- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

METO

-

Year:

-

2024

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2000*800*1400mm

-

Hollow part volume:

-

2liter

-

Power (kW):

-

10

-

Weight (KG):

-

679 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Blow Molding Machine

-

Type:

-

Stretch Pet Blow Moulding

-

Cavity:

-

2

-

Bottle:

-

2L

-

Package:

-

Wooden case, Film

-

Delivery:

-

15days after drawing confirmed

-

Shipping:

-

by sea

-

Port:

-

Ningbo, China

-

Weight:

-

1000kg

Quick Details

-

Neck Diameter(mm):

-

60 mm

-

Max.Bottle Diameter(mm):

-

100 mm

-

Max.Bottle Height(mm):

-

325 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

METO

-

Year:

-

2024

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2000*800*1400mm

-

Hollow part volume:

-

2liter

-

Power (kW):

-

10

-

Weight (KG):

-

679 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Blow Molding Machine

-

Type:

-

Stretch Pet Blow Moulding

-

Cavity:

-

2

-

Bottle:

-

2L

-

Package:

-

Wooden case, Film

-

Delivery:

-

15days after drawing confirmed

-

Shipping:

-

by sea

-

Port:

-

Ningbo, China

-

Weight:

-

1000kg

Product Application

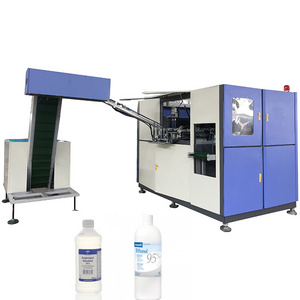

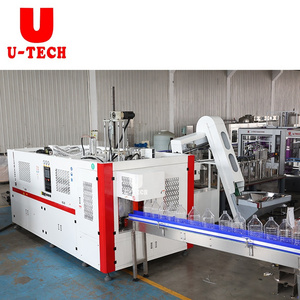

1000BPH plastic blowing machine/pet bottle making mold machine price manual blower 2000ml drinking water bottles fast shipping

METO is a factory specialized in making the PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc. Beverage bottle, cosmetic bottle, medicine bottle, jar etc.

We have many many types of the machine, with automatic, manual and semi automatics.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .