- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

35-65 pcs/min

-

Weight (KG):

-

1000

-

Voltage:

-

220V380V 50/60HZ, 5KW

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Utrust

-

Dimension(L*W*H):

-

7600*3900*3600mm

-

Product name:

-

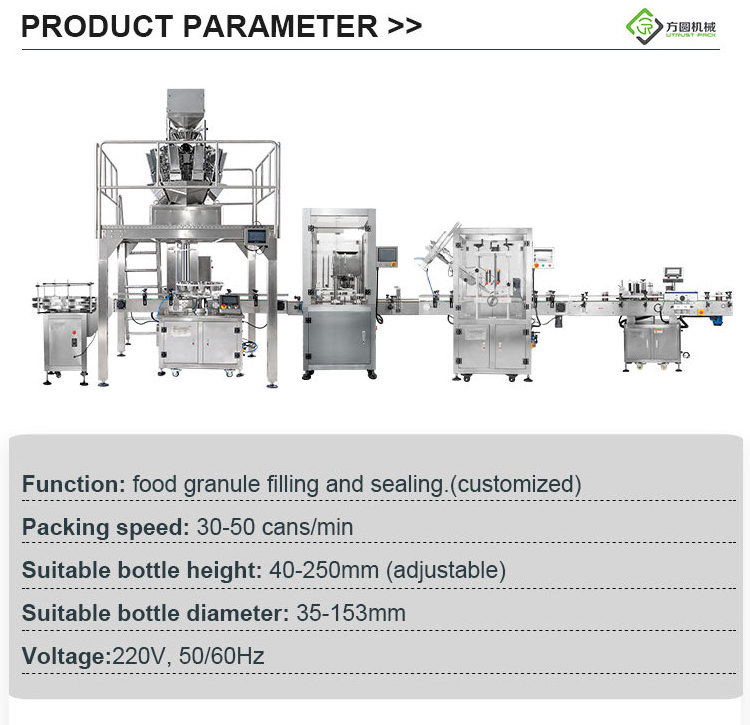

Gummy Bear Plastic Cans Filling Machine Assorted Candy Packing Machine

-

Product capacity:

-

40-60 pcs/min

-

Suitable canister height:

-

40-200mm (adjustable)

-

Suitable canister diameter:

-

35-100mm

-

Air Consumption:

-

0.6~0.8Mpa

-

Size:

-

7600*3900*3600mm

Quick Details

-

Function:

-

FILLING, Labeling, Capping, Sealing

-

Packaging Type:

-

CANS, Bottles

-

Packaging Material:

-

Plastic, Paper, Metal, Glass

-

Production Capacity:

-

35-65 pcs/min

-

Weight (KG):

-

1000

-

Voltage:

-

220V380V 50/60HZ, 5KW

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Utrust

-

Dimension(L*W*H):

-

7600*3900*3600mm

-

Product name:

-

Gummy Bear Plastic Cans Filling Machine Assorted Candy Packing Machine

-

Product capacity:

-

40-60 pcs/min

-

Suitable canister height:

-

40-200mm (adjustable)

-

Suitable canister diameter:

-

35-100mm

-

Air Consumption:

-

0.6~0.8Mpa

-

Size:

