Brief Introduce:

It is applied to produce the printed double-lane or non-printed vest bags/ t shirt bags, using HDPE, LDPE roll film. It adopts PLC control,

double servo motors control and the touch screen actual display to finish the feeding, sealing, cutting, punching in one process, which can save man-power greatly and yield good economic result.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

chovyting

-

Weight:

-

4000 KG

-

Servo motor:

-

Yaskawa Japan

-

Inverter:

-

Yaskawa Japan

-

PLC:

-

PANASONC JAPAN

-

Touch screen:

-

Taiwan

-

Photocell:

-

SICK Germany

-

Switch and button:

-

IDEC Japan

-

Cylinder:

-

SHAKO Taiwan

-

Operation Language:

-

English/Russia/Arabic/Spanish /Chinese

-

Certification:

-

CE/SGS/ISO9001

Quick Details

-

Machine Type:

-

bag making machine

-

Bag Type:

-

GARBAGE BAG

-

Material:

-

PLA

-

Place of Origin:

-

China

-

Brand Name:

-

chovyting

-

Weight:

-

4000 KG

-

Servo motor:

-

Yaskawa Japan

-

Inverter:

-

Yaskawa Japan

-

PLC:

-

PANASONC JAPAN

-

Touch screen:

-

Taiwan

-

Photocell:

-

SICK Germany

-

Switch and button:

-

IDEC Japan

-

Cylinder:

-

SHAKO Taiwan

-

Operation Language:

-

English/Russia/Arabic/Spanish /Chinese

-

Certification:

-

CE/SGS/ISO9001

Product Description

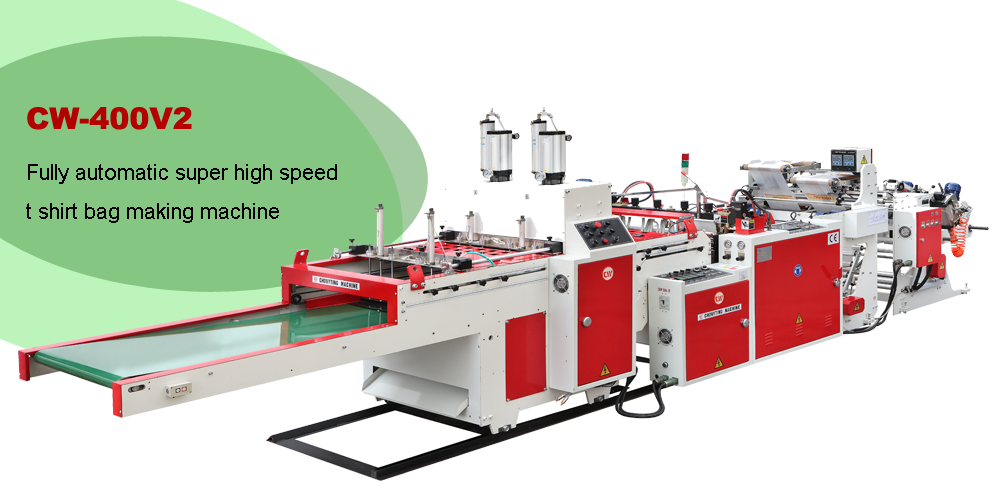

CW-400V2 Automatic High Speed Double Lane plastic Vest T-shirt Bag Making Machine (Hot sealing & hot cutting type)

|

Model

|

CW-500V

|

CW-400V2

|

CW-300V2+GS

|

|

Bag length

|

370-700mm

|

370-700mm

|

370-700mm

|

|

Width of bag making(Max.)

|

500mm

|

400mmx2Line

|

300mmx2Line

|

|

Width size of cutting knife

|

580mm

|

480mmx2Line

|

380mmx2Line

|

|

Speed of bag making(Max.)

|

250pcs

|

250pcsx2Line

|

220pcsx2Line

|

|

|

|

|

|

|

Line speed

|

125M/min

|

125M/min

|

100M/min

|

|

Total power

|

10KW

|

18.5KW

|

20KW

|

|

Machine weight

|

2800kg

|

3100kg

|

3800kg

|

|

Machine dimension

|

8000x1350x1800mm

|

8000x1850x1800mm

|

10000x2000x2000mm

|

Bag Samples

Details Images

Unwinder

1.unwinder adopts air cylinder automatic load design. max.diameter of the unwinder is 700mm.

