- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1500

-

Voltage:

-

3 phase 380v or customized

-

Current:

-

350A

-

Rated Capacity:

-

Depends

-

Rated Duty Cycle:

-

60%

-

Dimensions:

-

Depends

-

Use:

-

Welding

-

Welding Material:

-

Stainless

-

Type:

-

Automatic Control

-

Product name:

-

Longitudinal Seam Welding Machine

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Foshan zhongyong

-

Weight (KG):

-

1500

-

Voltage:

-

3 phase 380v or customized

-

Current:

-

350A

-

Rated Capacity:

-

Depends

-

Rated Duty Cycle:

-

60%

-

Dimensions:

-

Depends

-

Use:

-

Welding

-

Welding Material:

-

Stainless

-

Type:

-

Automatic Control

-

Product name:

-

Longitudinal Seam Welding Machine

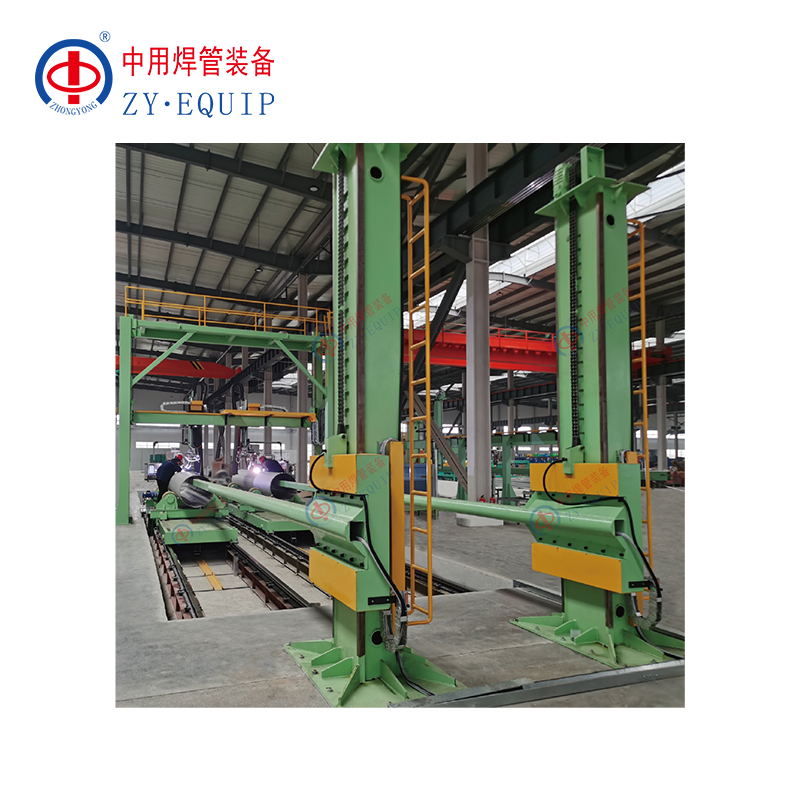

Product Parameters

|

Model

|

LM-6000

|

Model

|

BL6000

|

|

Max. Length of welding (mm)

|

6500

|

Welding tool

|

Double tool

|

|

Barrel diameter(mm)

|

219-3000

|

Welding method

|

Welding torch movement when longitudinal welding,

workpiece movement when circle welding

|

|

Welding mode

|

Plasma, TIG

|

Welding speed(m/min)

|

0-3

|

|

Input voltage

Welding mode

Welding type

|

Longtiudinal weldng, Circle welding (Outer welding)

|

Input voltage

|

3PH/4wires(380V±15%)

|

|

Tool type

|

Gantry type

|

Rated power(Kw)