-

7600*3900*3600mm

Gummy Bear Plastic Cans Filling Machine Assorted Candy Packing Machine

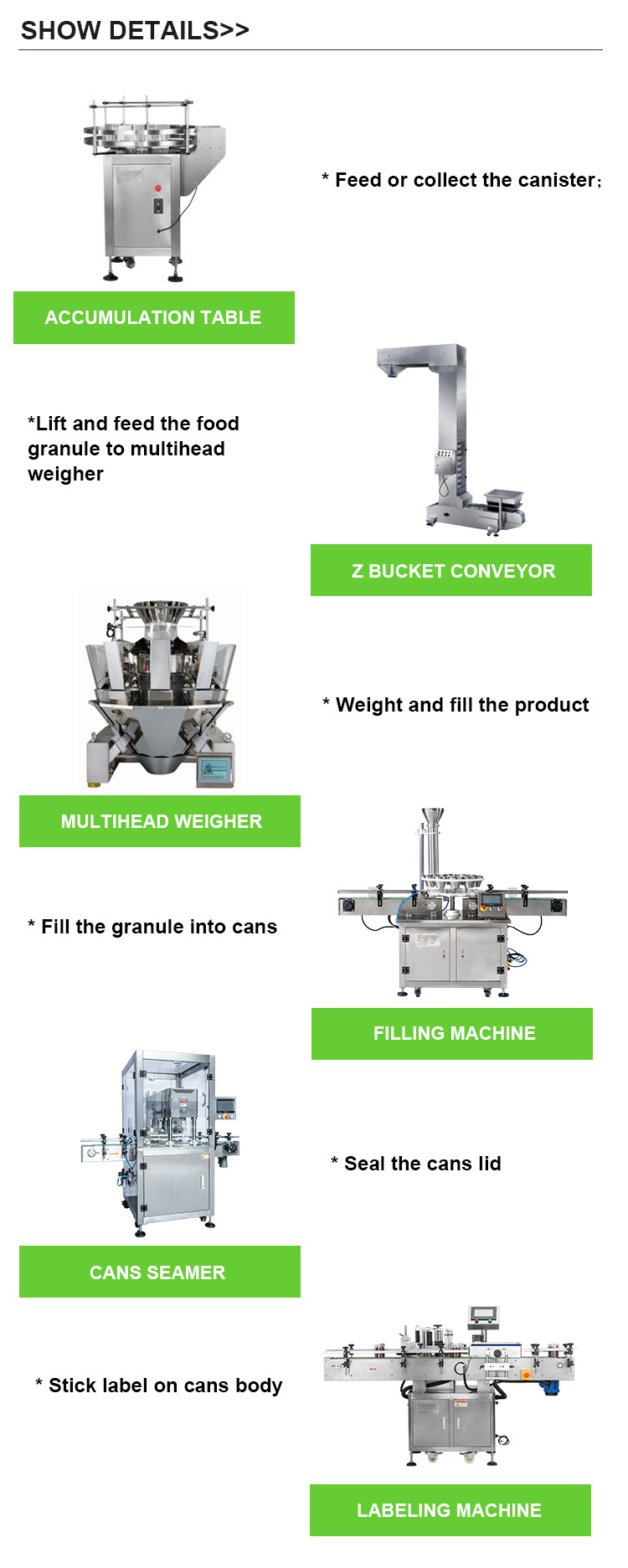

Steps for Raisins Apricot Kenels Canned Food Packaging Production Line:

1. The accumulation table will unscramble and lined up the cans/bottle first.

2. The granule material lifted up by Z bucket conveyor and weight by multi-head weigher .

3. The granule material get filled into cans by turntable filling machine .

4. The filled cans will get into the can sealing machine and sealed by it.

5. The sealed cans get into the snap capper for putting dust-proof caps on.

6. Cans get labeled by the label machine .

7. Cans are collected by the accumulation table and are ready to get load into shipping boxes.

Advantages of the Automatic granule packing production line:

1. Automatically material conveying, weighing, canning, labeling to eliminate the unnecessary labor cost and promote production efficiency at the same time.

2. Advanced Tech: Human-Computer Interaction Touch Screen, PLC Controller, Photo electricity Sensor, High Accuracy Servo Motor etc.

3. Auxiliary device: like nitrogen gas generator or liquid nitrogen storage tank and other device could be assemble together depend on your request.

4. Application: it is suitable for plastic/metal cans packing and widely used in food, pharmaceutical, chemical, commodity industries etc.

Guangzhou Utrust Packaging Equipment Co., Ltd. Locates at the beautiful backyard garden of Guangzhou city and just 45 minute drive from Guangzhou Baiyun Airport.

Utrust Pack is an enterprise integrating R&D, design, production, sales and installation. It has more than 25 years of experience in various packaging automation equipment and more than 34 patents. Design customization is available for client’s factory layout.

The company mainly produces and sells various packaging equipment such as can sealing machine, vacuum nitrogen filling sealing machine, capping machine, powder/granule/liquid packaging line, robot sorting and so on.

Products are mainly used in food, beverage, medicine, chemical and other industries and sell well all over the world.

The company culture "People leading value for people", which keeps us thinking that helping each other for a better life and a better world.

The company has built a very professional R&D, production, quality control and project management team. The company’s core technical personnel graduated from key universities such as Xi’an Jiaotong University and Guangdong University of Technology.

We have a number of patents and project experience, the engineer team has leading R&D strength, more than 80% of them have a bachelor degree, and some of the engineers have worked for more than ten years.

We insist on making high-quality products, providing customers with professional customized services and better packaging solutions, and bringing customers safe, reliable and cost-effective packaging machinery and service. We will always be your trustworthy supplier for automation equipment and service.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.