling

Motor coupling, just docking, easy to operate and easy to install.

Henan Durable Machine Co., Ltd. is a professional manufacturer of branch chippers, wood crushers, sawdust making machine, charcoal stick making machines, industrial drying equipment, wood pellets Machine, feed pellet machine and so on. Durable Machinery has more than 15 years of experience in wood processing equipment design, R&D and manufacturing. Advanced technology and a professional service team provide the impetus for the development of Durable Machinery. The products are exported to more than 130 countries and are well received by customers. Durable Machinery always insists on independent innovation, and invests more than 3% of sales in research and development every year.

Both sea and land transportation are available, and cargo information is provided at any time, and we will remind you before the ship arrives. We will specially make iron frames for containers, and different sizes of iron frame machines can be configured according to the type of container. The packaging will be sandblasted and sprayed with high-quality paint, pp bubble product packaging. Loading container, in order to reduce the transportation cost as much as possible, we will pack the machine with moisture-proof film and put it in impact-resistant wooden box in advance.

1: Is the

pellet

dry in and dry out?

Answer: What we usually call dry in and dry out means that the raw materials can be processed directly by putting them in. This is a misunderstanding, and it is not really dry in and dry out, because the raw materials used contain a certain proportion of water. If the overall humidity is between 10%-15%, there is no need to add water, and it can be done directly. If the raw material is very dry, you can spray a little water, a small amount, about 3%6-5%, so good Molding, does not affect storage. It is the feed processed by the feed factory, which also adds water or steam. There is no pellet machine in the country that can process pellets with 100% pure dry raw materials. This is determined by its own principle.

2: Why is the pellet machine always blocked when it is used for the first time?

Answer: The difference between the pellet and other machines is that the first time a new machine or a new grinding disc is used, the grinding disc must be ground first. The holes on the grinding disc are drilled out one by one. The hole wall is not smooth. Use it directly. Made of raw materials, the resistance is high and it is easy to block. After repeatedly grinding through the hole of the grinding disc with the abrasive material, the material can be made normally. For specific grinding methods and ingredients, please refer to the manual or the video on the home page.

3: Can single-phase electricity use a pellet machine? Why do some people say that it is easy to jam the machine

?

Answer: There are only two types of single-phase pellet machine, 120 model and 150 model. If the single-phase power supply is unstable and the power is insufficient, the machine will be stuck. There are many reasons for the machine to be stuck. , For example, if the voltage is unstable, the wiring is too long, the quality of the motor is too poor, and the raw materials are too rough, the machine will be stuck and hold up. The specific situation needs to be analyzed in detail, but if the voltage at home is obviously unstable, then we do not recommend To buy, first see if it can solve the electricity problem or choose a diesel engine model.

4: Does the granulator have any requirements for the size of raw materials?

Answer: Grain materials can not be crushed, but forage and straw materials must be crushed before they can be processed. It is best to use powder materials, because the granules made from powder materials are evenly nutritious.

Hot Searches