- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1300*1090*1270mm

-

Weight:

-

2800 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

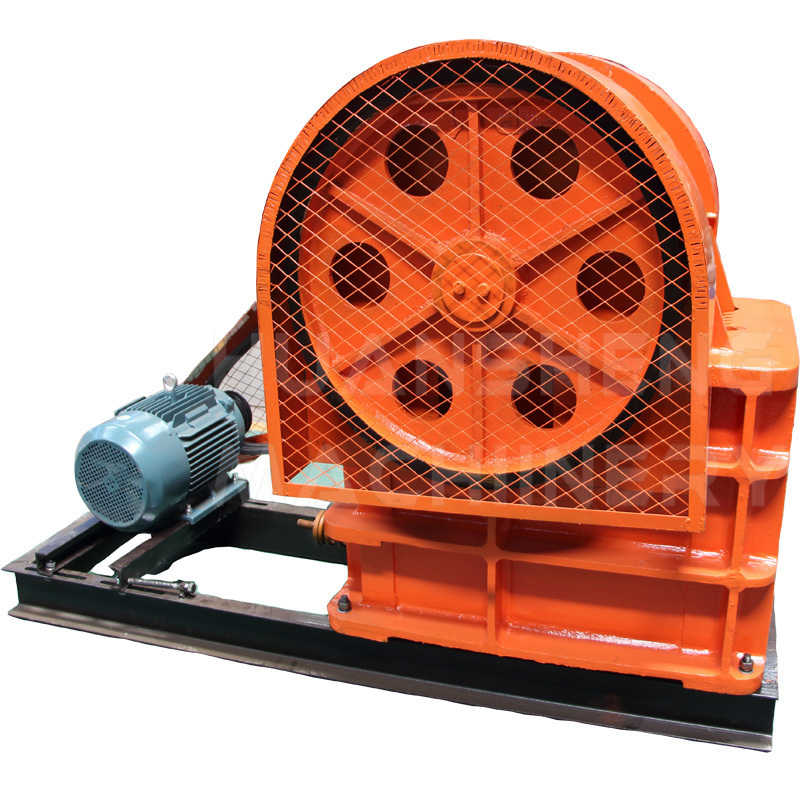

Jaw Crusher Machine

-

Keyword:

-

Quarry Rock Stone Jaw Crusher

-

Usage:

-

Crushing Work

-

Crusher type:

-

Jaw Crunsher

-

Raw material:

-

Stones Rocks Ores Coal

-

Color:

-

Customer Requirement

-

Advantage:

-

High Efficiency Low Energy

-

Quality:

-

High-Quality

-

After sale Service:

-

1 Year Warrenty

-

After-sales Service Provided:

-

Video Technical Support

Quick Details

-

Application:

-

Stone Mining Gold Ore Rock Limestone Gravel etc.

-

Place of Origin:

-

Henan

-

Brand Name:

-

HuanSheng

-

Dimension(L*W*H):

-

1300*1090*1270mm

-

Weight:

-

2800 KG

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Jaw Crusher Machine

-

Keyword:

-

Quarry Rock Stone Jaw Crusher

-

Usage:

-

Crushing Work

-

Crusher type:

-

Jaw Crunsher

-

Raw material:

-

Stones Rocks Ores Coal

-

Color:

-

Customer Requirement

-

Advantage:

-

High Efficiency Low Energy

-

Quality:

-

High-Quality

-

After sale Service:

-

1 Year Warrenty

-

After-sales Service Provided:

