- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

150*120*130

-

Weight (KG):

-

1650

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

busbar processing machine

-

Model:

-

BM603-S-8P

-

After Warranty Service:

-

Online support

Quick Details

-

Max. Thickness (mm):

-

15 mm

-

Max. Width (mm):

-

160 mm

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

150*120*130

-

Weight (KG):

-

1650

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

product name:

-

busbar processing machine

-

Model:

-

BM603-S-8P

-

After Warranty Service:

-

Online support

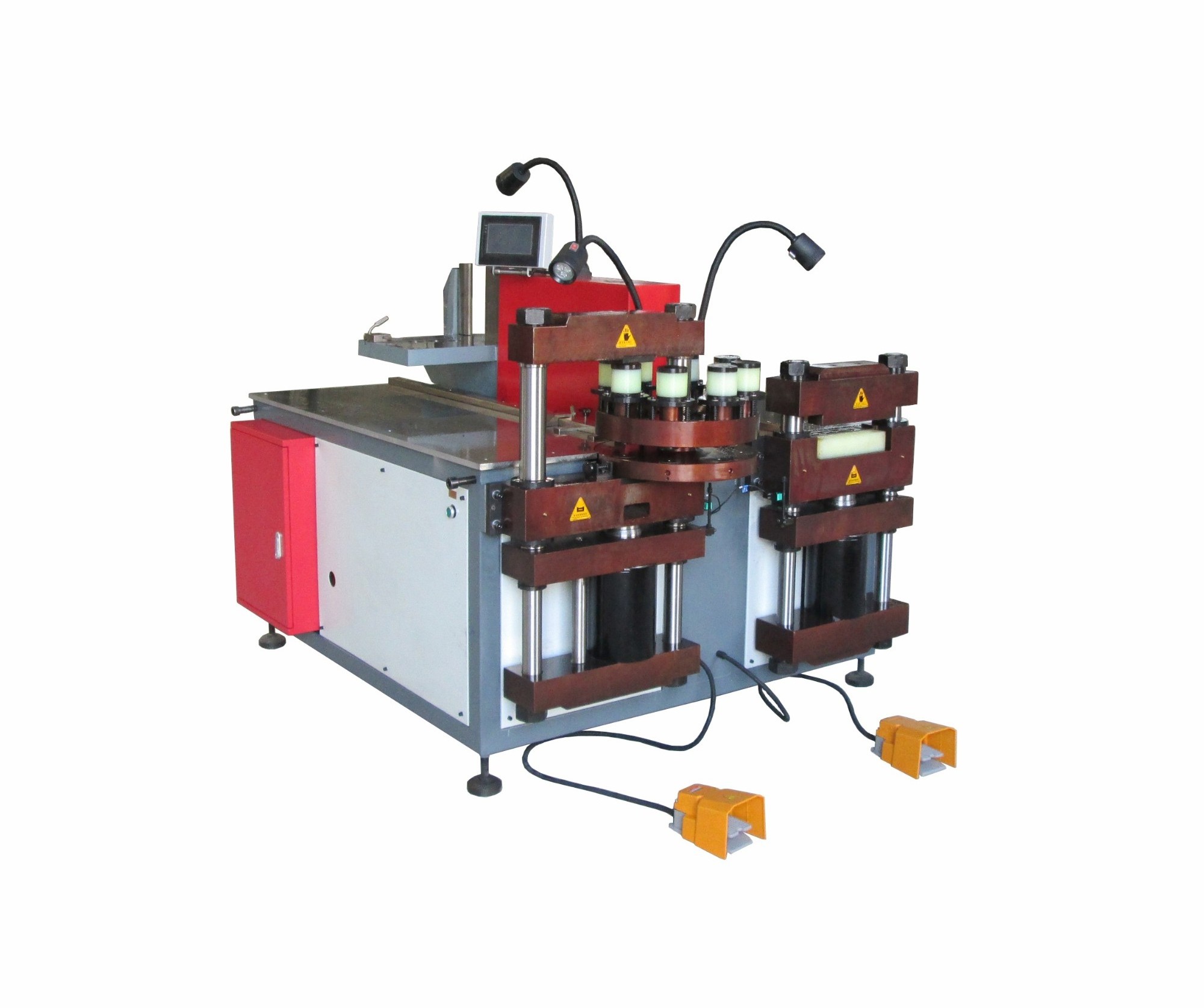

multi-function Busbar processing machine

Model:

BM603-S-8P

Part 1:Main features :

1. This model used turret for punching work, Max. 8 sets of tooling (punching or embossing) can be stored in.

The guide sleeve and punching head slide against each other, which ensure good coaxiality and long life of toolings.

- The Dual Column copper sleeve friction Vice structure, which is of unique design, avoids distortion and ensures long life.

- simultaneous work of the three work stations and avoids the interference of each other.

6. The machine use high quality hydraulic system and imported hydraulic elements, Φ10mm big drift diameter solenoid valve, which is of low noise and stable performance.

Part 2:Main parameters

|

Work table dimension(mm) |

Machine weight(kg) |

Motor QTY |

Total Motor Power(KW) |

Work voltage |

Hydraulic Station QTY*SPEC.(Mpa) |

|

1 P st P :1500*1200 2 P nd P :840*370 |

1560 |

3+1 |

11.37 |

380V |

3*31.5 |

|

Control method: PLC+ Bending angle NC control |

|||||

|

Punching unit |

|||||

|

Item |

Unit |

Material |

Thickness(mm) |

Max. Diameter of Punching hole |

|

|

Punching capacity |

mm |

Copper/Aluminum |

15/15 |

25mm |

|

|

Max. Punching Force |

KN |

500 |

|||

|

Cylinder stroke |

mm |

50 |

|||

|

Cutting unit |

|||||

|

Item |

Unit |

Material |

Max. Thickness(mm) |

Max. Width |

|

|

Cutting capacity |

mm |

Copper/Aluminum |

15/15 |

160/160 |

|

|

Max. cutting Force |

KN |

500 |

|||

|

Cylinder stroke |

mm |

50 |

|||

|

Bending unit (Bending angle NC control) |

|||||

|

Item |

Unit |

Material |

Max. Thickness(mm) |

Max. Width |

Bending accuracy |

|

Bending capacity |

mm |

Copper/Aluminum |

15/15 |

160/160 |

+/- 0.5º |

|

Max. bending Force |

KN |

350 |

|||

|

Cylinder stroke |

mm |

240 |

|||

|

The max. processing dimension when doing vertical bending: width*thickness=100mm*10mm |

|||||

Part 3: General description of each work unit

Punch Unit

It can finish round hole punch, oblong hole punch, square hole punch and embossing etc through change of die.

Shear Unit

Two kinds of shearing method for your choice.-punching shear and single shearing.

For punching shear the verticality of the end surface is guaranteed, no deformation of workpiece and the end surface is bright and good appearance. But it wastes the raw material a little.

For single shear, there is a little bevel angle on the work piece but it wastes no raw material.

Bend Unit

Plain (horizontal) bending, vertical bending ,elbow pipe bending, connecting terminal and copper busbar bending etc can be carried out via changing of die. The die is simple and easy to change.

Part 4: Accompanying standard toolings:

- Punching

Round and oblong holes total 8 sets, size as per customer’s requirement

- Vertical bending 1 set

- Horizontal bending 1 set

- Embossing 1 set

- Cutting 1 set

Note: The connecting terminal die is not included in the standard tooling, if it is needed, pls inform us cable sizes

1. Sample Order Accepted .

2. Stable Stock & Fast Delivery .

3. Professional Factory Manufacturing One Year Warranty .

4. Provide more Reliable, more Maturity and more Economy Solutions.

5. Professional Modernization Team with Experienced and Skilled Engineers .

6. Provide you with best Product quality, best Project quality and best Service quality.

Multi function busbar processing machine | busbar processing machine | BM503-S-8P Multi function busb