- Product Details

- {{item.text}}

Quick Details

-

Process:

-

cut,weld,punch,printing

-

Usage:

-

Forming concrete slab ,beam

-

Technique:

-

CO2 arc welded

-

Raw material:

-

PVC

-

Color:

-

gray or according to your order

-

Reusable time:

-

50 times

-

Weight:

-

15kg

Quick Details

-

Place of Origin:

-

Shandong, China

-

Certificate:

-

ISO9001:2008

-

Product name:

-

Aluminum formwork template

-

Process:

-

cut,weld,punch,printing

-

Usage:

-

Forming concrete slab ,beam

-

Technique:

-

CO2 arc welded

-

Raw material:

-

PVC

-

Color:

-

gray or according to your order

-

Reusable time:

-

50 times

-

Weight:

-

15kg

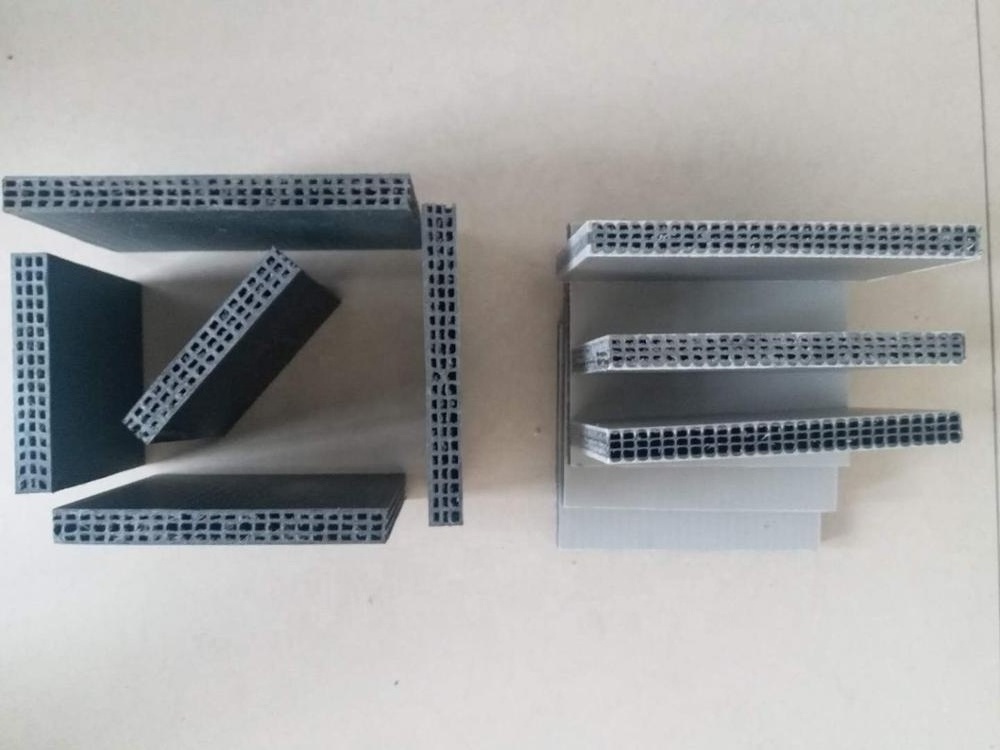

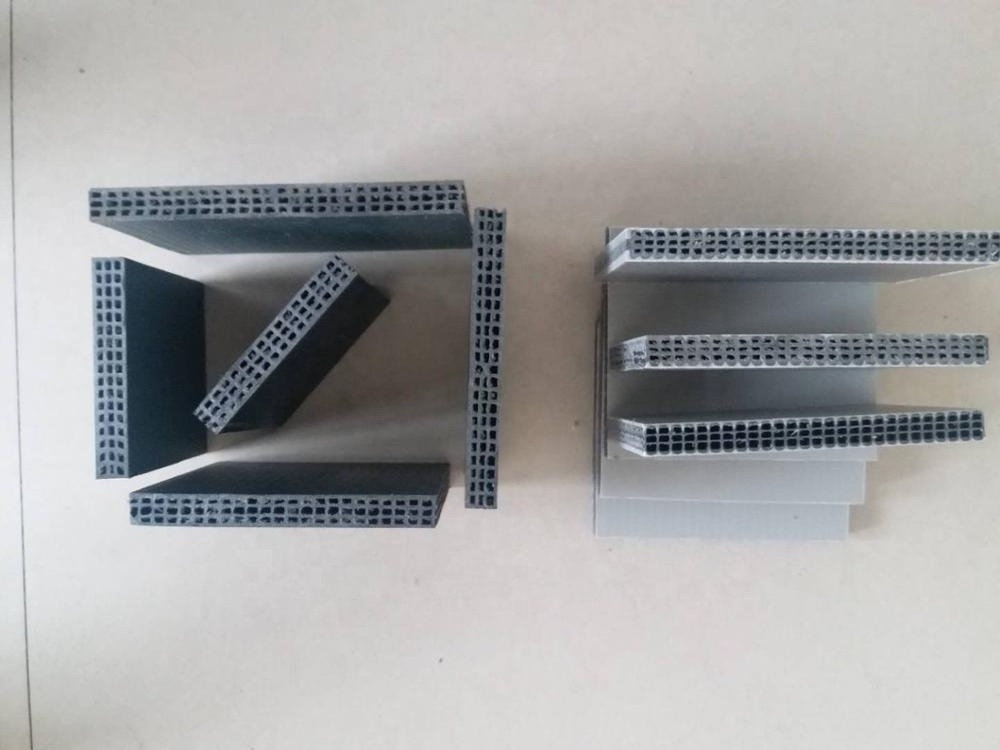

Recycled Plastic Formwork for Construction with Competitive Price

Specification and Type

| Thickness, mm | Specification, mm | Average Weight, kg |

| 14mm | 915mm*1830mm | 10kg |

| 14mm | 1220mm*2440mm | 18kg |

| 15mm | 915mm*1830mm | 10kg |

| 15mm | 1220mm*2440mm | 18kg |

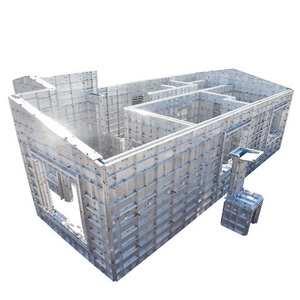

General Operation And Note Of Instrument For Building Template

1. Method of use as well as wooden template, hollow plastic template reinforcement direction with batten direction placed in cross shaped.

2. No need to smear the mold release agent before using templates.

3. When cast-in-placed the flat plate, spacig between the keels should be 20-25cm, and the spacing between the wall plate and keel should be 10-20 cm.

4. The seam-line between templates should be taped.

5. The length of nail should not be too long, generally about 30-35mm.

6. The strength to drive nails should be moderate.

7. When removing the formwork, should start from the small part of one end, the support and the plates should be removed at the same time aiming at preventing the template widespread drops, don't let the corner drop on the ground vertically.

8. The template accesses to be mixed used with wood veneer, bamboo veneer and other material plate.

|

Size |

915mm*1830mm or as you request |

|

Thickness |