-

Video Technical Support

Products Description

Brief introduction

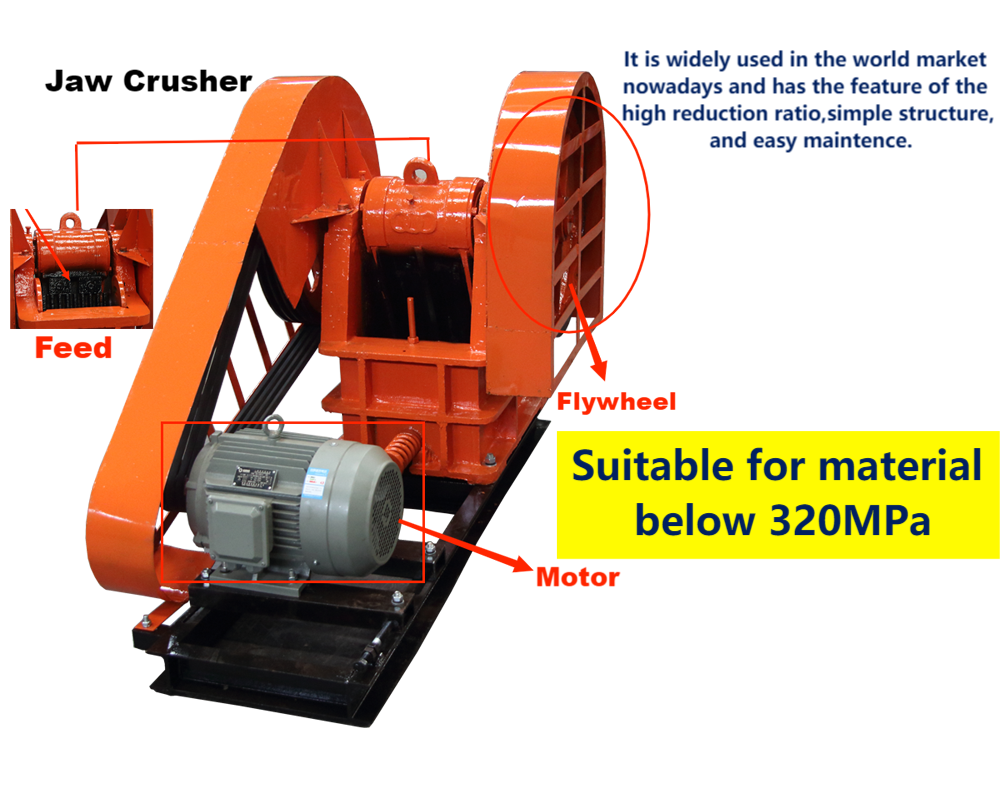

Jaw Crusher

has two types, primary and secondary crushers.The compressive resistance of the crushed materials is up to the 320MPa. The large and medium-sized crushers are the key products in our company and stand in the front of the industry in the aspects of design and production.

1) Simple structure, convenient in use and maintenance. Stable performance, low operation cost, high crushing ratio.

2) Crushing cavity depth and no blind spot, increasing the feeding ability and capacity.

3) High crushing ratio, uniform product size.

4) Gasket type discharging mouth adjusting device, reliable, convenient and the adjusting range is big,

increase the flexibility of the equipment.

5) Lubrication system safe and reliable, easy to parts replacement, small maintenance workload.

6) Simple structure, reliable operation, low operating costs.

Operating principle

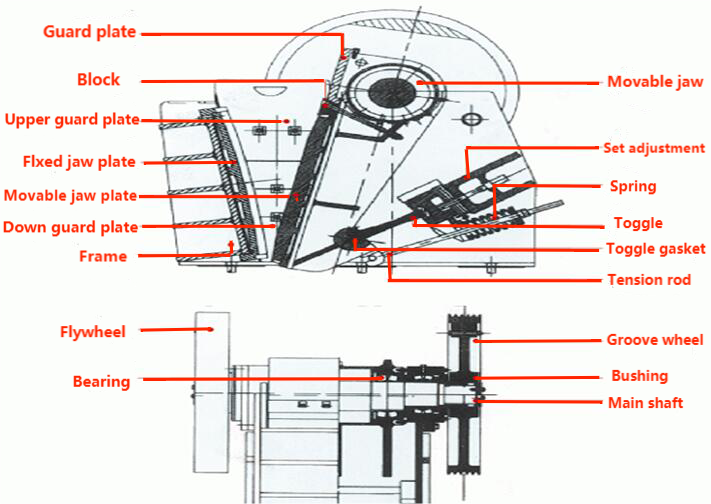

The motor drives the belt wheel, and makes movable jaw up and down by eccentric shaft, when the movable jaw down, the angle between the fixed jaw and movable jaw gets smaller, and the materials can be crushed to reach the crushing target, when the movable jaw rises, the angle between the fixed jaw and movable jaw becomes larger, the movable jaw plate leaves the fixed jaw plate under the function of drawbar and spring, and then the crushed materials are discharged from the lower outlet of the crushing cavity.

