- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

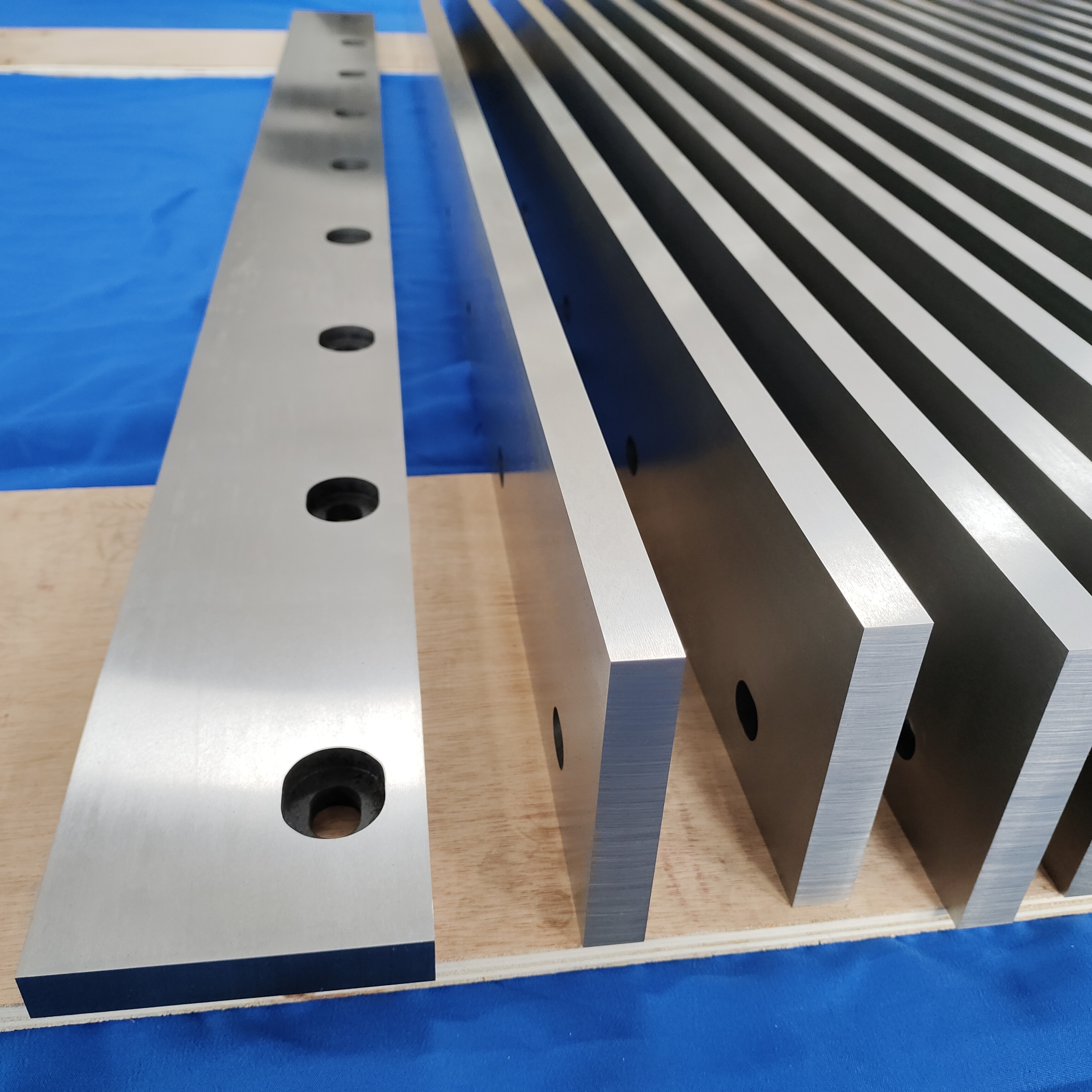

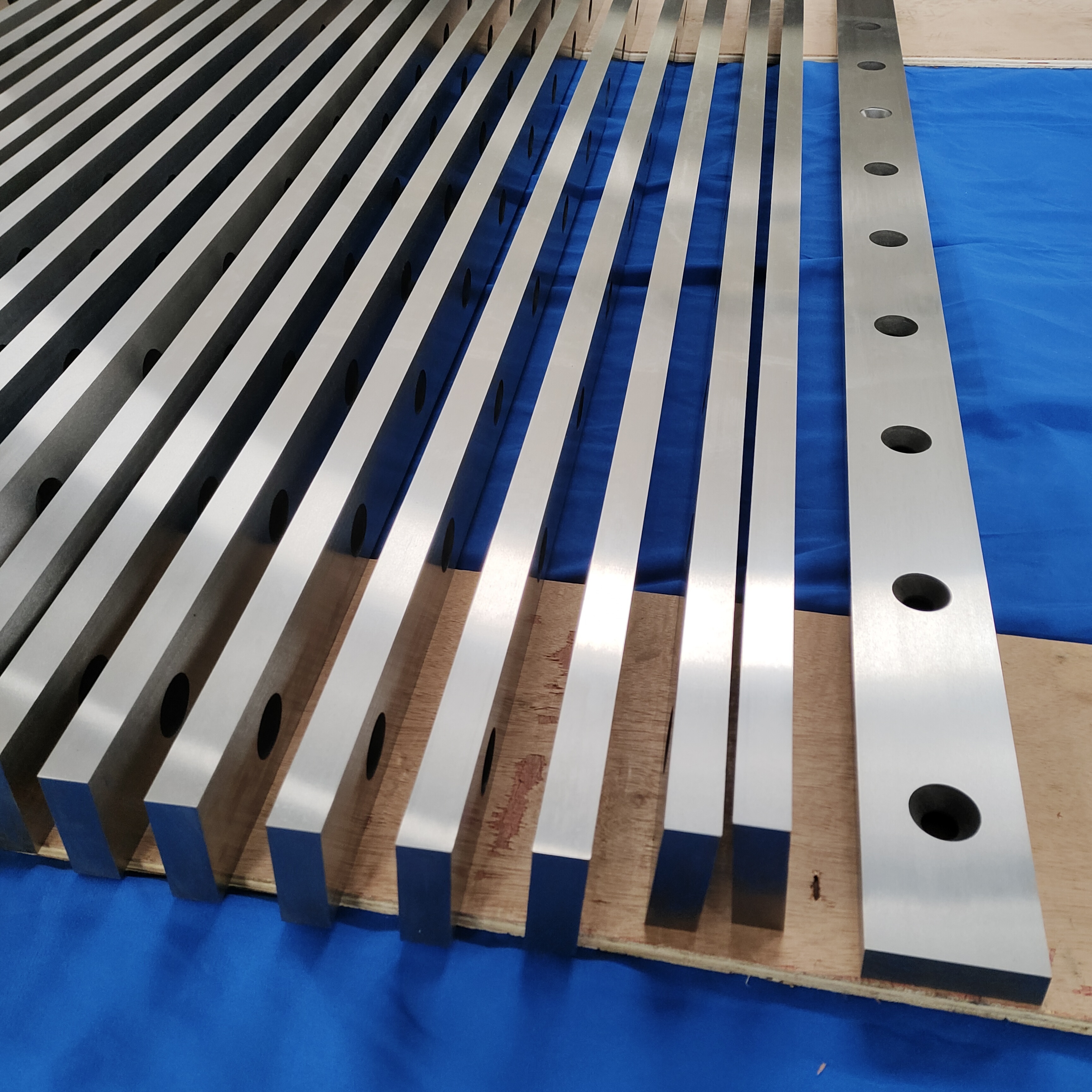

shearing machine blade

-

Application:

-

Industrial Process Usage

-

Material:

-

9CrSi, H13, Cr12MoV, D2

-

Advantage:

-

Perfect High Cutting Efficiency

-

Usage:

-

Rewinding Machine Slitting Industrial

-

Keywords:

-

Original Sharp Blade

-

Size:

-

Cusomized

-

Shape:

-

Long

Quick Details

-

Core Components:

-

steel

-

Brand Name:

-

Shuper

-

Type:

-

Cutting Parts

-

Product name:

-

shearing machine blade

-

Application:

-

Industrial Process Usage

-

Material:

-

9CrSi, H13, Cr12MoV, D2

-

Advantage:

-

Perfect High Cutting Efficiency

-

Usage:

-

Rewinding Machine Slitting Industrial

-

Keywords:

-

Original Sharp Blade

-

Size:

-

Cusomized

-

Shape:

-

Long

|

508mm*80mm*25mm

|

1025mm*80mm*20mm

|

1270mm*80mm*25mm

|

|

1100mm*80mm*20mm

|

1100mm*100mm*25mm

|

1300mm*80mm*20mm

|

|

1300mm*100mm*25mm

|

1300mm*125mm*32mm

|

3100mm*58mm*20mm

|

|

The product name

|

Shearing Machine Blade

|

|

Brand

|

Shuper

|

|

Meterial

|

9CrSi, H13, Cr12MoV, D2

|

|

Certification

|

ISO9001

|

|

Size

|

Please see the chart below or customized

|

|

Tolerancing

|

±0.02 ~ ±0.05

|

|

Hardness

|

50 HRC ~ 62 HRC

|

|

Application

|

Suitable for light industry, aviation, shipping, metallurgy, instrumentation, electrical appliances, stainless steel products, steel structure building and decoration industry.

