- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customzied

-

Dimension(L*W*H):

-

Customzied

-

Weight:

-

500 KG

-

Machinery Function:

-

Cocoa Butter Grinding Machine

-

Output product name:

-

Cocoa Butter Grinding Machine

-

Material:

-

Stainless Steel

-

Type:

-

butter processing machine

Quick Details

-

Brand Name:

-

LONGER

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220/380v, 5.5kw,380V/220V

-

Power:

-

Customzied

-

Dimension(L*W*H):

-

Customzied

-

Weight:

-

500 KG

-

Machinery Function:

-

Cocoa Butter Grinding Machine

-

Output product name:

-

Cocoa Butter Grinding Machine

-

Material:

-

Stainless Steel

-

Type:

-

butter processing machine

Walnut Butter/Cocoa Butter Grinding Machine/Date Palm Grinder

Email: maggie @longerinc.com Whatsapp/ Tel/ Wechat: 0086 185 6993 3368

| Application range of coffee,cocoa bean grinding machine: |

Application range of coffee,cocoa bean grinding machine:

1, the food industry: aloe, pollen, pineapple, hawthorn, carrot, juice, fruit juice, jam, fruit juice beverage, ice cream, food stuffing, red bean paste, coconut, lotus seed paste, cream, corn, bean paste, soy milk, peanut milk, peanut butter, sesame, malt flavor, dairy products, beverage,, chicken bone, seasoning, emulsifying pigskin, pet food.

2, the chemical industry: paint, pigment, dye, paint, lubricating oil, grease, asphalt emulsion adhesive, etc.;

3, daily chemical industry: toothpaste, detergent, shampoo, shoe polish, cosmetics;

4, the pharmaceutical industry: all kinds of syrup, nutrition, medicine, pharmacy paste, biological products, health products, cod-liver oil, pollen, royal jelly, vaccine, ointment, oral liquid, injection, intravenous fluid, emulsion and so on;

5, the construction industry: all kinds of internal and external wall coating, waterproof anti-corrosion coating etc.

| Technical Parameters |

| Model | fineness | Capacity | Power | Dimension | Weight |

| LG-JMS-50 | 2-50um | 0.005-0.03t/h | 1.1/1.5kw | 530*260*580mm | 70kg |

| LG-JMS-80 | 0.07-0.5t/h | 4kw | 680*380*930mm | 210kg | |

| LG-JMS-110 | 0.3-1.2t/h | 7.5kw | 750*450*1000mm | 280kg | |

| LG-JMS-130 | 0.4-2.0t/h | 11/15kw | 990*450*1100mm | 400kg | |

| LG-JMS-180 | 0.8-6.0t/h | 18.5/22kw | 1000*480*1150mm | 450kg | |

| LG-JMS-240 | 4.0-12t/h | 37/45kw | 1330*650*1300mm | 1000kg | |

| LG-JMS-300 | 6.0-25t/h | 75/90kw | 1450*630*1420mm | 1600kg |

| Working Principle |

The cocoa and peanut grinder is a device for fine grinding and treatment of fluid and semi-fluid materials. According to the requirements of the materials to be processed, the material can be subjected to powerful shearing by high-speed relative movement of fixed teeth and rotating teeth. Shear force, friction force and high frequency vibration are to be applied. This machine has ultrafine pulverization, dispersion, emulsification, homogenization and mixing equivalent energy.

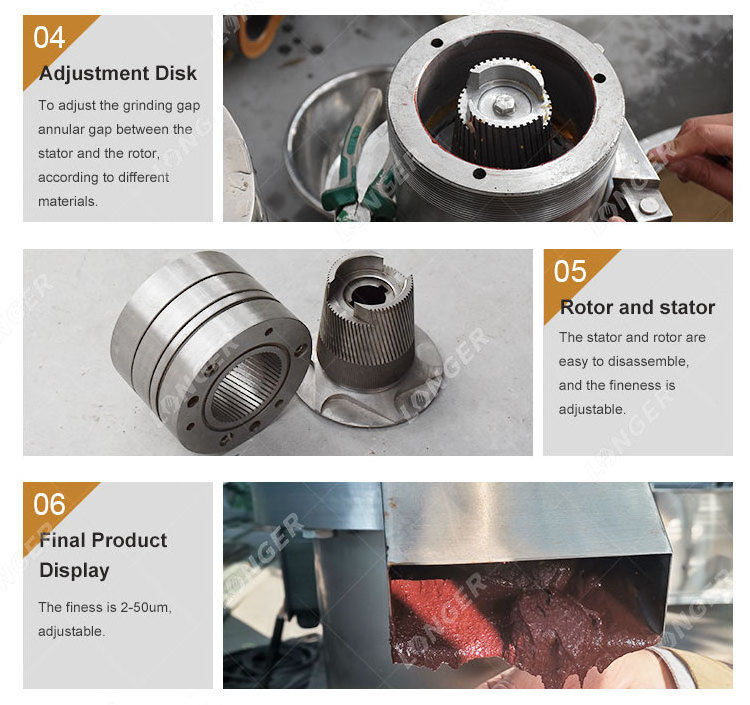

| Machine Detail Dispaly |

| Install and Operation: |

1. The equipment is installed horizontally on a flat concrete foundation and fixed with anchor screws (not fixed according to the working condition of the colloid mill).

2. Check if the fastening screws are tightened (the rotor center screw is M12 left-hand screw).

3. Before using the colloid mill, use a special wrench to turn the rotor to check whether it is in contact with the stator, and if there is any jam, if it is not allowed to start the machine.

4. Check and connect the power cable (three-phase AC, voltage 380 volts, body protection ground) and note that the direction of rotation of the rotor should be the same as the arrow on the base.

5. Turn on the cooling water and pay attention to the water inlet and outlet signs.

6. When starting the motor, first jog the switch to check for noise and vibration. If the situation is not normal, stop it immediately and try again after troubleshooting.

| FAQ |

|

Q1. Which Parts can be changed 304 stainless steel? |

A1: The hopper, discharge part and outsourcing part. |

| Q2. what is the material? |

A2: Overall frame is carbon steel , outsourced is 202 stainless steel, stator is 420. |

| Q3. What is the voltage? |

A3: The equipment is powered by three-phase power. Only models below LGJMS-80 can be changed to single-phase power; all types of equipment can change voltage and frequency. |

|

Q4. Can I change the material of the stator and rotor? |

A4: The material texture is soft. If the acid content is high, the 304 material can be used. It is generally not recommended to change the rotor material. |

| Q5. How is the discharge temperature? |

A5: When grinding nuts, beans, long-term work monomer colloid milling temperature is 70-80 degrees Celsius, double colloid milling temperature is 100 degrees Celsius. |

| Q6. How to clean the machine? |

A6: Clean the machine with water, dry it with a high-pressure air gun, keep it dry in a dry place, check the machine regularly and apply oil on the machine. |

| Q7. How to grind repeatedly? |

A7: The colloid mill grinding nozzle can be changed to the circulating return pipe. The circulating return pipe is provided with a three-way valve. It can be discharged or cycled as needed. All models can be changed. The 80 and 110 return pipes are 25mm in diameter, 130/. 180 return pipe diameter 32mm. |

| Q8. How often to replace the fixed rotor? |

A8: The nut material is generally grind 100-200T, the rotor must be replaced, for other materials, according to the hardness of the material and equipment using frequency. |

| Q9. How to use the cooling nozzles? |

A9: The machine should be used cooling nozzles first, then start to grind material. |

|

More Date Grinding Machines |