Product Parameters

|

Model:

PE. **

|

Max feed

size(mm)

|

Discharge

opening

range(mm)

|

Processing

capacity

(t/h)

|

Eccentic

shaft

speed(r/min)

|

Power

(kw)

|

Weight

(t)

|

Dimension

(mm)

|

|

150*250

|

150*250

|

10-40

|

1-3

|

250

|

5.5

|

0.8

|

720*660*850

|

|

200*300

|

200*300

|

15-50

|

2-6

|

260

|

7.5

|

1.2

|

910*750*990

|

|

200*350

|

200*350

|

18-70

|

3-10

|

260

|

11

|

1.5

|

1000*870*990

|

|

250*400

|

250*400

|

20-60

|

5-20

|

300

|

15

|

2.8

|

1300*1090*1270

|

|

400*600

|

400-600

|

40-100

|

16-60

|

275

|

30

|

7

|

1730*1730*1630

|

|

500*750

|

500*750

|

50-100

|

40-110

|

275

|

55

|

12

|

1980*2080*1870

|

|

600*750

|

600*750

|

150-200

|

80-240

|

275

|

55

|

15.8

|

2070*2000*1920

|

|

600*900II

|

600*900II

|

65-160

|

50-180

|

250

|

55

|

17

|

2190*2206*2300

|

|

750*1060

|

750*1060

|

80-140

|

110-320

|

250

|

110

|

29

|

2660*2430*2800

|

|

800*1060

|

800*1060

|

130-190

|

130-330

|

250

|

110

|

29.8

|

2710*2430*2800

|

|

830*1060

|

830*1060

|

160-220

|

150-226

|

250

|

110

|

30.7

|

2740*2430*2800

|

|

870*1060

|

870*1060

|

200-260

|

190-336

|

250

|

110

|

31.5

|

2810*2430*2800

|

|

900*1060

|

900*1060

|

230-290

|

230-390

|

250

|

110

|

33

|

2870*2420*2940

|

|

900*1200

|

900*1200

|

95-165

|

240-450

|

200

|

110

|

52

|

3380*2870*3300

|

|

1000*1200

|

1000*1200

|

195-265

|

315-500

|

200

|

110

|

55

|

3480*2876*3300

|

|

1200*1500

|

1200*1500

|

150-350

|

400-800

|

180

|

160

|

100.9

|

4200*3300*3500

|

|

1500*1800

|

1500*1800

|

220-350

|

500-1000

|

180

|

280

|

122

|

5160*3660*4248

|

|

1800*2100

|

1800*2100

|

300-400

|

600-1200

|

180

|

400

|

150.6

|

6210*4013*4716

|

Application

Jaw crusher is mainly used for medium-size crushing of various ores and large materials, which can carry out coarse and medium crushing operations of various ores, rocks and other materials with compressive strength not greater than 320MPa. It is the preferred equipment for crushing ore and coal gangue crusher and other ore materials. It is widely used in mining, smelting, building materials, roads, railways, water conservancy and chemical industries.

(A) The preparation of the jaw crusher before starting

1.Should carefully check whether the lubrication of the bearing is good, bearing elbow joint whether there is enough grease.

2.Should carefully check whether all fasteners are fully fastened.

3.Whether the protective device is good, found unsafe phenomenon, should be immediately eliminated.

1.Should carefully check whether the lubrication of the bearing is good, bearing elbow joint whether there is enough grease.

2.Should carefully check whether all fasteners are fully fastened.

3.Whether the protective device is good, found unsafe phenomenon, should be immediately eliminated.

(B) Starting of jaw crusher

1.After inspection and proof that the machine and transmission part are in normal condition, it can be started.

2.The machine can only be started without load.

3.After starting, if there is an abnormal situation, should immediately stop, to find out the cause of the hidden trouble, can start again.

1.After inspection and proof that the machine and transmission part are in normal condition, it can be started.

2.The machine can only be started without load.

3.After starting, if there is an abnormal situation, should immediately stop, to find out the cause of the hidden trouble, can start again.

(C) Maintenance and use of jaw crusher

1.The crusher can be fed after normal operation.

2.The material to be broken should be evenly added to the crushing chamber, and should avoid side feeding to prevent sudden load change or unilateral surge.

3.Under normal working conditions, the temperature rise of the bearing should not exceed 35 ° C, the maximum temperature should not exceed 70 ° C, otherwise it should be stopped immediately, identify the cause to be eliminated.

1.The crusher can be fed after normal operation.

2.The material to be broken should be evenly added to the crushing chamber, and should avoid side feeding to prevent sudden load change or unilateral surge.

3.Under normal working conditions, the temperature rise of the bearing should not exceed 35 ° C, the maximum temperature should not exceed 70 ° C, otherwise it should be stopped immediately, identify the cause to be eliminated.

(D) Lubrication of jaw crusher

1.Often pay attention to timely lubrication of the friction surface, can ensure the normal operation of the machine and extend the service life.

2.The grease used in this machine should be determined according to the use of location, temperature and other conditions, generally can be used calcium, sodium or calcium sodium grease.

3.The grease added to the bearing seat is 50-70% of its volume, and must be replaced every three months; When changing the oil, clean gasoline or kerosene must be used to clean the dirt in the bearing and bearing seat.