|

|

Packing

|

1. Anti-rust oil

2. Wrap PE coated wax paper

3. Wooden box packaging

|

|

Machine Model

|

Length (mm)

|

Width (mm)

|

Thickness (mm)

|

Pieces

|

|

QC12Y-4*2000

|

1050

|

63

|

16

|

4

|

|

QC12Y-16*2000

|

1025

|

100

|

25

|

4

|

|

QC12Y-12*2500

|

1300

|

125

|

25

|

4

|

|

QC12Y-16*2500

|

1300

|

80

|

20

|

4

|

|

QC12Y-25*2500

|

1300

|

125

|

32

|

4

|

|

QC12Y-16*3000

|

1100

|

100

|

25

|

6

|

|

QC12Y-8*3200

|

1100

|

100

|

20

|

6

|

|

QC12Y-20*4000

|

1025

|

100

|

30

|

8

|

|

QC12K-4*2500

|

1300

|

80

|

20

|

4

|

|

QC12Y-6*2500

|

1300

|

80

|

20

|

4

|

|

QC12Y-12*2500

|

1300

|

100

|

25

|

4

|

|

QC12Y-20*2500

|

1300

|

125

|

32

|

4

|

|

QC12K-4*3200

|

1100

|

80

|

20

|

6

|

Carbon-bonded tool steel:

Carbon-bonded steel generally uses 65#, 75# steel, T8, T10 and other materials. The heat treatment hardness of the blades produced from this material is within the range of HRC57-59 degrees. It is suitable for ordinary low-carbon cold-rolled plates, ordinary A3 plates and scrap materials. Recycling shearing, this feature is low cost and affordable product price.

Low alloy tools:

Commonly used materials for low alloy tool steel blades are: 6Crw2si, Cr5Mo1V, 9CrSi, Cr12MoV, STD11, etc. The heat treatment hardness of the blade is in the range of HRC58-62 degrees. It is specially used to cut stainless steel and is suitable for hot-rolled plates, stainless steel, Shearing of medium and thick plates.

Alloy tool steel:

Shearing blade materials of alloy tool steel include LD, W6Mo5Cr4V2, H13, etc. Blades made of this material are used for hot-rolled steel, hot shearing of medium and thick steel plates, etc. This feature is high temperature resistance and not easy to anneal, and is used in hot rolling and hot shearing processes in steel plants.

Suitable for light industry, aviation, shipping, metallurgy, instrumentation, electrical appliances, stainless steel products, steel structure building and decoration industry.

Shanghai Tian'an CNC Machine Tool Co., Ltd is a production enterprise specialising in manufacturing many kinds of industrial blades. My company covers an area of 1,800 m² (building area is about 1,500m² and has 40 employees in total. My company's management and technical team has been engaged in blade manufacturing for nearly 20 years, with rich experience in blade design and manufacturing. We always insist on providing customers with better quality and more stable products and services.

My company's professional technicians, high-quality processing team and advanced and strict management system to ensure the stability of product quality. The products are widely used in metal processing slitting, textile and chemical fibre, tobacco, printing, glass fibre, packaging, papermaking, household paper, plastic film, food processing, metallurgy and chemical industry, rubber tyre, leather, etc. My company has more than 30 machining equipments: numerical control lathe, CNC, high-precision internal and external cylindrical grinders (self-developed), grinding machines, alloy sintering furnace, vacuum heat treatment furnace, deep cooling equipment and so on. With excellent equipment, exquisite technology, strict inspection, advanced management, so that the quality of our products is always in the forefront of the industry, the products are exported to Europe and the United States, the Middle East, Southeast Asia and the Asia-Pacific region, by the majority of users praise and trust.

Insisting on innovation and pioneering, Shanghai Tian'an CNC Machine Tool Co., Ltd is your most faithful and reliable partner, and we sincerely welcome new and old customers to call and write to us for consultation!

Q1. Are you manufacturer?

A: Yes, we are professional manufacturer with over 20 years experience in industrial blade.

Q2: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock and it is 15-30 days if the goods are not in stock, which it is according to quantity.

Q3: How can I get a quotation?

A: You can send us inquiry directly. We will reply you asap!

Q4: What are the material and hardness?

A: It depends on your material and application, different materials have different hardness. We will provide the most suitable hardness for your blades according to the application.

Q5. Do you provide free samples?

A: Yes. usually we provide free samples for testing under the condition of freight paid by the customer. if you are interested in our products, you can contact us any problem. We are pleasure to help you.

Hot Searches