- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

EG-T009

-

Product name:

-

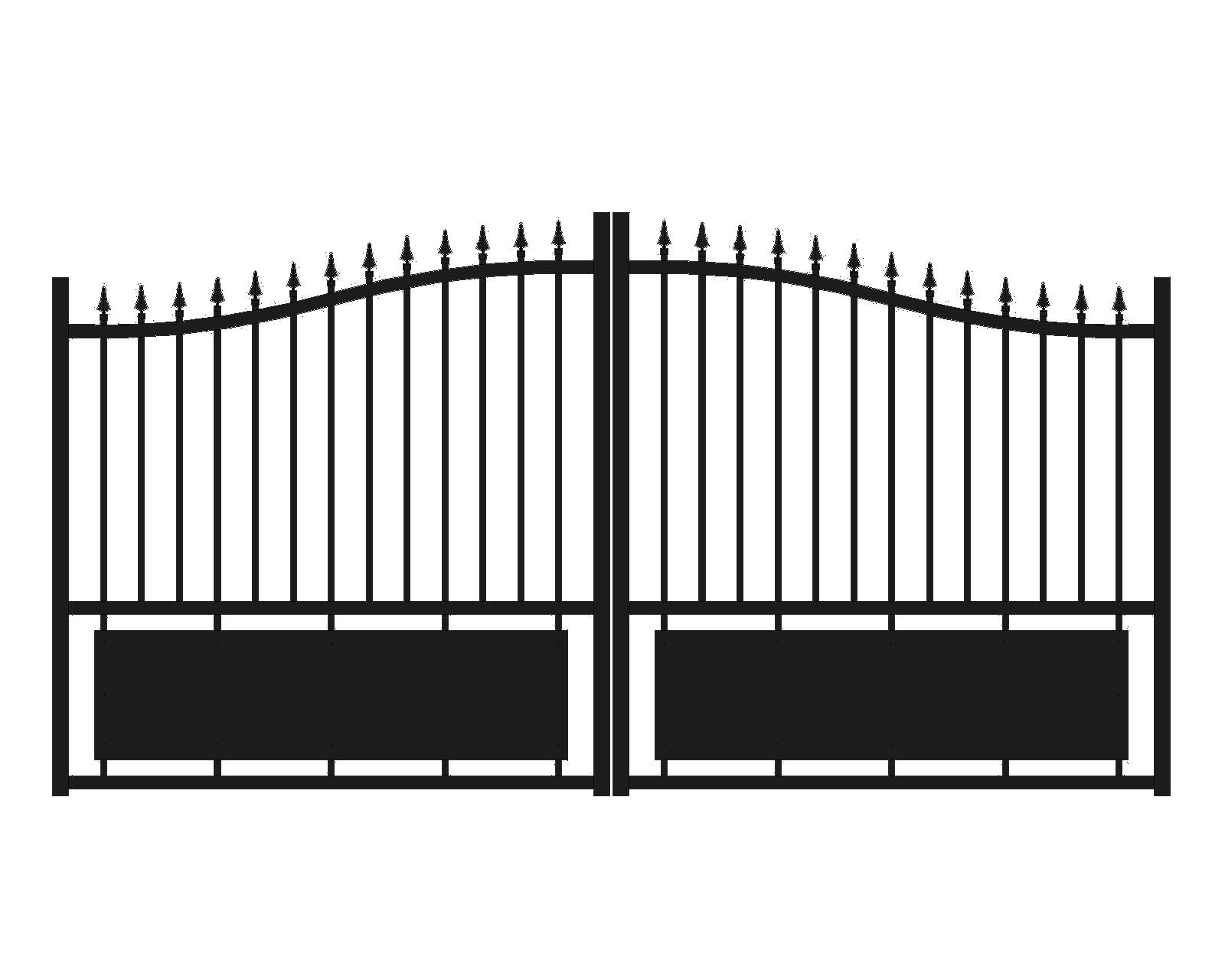

factory price powder coating black aluminum fence gate designs

-

Surface treatment:

-

Powder Coating

-

Material:

-

Aluminum 6063 and 6061

-

picket:

-

19*19*1.2mm

-

Height:

-

4'/4'/6' high

-

picket spacing:

-

98mm side to side

-

Length:

-

12' /10'/ custom

-

frame:

-

50*50

-

bottom rail:

-

50*100

-

hinge:

-

yes

Quick Details

-

Frame Material:

-

Metal

-

Feature:

-

Easily Assembled, Waterproof

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

EG-T009

-

Product name:

-

factory price powder coating black aluminum fence gate designs

-

Surface treatment:

-

Powder Coating

-

Material:

-

Aluminum 6063 and 6061

-

picket:

-

19*19*1.2mm

-

Height:

-

4'/4'/6' high

-

picket spacing:

-

98mm side to side

-

Length:

-

12' /10'/ custom

-

frame:

-

50*50

-

bottom rail:

-

50*100

-

hinge:

-

yes

| Product name | Aluminum fence driveway/walkway gate |

| Size | H1800mm x L2400mm / H1800mm x L3000mm / customized |

| Rail size | 38mm x 25mm / 38mm x 38mm / 40mm x 40mm |

| Picket size | 16mm x 16mm /19mm x 19mm / 25mm x 25mm |

| Post size | 50mm*50mm /75mmx75mm |

| Picket space | 90mm |

| Material | 6063-T5 aluminum |

| Finishing | Powder coating |

| Color | White / black/ grey , RAL color available |

| Warranty | Lifetime for material, 10 years for powder coating |

1: CUTTING:

Our cutting machine hasTwo double head saw , 1 CNC cutting machine , 2 plate cutting machine.

2: PUNCHING:

has 1 * 1.8m long punching machine , 8* 20T punching machines 3*100T punching machines, can provide all kinds of holes on differently materials

3: DRILLING:

has 3 row drilling machine

4: WELDING:

has 6 aluminum welding machines , 5 steel welding machines , and one welding robot.

5: POWER COATING PRETREATMENT:

Before power coating, the aluminium materails will be pretreated by re moving oil, water cleaning, chromating..

6: POWER COATING:

The power coating, we use Axalta Coating Systems.

1 : Every piece (fence/railing) was packed with thermal shinkage film or plastics bag and carton borad.

2: Stacked together on the steel pallet and bined with packing tape.

3: The whole pallet was wrapped with film again.

4: Post was filled into strong carton box and stacked on the pallets.

5: Post pallets were wraped with film totally.

6 : Then they were carfully lifted with fork truck into container.