|

72.5

|

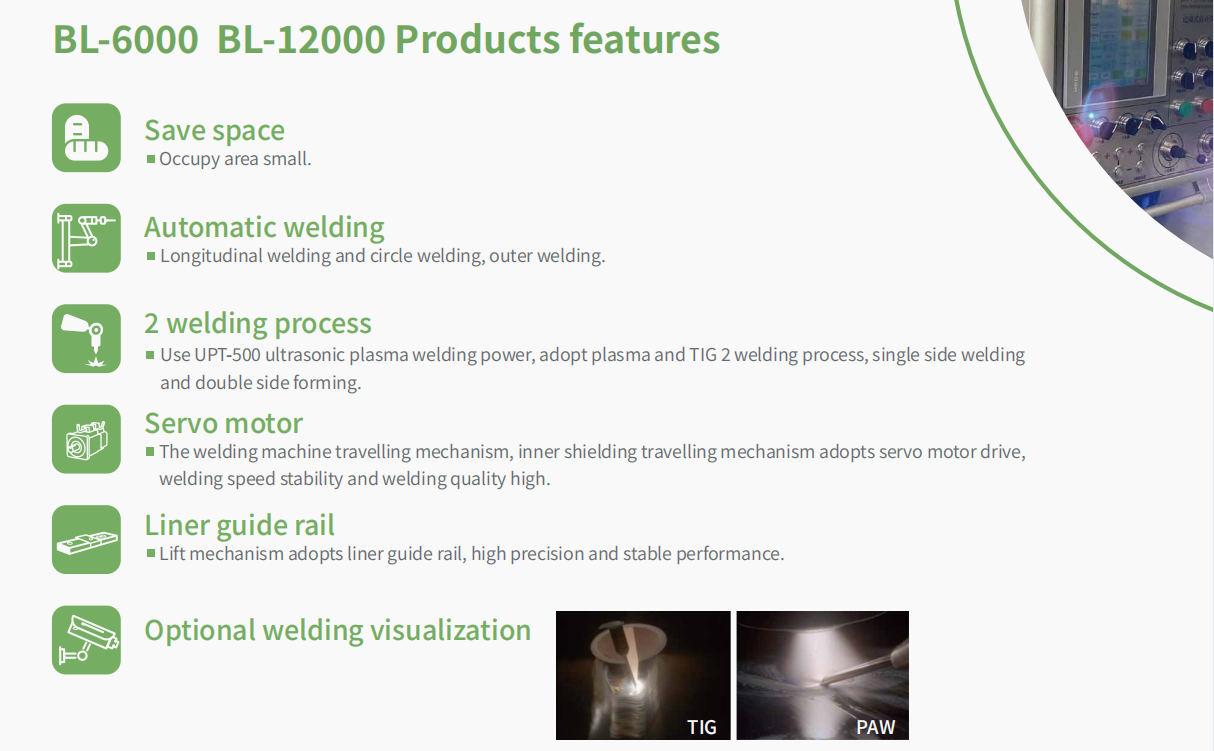

Products feature

Application field

Various products

Customer Case

Exhibition and Customer Visiting

FAQ

Q. What payment terms you can accept?

A: We can accept payment terms by T/T, D/P or L/C at sightetc.

Q: When is your company delivery time?

A: For small model of machine, our delivery time is within 2-3 months. It depends on the machine model and purchasing quantities.

Q:What about after-sales service from your company?

A: Firstly, our company has more than 10 engineers for installation and commissioning to meet our clients. Secondly, our intelligent control system will remote monitoring and diagnosis our tube mill production line, mean any problem caused will be showed clearly by HMI (human machine interface), then our engineer can guidance or solve problems by remote control.Finally, if visa is available, our engineers will fly to your site to solve any problem of tube mills.

Q:Are you a manufacturer or trading company?

A: We are a professional manufacturer with 15000 square meter independent and own workshop, focusing on the industrial intelligent welded tube mill production line

A: We can accept payment terms by T/T, D/P or L/C at sightetc.

Q: When is your company delivery time?

A: For small model of machine, our delivery time is within 2-3 months. It depends on the machine model and purchasing quantities.

Q:What about after-sales service from your company?

A: Firstly, our company has more than 10 engineers for installation and commissioning to meet our clients. Secondly, our intelligent control system will remote monitoring and diagnosis our tube mill production line, mean any problem caused will be showed clearly by HMI (human machine interface), then our engineer can guidance or solve problems by remote control.Finally, if visa is available, our engineers will fly to your site to solve any problem of tube mills.

Q:Are you a manufacturer or trading company?

A: We are a professional manufacturer with 15000 square meter independent and own workshop, focusing on the industrial intelligent welded tube mill production line

(

ASTM A269, ASTM 249, ASTM A312, EN10217 and DIN11850 etc.

), Online welding machine especial for stainless steel pipe plants and offline welding machine (for large OD stainless steel pipes from 219mm to 3500mm) etc. Since 2005. We have own

import and export license

right to deliver to customers by ourselves, no need middle trading company involved.

Q: What advantages for ZhongYong machine?

A:● We are the expert at the welding technology for stainless steel field more than 20 years, enjoy 80% market share at home and abroad.

● We have strong R&D, design team and obtained more than 100 products patents from the Patent Office in China.

●Unique electromagnetic control technology is applied in welding process with TIG welding machine to greatly improve welding speed and welding quality.

●Intelligent self-detection the whole tube mill production line before start making pipes.

● We have strictly production flow and precision tolerance limit for all spare parts, inspect each spare parts by professional staff and test equipment.

●In the making process of industrial pipes, we have the pickling and eddy current flow to improve the precision of tubes.

● All bed of machine must annealing by 24hours totally, to reduce deformation before processing

Q: What advantages for ZhongYong machine?

A:● We are the expert at the welding technology for stainless steel field more than 20 years, enjoy 80% market share at home and abroad.

● We have strong R&D, design team and obtained more than 100 products patents from the Patent Office in China.

●Unique electromagnetic control technology is applied in welding process with TIG welding machine to greatly improve welding speed and welding quality.

●Intelligent self-detection the whole tube mill production line before start making pipes.

● We have strictly production flow and precision tolerance limit for all spare parts, inspect each spare parts by professional staff and test equipment.

●In the making process of industrial pipes, we have the pickling and eddy current flow to improve the precision of tubes.

● All bed of machine must annealing by 24hours totally, to reduce deformation before processing

Exhibition

Hot Searches