- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V

-

Power:

-

7.5KW

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

8000*1500*1500

-

Year:

-

2024

-

Product name:

-

Coconut processing machine

-

Application:

-

Fruit Vegetable

-

Function:

-

Multifunctional

-

After-sales Service Provided:

-

Online Support

-

Advantage:

-

Low Consumption High Efficiency

-

Processing Types:

-

Fruits Process Equpiment

-

Capacity:

-

500-800kg/h

-

Color:

-

Silver

-

Material:

-

Stainless Steel SUS304/316

-

Final product:

-

Fruit Pulp

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Beyond

-

Type:

-

Fruit processing machine

-

Voltage:

-

220V/380V/415V

-

Power:

-

7.5KW

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

8000*1500*1500

-

Year:

-

2024

-

Product name:

-

Coconut processing machine

-

Application:

-

Fruit Vegetable

-

Function:

-

Multifunctional

-

After-sales Service Provided:

-

Online Support

-

Advantage:

-

Low Consumption High Efficiency

-

Processing Types:

-

Fruits Process Equpiment

-

Capacity:

-

500-800kg/h

-

Color:

-

Silver

-

Material:

-

Stainless Steel SUS304/316

-

Final product:

-

Fruit Pulp

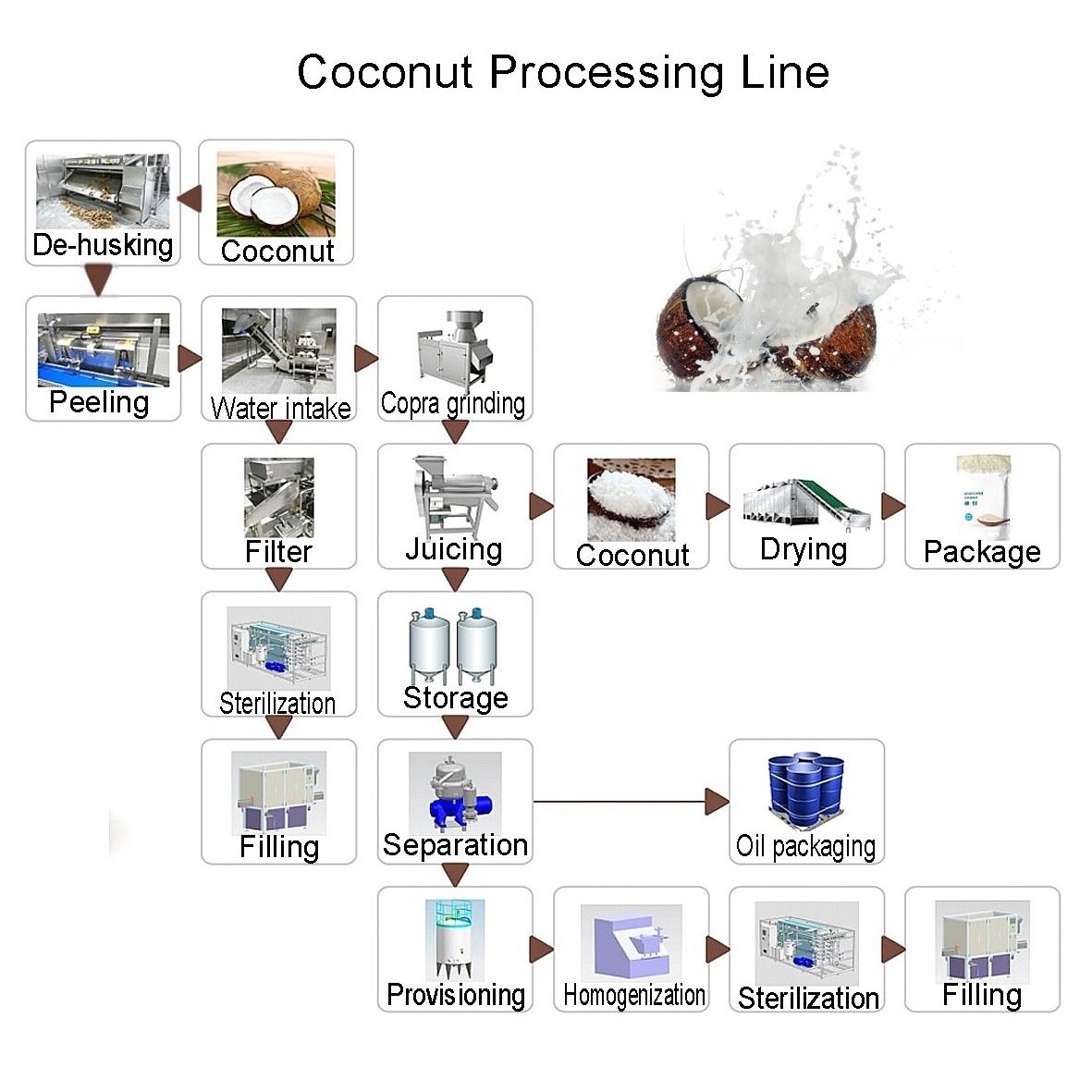

Coconut processing machine coconut processing plant cost coconut processing machinery export from china

Coconut processing machine is an equipment used to process coconuts and their products. It can help peel coconuts out of their shells and perform processes such as shelling, peeling, and flower removal to obtain coconut meat and coconut water. In addition, coconut processing machines can also be used to produce coconut by-products such as coconut oil, coconut powder, and coconut milk.

Here are some common coconut processing machines:

1.

Coconut peeler

: used to peel the outer shell of coconuts, usually achieved by mechanical force or pressure.

2.

Coconut shell remover

: used to completely remove the shell of coconuts for further processing of coconut meat and coconut water.

3.

Coconut cutting machine

: used to cut open coconuts for easier removal of coconut meat and coconut water.

4.

Coconut grinder

: used to grind coconut meat into a delicate paste for extracting coconut oil or making coconut milk.

5.

Coconut crusher

: used to crush coconut meat or dried coconut fruits into powder to make coconut powder.

6.

Coconut water extractor

: used to extract fresh coconut water from coconuts.

7.

Coconut oil extractor

: used to extract coconut oil from coconut meat, usually using pressing or solvent extraction methods.

These coconut processing machines can choose suitable models and capacities based on different processing scales and requirements. The use of coconut processing machines can improve production efficiency, reduce manual labor, improve product quality, and is widely used in the coconut planting and processing industry.

Characteristics of coconut processing line

The highlights of coconut processing line mainly include the following aspects:

1.

High degree of automation

