- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Depends on capacity

-

Size:

-

Depends on capacity

-

Power:

-

According to customization

-

Weight (KG):

-

1800.0

-

Product name:

-

Sewage Treatment System

-

Certificate:

-

ISO9001 CE

-

Type:

-

integrated sewage treatment equipment

-

After-sales Service Provided:

-

Video Technical Support\Online Support

Quick Details

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

WTEYA

-

Material:

-

Wooden package with film, customized

-

Weight:

-

Depends on capacity

-

Size:

-

Depends on capacity

-

Power:

-

According to customization

-

Weight (KG):

-

1800.0

-

Product name:

-

Sewage Treatment System

-

Certificate:

-

ISO9001 CE

-

Type:

-

integrated sewage treatment equipment

-

After-sales Service Provided:

-

Video Technical Support\Online Support

Product Description

|

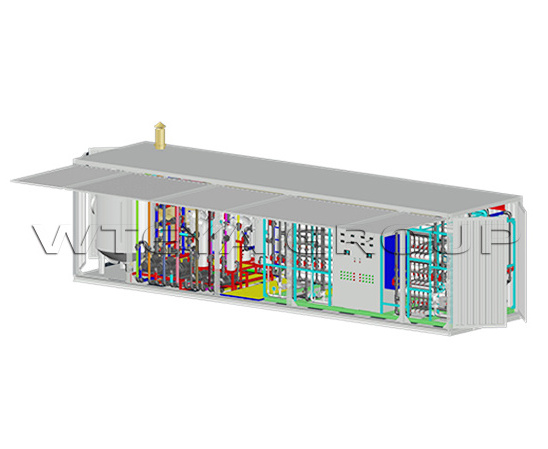

Integrated Sewage Treatment Equipment

WTEYA's integrated wastewater treatment equipment, as a movable membrane complete set, features stable performance, high water production rate, short construction period, and small footprint. It is primarily used for treating landfill leachate and other types of high-salinity wastewater, with all components of the equipment made from quality brands. This equipment is usually designed compactly to meet different wastewater treatment needs.

|

|

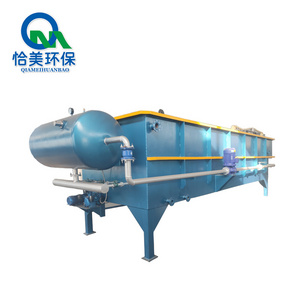

Product Composition

The integrated sewage treatment equipment t mainly consists of water pumps, membrane elements, filters, instruments, electrical control systems, valves, pipelines, and other systems.

|

Details Images

Product Parameters

|

Technical Principle:

Reverse osmosis, also known as reverse filtration, is a membrane separation process that uses pressure difference as the driving force to separate solvents from solutions. By applying pressure to the feed side of the membrane, when the pressure exceeds its osmotic pressure, the solvent will permeate in the opposite direction of natural osmosis. As a result, the permeated solvent, i.e., the penetrant, is obtained on the low-pressure side of the membrane; the concentrated solution, i.e., the concentrate, is obtained on the high-pressure side. If seawater is treated with reverse osmosis, fresh water is obtained on the low-pressure side of the membrane, and concentrated water on the high-pressure side.

The reverse osmosis membrane is the core component for achieving reverse osmosis, a type of artificial semipermeable membrane with certain characteristics, analogous to a biological semipermeable membrane, typically made from polymeric materials such as cellulose acetate, aromatic polyamide, or aromatic polyimide membranes. The diameter of the surface micropores is generally between 0.5~10nm, and the size of the permeability is related to the chemical structure of the membrane itself. Some polymeric materials have good salt rejection properties but do not allow water to pass through quickly. Other polymeric materials have chemical structures with many hydrophilic groups, thus allowing water to pass through relatively quickly. Therefore, a satisfactory reverse osmosis membrane should have an appropriate permeation rate or desalination rate.

|

|

Product Features/Advantages:

1.Utilizes mature technology to meet new standard requirements.

2.Wide application scope: suitable for high concentration organic wastewater treatment such as landfill leachate, leachate from waste incineration power plants, and biogas from kitchen waste treatment plants.

3.Realizes the modular combination design of skid assembly, fast and convenient assembly and disassembly.

4.Short construction period.

5.Small footprint.

6.System stability, energy-saving automation, and simple operation.

7.Convenient maintenance and management.8.Strong resistance to fouling and shock loads.

|

|

Standardized and Customized Services

We pursue excellence in smart manufacturing. By integrating ERP, PLM, MES, CAPP and other advanced information systems with lean production concepts, relying on digital transformation and automation upgrades, we actively expand the application of big data analysis and artificial intelligence technology, and are committed to intelligent manufacturing to provide customers with excellent products and services.

We not only provide a series of standardized products that have been rigorously tested and have stable performance to meet a wide range of industry needs. We also provide customized services, and our professional design team provides customers with customized solutions to meet their unique needs. Model customers work closely together to ensure that each piece of equipment accurately meets the customer's process requirements and production processes. WTEYA provides all-round services and creates high-quality mechanical products and system solutions with ingenuity.

|

|

Application Scope:

The integrated wastewater treatment equipment is suitable for the treatment of high-concentration organic wastewater such as landfill leachate, leachate from garbage incineration power plants, and biogas from kitchen waste treatment plants.

|

Hot Searches