4.Grease must be added before the contact between the elbow plate and the elbow pad is started.

1.Often pay attention to timely lubrication of the friction surface, can ensure the normal operation of the machine and extend the service life.

2.The grease used in this machine should be determined according to the use of location, temperature and other conditions, generally can be used calcium, sodium or calcium sodium grease.

3.The grease added to the bearing seat is 50-70% of its volume, and must be replaced every three months; When changing the oil, clean gasoline or kerosene must be used to clean the dirt in the bearing and bearing seat.

4.Grease must be added before the contact between the elbow plate and the elbow pad is started.

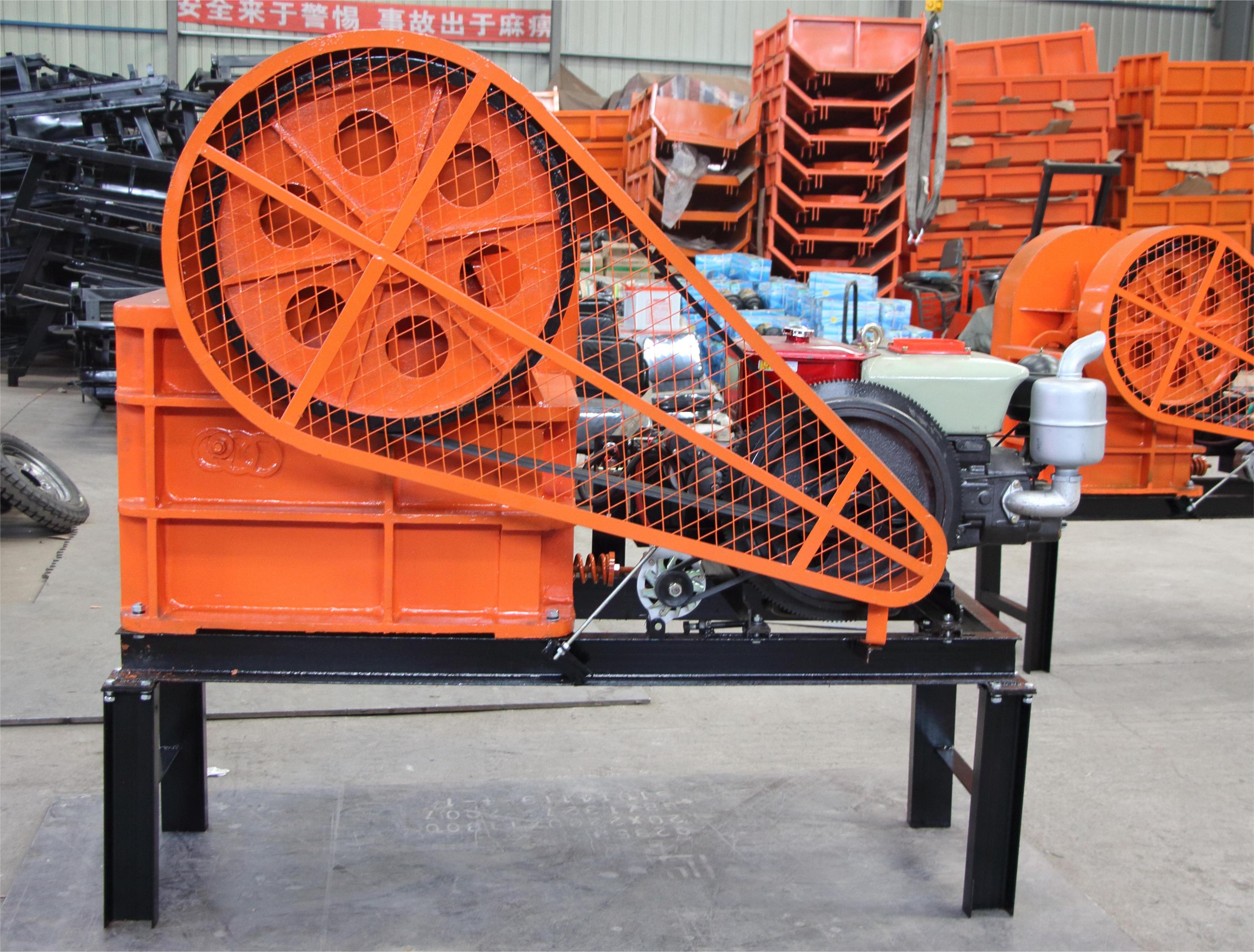

Customer Photos

Hot Searches