: The coconut processing line adopts advanced automation equipment and technology, which can achieve fully automated operations from coconut processing to finished product production. This not only improves production efficiency, but also reduces labor costs and intensity.

2.

Multifunctionality

: Coconut processing lines can be applied to the processing of various coconut products, such as coconut oil, coconut powder, coconut water, etc. It can meet the processing needs of different products and provide diversified coconut products.

3.

High quality products

: The coconut processing line uses high-quality materials and advanced technology to ensure the production of high-quality coconut products. It can accurately process and separate coconuts, preserving their nutritional and flavor characteristics.

4.

Energy conservation and environmental protection

: Coconut processing lines pay attention to energy conservation and environmental protection in their design and operation. It adopts efficient equipment and systems to reduce energy consumption and waste emissions. At the same time, it can also comprehensively utilize the remaining coconuts, reducing resource waste.

5.

Flexible and adjustable

: Coconut processing lines have flexible production capacity and adjustable performance. It can adjust and expand the production line according to market demand, adapting to production requirements of different scales and volumes.

In summary, the highlight of coconut processing lines lies in their high degree of automation, multifunctionality, high-quality products, energy conservation, environmental protection, and flexibility, making the coconut processing process more efficient, reliable, and sustainable.

PARAMETER

| Raw Material | Coconut shell and coconut meat |

| End products | coconut water and milk, coconut cream, coconut oil |

| End Package | Aseptic bags in drums, bottles, tin cans, cartons |

| Processing products | UHT water and milk |

End Products and Package of Coconut Processing Line

--Concentrate Coconut water filled into aseptic bags(5kg,220kg or 1000kg)

--Single strength coconut water(Non-concentrated coconut water)filled into tin cans,bottles or asptic bags.

--Coconut milk/cream filled into aseptic bags,tin cans or bottles.

--Desiccated Coconut filled into poly bags,jars or pouches.

--Virgin Coconut Oil(VCO)filled into bottles or barrels.

Single Strength Coconut water

is a refreshing and cooling drink. Its sodium and potassium content makes it an ideal drink for rehydration. In a healthy, undamaged coconut, the water is even sterile. Fresh coconut after dehusking and deshelling, then use one needle to pierce one hole on the coconut to extract coconut water. After extraction, coconut water is filtered. Filtration can be done using a double cloth filter. This is especially important for mature coconut water, as dry husk fibres and dirt from the shell of mature nuts can easily get into the coconut water during extraction. After filtration, the coconut water is quickly cooled to retard any deterioration reactions. Then, it is sent for separation, homogenizing, degassing, subsequent pasteurization and aseptic packaging.

