Lead time:

4-6 weeks

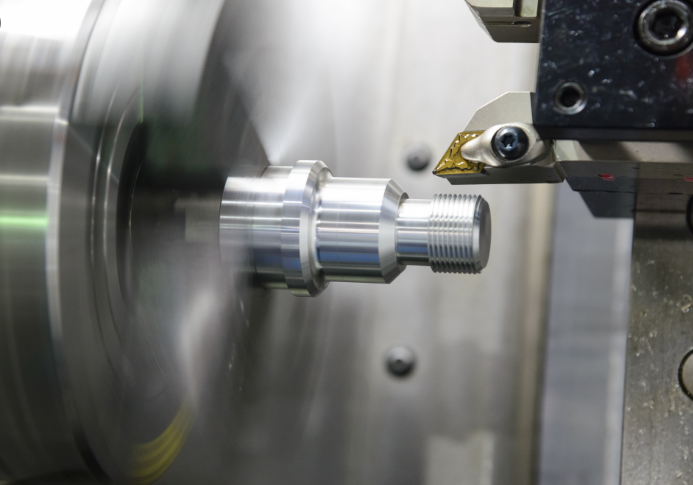

Process : Investment casting Stainless

Die Casting Aluminum

Sand casting Grey Iron

Added Value service ·

Machining

·

Heat Treatment

·

Finishing

Quality Assurance:

100% inspection