2. Adopts AC frequency motor driving constant tension control,feeding speed is according to the producing speed.

3. Unwinding shaft adopts heavy-chainair shaft.

4. Unwinder part has the EPC and automatic tension

control.

5. Automatic stop design when rolls film finish or damage.

Automatic EPC control

1. This device special for this high speed model

2. When roll film feeding so fast that the film will move little

left and right, with this EPC device to be control the film

feeding corrected to the right position

3. This EPC system will enhance the productivity of

machine

4. One set EPC system to control two lines.

Sealing and cutting knife device

1. Sealing knife with 90 degree“turnover” device ,which easy to clean the knife ,which is better to keep the maintenance easy

2. The whole set of bags has design of swaying ,no paste between two bags mouth(ITALY DESIGN)

3. Fully automatic tacking of whole set and levelling stack design

2. The whole set of bags has design of swaying ,no paste between two bags mouth(ITALY DESIGN)

3. Fully automatic tacking of whole set and levelling stack design

Hydraulic air cylinder punch (photo have 3 punch as reference! CW-400V2 only two punch)

1. With 5 tons hydraulic air cylinder punch from Taiwan

2. the motor of clip for clamp the bag is Ac inverter motor control 1.5KW

3. Automatic collect bags and finish stack bags with double fold device

2. the motor of clip for clamp the bag is Ac inverter motor control 1.5KW

3. Automatic collect bags and finish stack bags with double fold device

Main Part

Packing & Loading

Certifications

About Us

CHOVYTING Machinery is a manufacturer specialized in the design and production of plastic bag machinery. it has adopted modern management methods such as 6S site management, PMC production management and international standard QC management, and adopted 3D mechanical design and IEC standard electrical 3D design to standardize production operations, so that to receive a higher rating from customer after use.

CHOVYTING always insists on providing customers with high quality and perfect products. Therefore, the actual process of each production step is strictly controlled, and the ISO-9000 quality system process is used to track and control and have passed the EU CE safety regulations.

CHOVYTING has more than 120 employees, 8 person for research and development, 9 person for sale, and 10 technical person for after sales that includes 5 person work in overseas all year round.

EXHIBITIONS

FAQ

1) Is your company a factory or a trading company?

We are a factory.

2) Where is your factory? How can i visit your company?

Our factory is located in Ruian, Zhejiang Province, China. It takes about 40 minutes from Shanghai to take the plane(5 hours for train). All our clients from home and abroad are warmly welcomed to visit us.

3) What is the suitable material for your machines?

PE, OPP, laminated material ,etc are suitable for our machines

4) What kind of machine do you have ?

We are specializing in manufacturing various of plastic bag making machine, laminated bag making machine, slitter, film blowing machine, etc...

5) How many years of your factory?

Our company is established since 1999.

6) What certificate of machine do you have?

CE, ISO 2008, more than 50 pieces Patent of machine

7) What about the development of your company?

Titled as “National Key and New Products” and Pass identification of the provincial new product, honored as” Patent Model Enterprise” as well.

8) How many exhibition do you take part in?

We start to took part in CHINAPLAS from 2008-2019,BANGLADESH, INSTANBUL, MOROCCO, MEXICO, EGYPT,

UZBEKIKSTAN, DUBAI E,THAILAND, INDIA EXBIHITION, K SHOW etc...

9) How many agent do your company have?

We have agents from Chile, Argentina, South Africa, Egypt, Israel, Lebanon, Syria etc...

10) How many workers of your company?

More than 150 workers.

Hot Searches