- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

mould

-

Dimension(L*W*H):

-

1500X800X1500mm

-

Weight:

-

300

-

Applicable Industries:

-

candle factory

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Output:

-

2-5time/hour

-

mould numbe:

-

120pcs/240pcs/360pcs

-

Certification:

-

CE certificate

-

Product name:

-

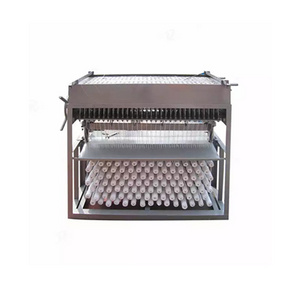

Semi-automatic Candle Making Machine

-

Material:

-

Staniless Steel

-

Candle Size:

-

Diameter Customized . Length

-

Name:

-

Poring candle machine

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

HD

-

Production Capacity:

-

95%

-

Core Components:

-

mould

-

Dimension(L*W*H):

-

1500X800X1500mm

-

Weight:

-

300

-

Applicable Industries:

-

candle factory

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Output:

-

2-5time/hour

-

mould numbe:

-

120pcs/240pcs/360pcs

-

Certification:

-

CE certificate

-

Product name:

-

Semi-automatic Candle Making Machine

-

Material:

-

Staniless Steel

-

Candle Size:

-

Diameter Customized . Length

-

Name:

-

Poring candle machine

Manual Pouring machine operation steps as follows:

First, Thread the wick through the hole of each mould.

Pour the liquid wax into the mould of the machine until the liquid wax full of mould trough. Second, some minutes later, The cold water(This is cycle---enter into one pipeline and out of another pipeline. ) (Picture 1) will make the liquid wax cooling and shaping. Finally, the worker should turn the handle (Picture 2) which is beside of the machine. The taper candle will be pushed out of the mould.

We have sold our machines to many countries ,such as USA,Spain ,Mexico,Argents and so on.

We are exhibitor of carton fair and we will attend carton fair twice a year.You can see the pictures

of our booth.

CE certification and ISO9001 for our machine