- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

27.12MHz

-

Welding Area:

-

depend on the product

-

Dimensions:

-

1800X900X1750mm

-

Usage:

-

Blister packaging industry

-

Weight (KG):

-

200 KG

-

Power (kW):

-

27.12MHz

-

Marketing Type:

-

Other

-

Power supply:

-

380V 50Hz

-

Vibrating frequency:

-

27.12MHz

-

Electron tube:

-

Silicon diode

-

Pressure way:

-

Air pressure

-

Cooling type:

-

Air cooling

-

Oscillator:

-

5kw , 8kw

-

Application:

-

PVC welding

-

Name:

-

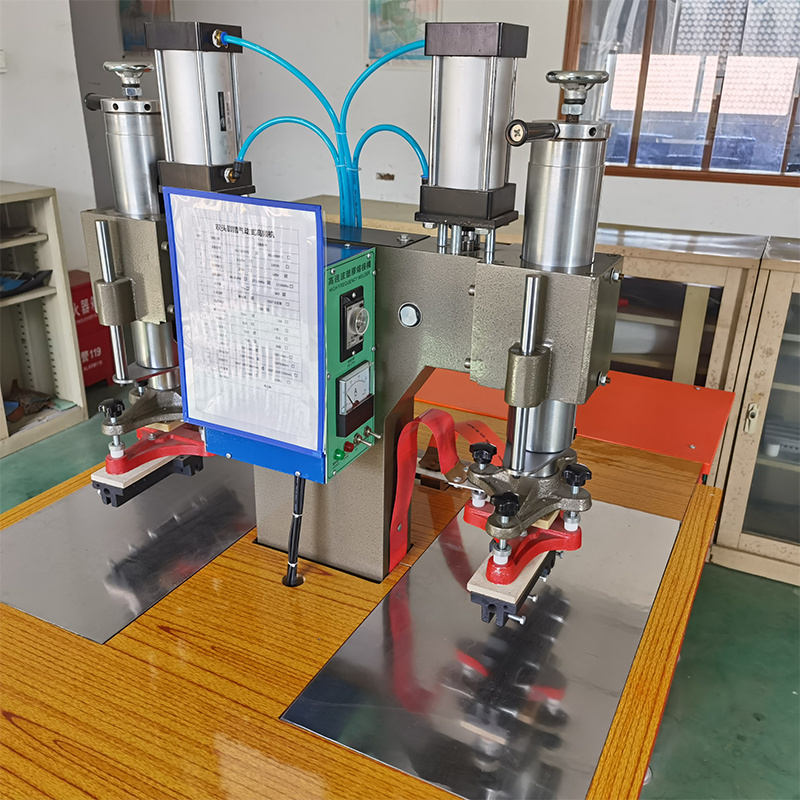

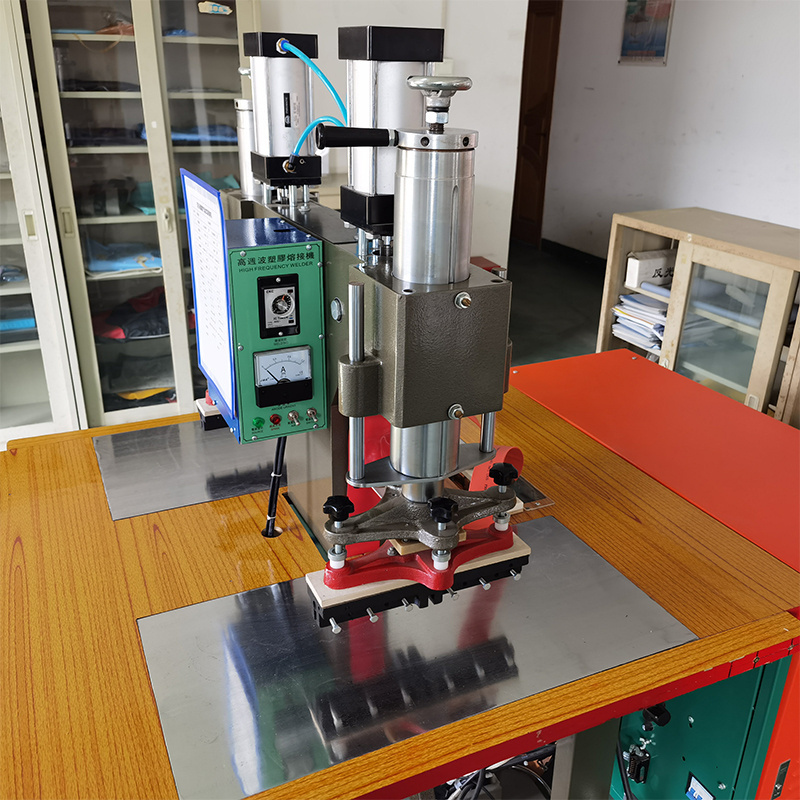

High frequency welder

-

Customized service:

-

Provided

-

Material:

-

PVC TPU PETG APET

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

M

-

Voltage:

-

380v

-

Frequency:

-

27.12MHz

-

Welding Area:

-

depend on the product

-

Dimensions:

-

1800X900X1750mm

-

Usage:

-

Blister packaging industry

-

Weight (KG):

-

200 KG

-

Power (kW):

-

27.12MHz

-

Marketing Type:

-

Other

-

Power supply:

-

380V 50Hz

-

Vibrating frequency:

-

27.12MHz

-

Electron tube:

-

Silicon diode

-

Pressure way:

-

Air pressure

-

Cooling type:

-

Air cooling

-

Oscillator:

-

5kw , 8kw

-

Application:

-

PVC welding

-

Name:

-

High frequency welder

-

Customized service:

-

Provided

-

Material:

-

PVC TPU PETG APET

|

Model

|

M-5000F/S

|

M-8000F/S

|

|

|

HF Output

|

5KW

|

8KW

|

|

|

High voltage input

|

8.5KVA

|

13KVA

|

|

|

Power supply

|

380V / 50HZ

|

|

|

|

Rectifier

|

SILICON DIODE

|

|

|

|

Overcurrent protection

|

Auto

|

|

|

|

Spark protection

|

Relay

|

|

|

|

pressure

|

Cylinder

|

|

|

|

Mechanical movement distance

|

70mm

|

|

|

|

Cooling mode

|

Air cooling

|

|

|

|

Tube type

|

7T85RB

|

7T69RB

|

|

|

Upper fixture size

|

320*30mm

|

|

|

|

Worktable size

|

350*700mm

|

|

|

|

Overall Dimension

|

1140*1700*1750mm

|

|

|

|

Net Weight

|

350KG

|

400KG

|

|

Wuxi Marcia Founded in 2012 is focusing on mechanical equipment, customized mold services, with more than 10 years of overseas export business experience, and has our own CNC machining center.

The main products are plastic welding equipment, such as hot melt welding equipment, high frequency welding equipment, ultrasonic welding equipment; customization services including welding mold tooling customization, bottle mold customization, mold core mold cavity thread and other molding parts customization, as well as related plastic products supply.

Through more than 10 years of development and accumulation, the products are exported to more than 20 countries, such as the United States, Canada, Mexico, Peru, Chile, Indonesia, Thailand, Malaysia, Uzbekistan and so on.

Adhere to the "integrity first, heart service" principle, is committed to become your trustworthy partner in China, we warmly hope to work together to create a better future!

Question: How can I make the correct welding mold for replacement work against the existing welding machine?:

A.Concerning the welding horn, please make sure the ultrasonic frequency first ,20khz or 15khz.

Then measure the welding zone dimension ,namely length by width. Last one is to measure the installation screw size .

B ,refer to the welding roller , it is better to supply the relation drawing , if it is impossible .

Please show us your final product welding shape , and please measure the shaft end dimension which is necessary .

Question: How about the procedure after getting your order :

A. around 5 business days for us to make the machine against your order.

B. related testing video , machine pictures are sent to you before packing

C. packing procedure pictures for you

D. Arrange the shipping for you, and keep you informed the tracking number

E .Our technical support service member will be engaged for the coming set up job and guide you to run the machine smoothly . Technical support from us not only limited by email communication ,as well as the instant messages, video chatting .

we will create a service group for your side as whatsapp ,messengers, wechat etc.

F .Periodical following up for machine operation.

Question: how about the preparation work for running an ultrasonic welding machine ?

A, Ultrasonic welding machine comes with 220 Volt.(Please check your power supply, sometimes

B, transformer is needed)

C, An air compressor is needed

D, A hose which will connect the machine and air compressor.

Namely ,Ultrasonic welding machine a hose an air compressor

E,Tips about the hose:

Please make sure the air hose of welding machine first , If the hose of your air compressor different, please just add an adapter to join the two different hoses.

Hot Searches