15mm or as you request |

|

Packing details |

Standard export package on pallet |

|

Application |

Construction, Formwork, Truck/Container Flooring, Packaging |

|

Payment |

T/T or L/C at sight |

|

Delivery time |

Within 15 days after receiving deposit or Original L/C at sight |

|

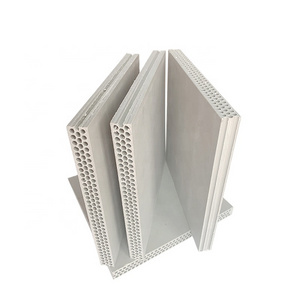

1, Reduce the cost. New type of building template can revolve more than 50 times, the average cost once is lower than 2 yuan. |

|

2, Energy saving and environmental. There ' s no harmful gas completely in the new type of building template. |

|

3, Extreme smooth surface. New type of building template has smooth surface, because of this the demould effect is better than fresh water formwork, no need to plasterer twice. |

|

4, Very well stability. The new type of building template has excellent property of cold-resistant, hot-resistant, aging-resistant and no deformation, low expansion coefficient. |

|

5, High performance in the construction. New type of plastic building formwork has high strength, tenacity, no breaking, no layering. |

|

6, Porting and simple operated. The new type building formwork is very light, easy to install. For example it is 15kg ,only 1/2 weight of wooden template, reduce the worker’s time and effort effectively. |

|

7, Can transpose at high price. The template scrapped can also transpose to a new one, only need to pay for the process. |

|

8,Convenient storage. The new type building template can withstand the corrosion of acid, alkali, and the damage by worms, so the storage has no specific demand for the environment. |

|

9, Simple and convenient demoulding. No need to brush the release agent, demould breezily. |

|

10,High changeability. The new type template can be incised, cut and drilled arbitrarily. |

| SIZE(mm) | THICKNESS(mm) | WEIGHT(kg) | CONTAINER LOADING (pcs) | ||

| 20FT | 40FT | 40HQ | |||

| 0.915*1.83 | 14 | 13 ±1 | 900 | 1800 | 1980 |

| 1.22*2.44 | 15 | 25 ±1 | 560 | 1120 | 1120 |

| 1.22*2.44 | 16 | 26 ±1 | 440 | 880 | 1026 |

| 1.22*2.44 | 18 | 28 ±1 | 400 | 800 | 1000 |