If coconut water is extracted at a location away from the aseptic packaging site, the filtered coconut water can be packed into food grade plastic bags, quickly cooled and transported to downstream processing. The single strength coconut water content is 92%-95% and soluble solids is about 12 brix.

Concentrated coconut water

: Concentrated coconut water is about 60-65 brix and water content is about 35%-40%. Fresh coconut water after extracting, filtering, cooled to 10 ℃ and storing into double layers insulation tanks. Then the low-temperature coconut water will be prepasteurization and separation. Then, it goes into a multiple-effect evaporation stage to increase °Brix levels. Usually, the product is concentrated to 60-65 °Brix and packed into 200 kg plastic bags in drums for bulk transportation under ambient conditions. It is recommended that the concentrate coconut water will be stored at below zero temperature for 2 years.

Coconut milk/cream

: Coconut milk and cream are produced from 10-13 months old mature coconuts when the kernel is hard and thick. They are natural oil-in-water emulsions extracted from the mature coconut kernel. The difference between coconut milk and cream is the amount of fat. The fat content of the coconut milk is 5%-20%, whereas coconut cream reaches to 20%-50%. To extract coconut milk for industrial manufacturing purposes, mature coconuts go through deshelling and paring. Pieces of kernels are then sent into industrial-scale cutters and grinders. Next, grated coconut kernel then goes into a series of screw extractors to extract coconut milk. The residual kernel from this first press is then mixed with water before it is pressed again to increase extraction yield. After extraction, coconut milk is filtered to remove large contaminants. It can then be standardized to a pre-determined level of fat and blended with other ingredients. Finally, coconut milk is homogenized, degassed, pasteurized and aseptically filled into aseptic bags or small package like bottles or tin cans.

Coconut oil : Coconut oil is one of the main products traditionally derived from the coconut kernel. Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used. The oil extraction technology, which starts with copra as the raw material, is commonly known as the dry process. While the method that uses fresh coconuts as starting material is generally called the fresh-wet or fresh-dry process. Based on different separation methods, coconut oil can be classified into two types – RBD coconut oil and virgin coconut oil (VCO). The former is refined, bleached and deodorized (RBD) from dry extraction, while the latter is produced by fresh-wet and fresh-dry extractions.

The information technology of coconut milk processing line is mainly reflected in the following aspects:

1 Automation Control System : The coconut milk production line adopts advanced PLC (Programmable Logic Controller) or DCS (Distributed Control System) for automation control, achieving precise regulation and real-time monitoring from raw material reception, coconut meat extraction, grinding and pulping, centrifugal separation, standardized blending, sterilization treatment to filling and sealing.

2. Data collection system : Through various sensors and intelligent instruments installed on the production line, real-time data including raw material quality, production process parameters (such as temperature, pressure, flow rate), equipment operation status, and product quality indicators are collected to ensure efficient and stable production.

3. MES Manufacturing Execution System : Utilizing the MES system to track and manage the entire process of coconut milk production, including material traceability, process monitoring, quality inspection, and yield statistical analysis, helps optimize production scheduling, reduce waste, and quickly respond to quality issues, improving product quality management level.

4. ERP Enterprise Resource Planning System : The ERP system integrates all resource information involved in the coconut milk production process, including raw material procurement, inventory management, production planning, cost accounting, sales forecasting, etc., effectively improving the supply chain management and decision-making efficiency of the enterprise.

5. Application of Internet of Things Technology : • By using Internet of Things technology on coconut milk processing lines, equipment interconnection can be achieved. RFID (Radio Frequency Identification) can be used for material tracking, remote monitoring and data analysis can be carried out through cloud computing platforms, early warning of possible faults, reducing downtime, and improving equipment utilization.

6. Food Safety Traceability System : Establish a comprehensive food safety traceability system using information technology, recording detailed information on each bottle of coconut milk from raw material cultivation, harvesting, processing to the final product. Once a food safety issue occurs, it can quickly locate the source of the problem and protect consumer rights.

7. Big data analysis and optimization : • Collect and analyze massive production data, use artificial intelligence algorithms to deeply mine and learn the production process, continuously optimize production process parameters, reduce costs, improve product quality, and provide scientific basis for continuous improvement.

Pre sales services

After-sale service

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.