- Product Details

- {{item.text}}

Quick Details

-

Capacity:

-

3-10mold/min

-

Power:

-

100W

-

Pressure:

-

0.07-0.97MPa

-

Dimension:

-

450*450*900mm

-

Automatic grade:

-

Semi-automatic

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Weight (KG):

-

200

-

Material:

-

SUS304

-

Capacity:

-

3-10mold/min

-

Power:

-

100W

-

Pressure:

-

0.07-0.97MPa

-

Dimension:

-

450*450*900mm

-

Automatic grade:

-

Semi-automatic

Product Description

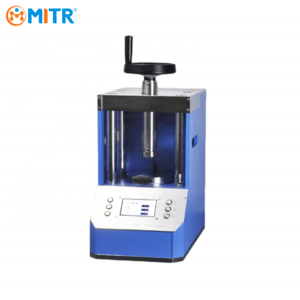

Semi Automatic Compact Powder Lab Pressing Machine for Make up Equipments for Sale

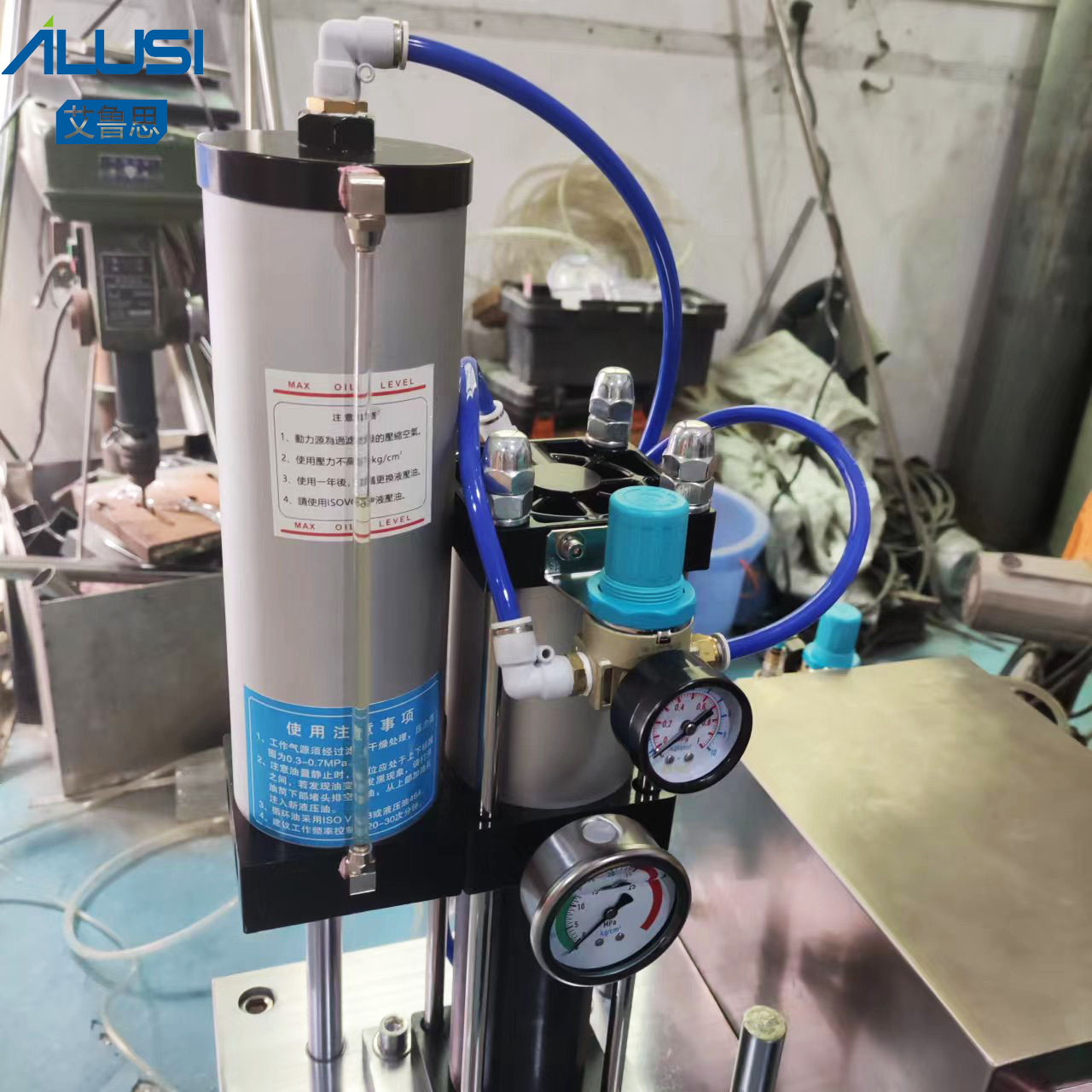

This machine is suitable for the laboratory use of new products in the cosmetics make-up factory. The structure adopts two-stage semi-automatic design, which has the function of holding pressure, stable output and simple and convenient operation. Can be widely used in various types of powder cakes, eye shadow, blush and other products experimental manufacturing.

FEATURES AT A GLANCE

1) The utility model has the advantages of simple structure and convenient operation

2) This model is mainly used as a laboratory test for powder compaction.

3) The output clamping force is 10 tons, the sectional pressure and the two-stage adjustable speed output, and the holding time and the number of pressing can also be set by itself, and the experimental data can be converted into production process parameters.

Product Paramenters

|

Type

|

Lab powder pressing machine

|

Dimension

|

450*450*900mm

|

|

Weight

|

50kg

|

Electric

|

220V/50Hz/Single Phase

|

|

Power

|

20W

|

Safe pressure

|

0-70 KG/CM2

|

|

High pressure

|

140 KG/CM2

|

Production capacity

|

5-10s/mold

|

Machine Application

Details Images

Packing & Delivery

Factory Show

Service & FAQ

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Maintenance service.

FAQ

Q1

: Are you a factory or trading company?

A1

: We are a factory specialized in Vacuum emulsifying mixer, filling machine, RO water treatment, capping machine and labeling machine…etc for cosmetic, pharmaceutical, chemical equipment over 20 years.

Q2

: How does your factory do regarding quality control?

A2

: Quality is priority. We always attach great importance to quality controlling from the beginning to the end. We support to inspect machine before shipment.

Q3

: What’s the guarantee and the after service if we purchase from you?

A3

: All the equipment ordered from us will provide one year guarantee from the delivery date.we could send our engineer to install or fix the machine locally.

Q4

: Are your machines difficult to operate? How do you teach us to use the machine?

A4

: Our machines are easy to operate, before delivery we will shoot instruction video to introduce machines' functions and to teach you how to use them.

Q5

: Can you make the machine according to customers' request?

A5

: Yes of course, OEM is acceptable. Most of our machines are customized design based on customer's requirements or situation.

Successful Project

Project in Austria

Project in USA

Project in Thailand

Hot Searches