- Product Details

- {{item.text}}

Quick Details

-

Max Speed:

-

40cans/min

-

Voltage:

-

380V, 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Utust Pack

-

Dimension(L*W*H):

-

2100*1200*1700 mm

-

Weight:

-

800 KG

-

Product name:

-

Automatic fresh fruit wet foods canning vacuum can seamer

-

Material:

-

Stainless Steel

-

Can sealing speed:

-

30-40 Cans/min

-

Sealing Head:

-

1

-

Vacuum degree:

-

Minus 30-40 KPa

-

Sealing height:

-

30-200mm (adjustable)

-

Air source:

-

0.6-0.8 MPa

Quick Details

-

Packaging Type:

-

CANS, Bottles

-

Packaging Material:

-

Plastic, Metal

-

Driven Type:

-

Electric

-

Max Speed:

-

40cans/min

-

Voltage:

-

380V, 50/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Utust Pack

-

Dimension(L*W*H):

-

2100*1200*1700 mm

-

Weight:

-

800 KG

-

Product name:

-

Automatic fresh fruit wet foods canning vacuum can seamer

-

Material:

-

Stainless Steel

-

Can sealing speed:

-

30-40 Cans/min

-

Sealing Head:

-

1

-

Vacuum degree:

-

Minus 30-40 KPa

-

Sealing height:

-

30-200mm (adjustable)

-

Air source:

-

0.6-0.8 MPa

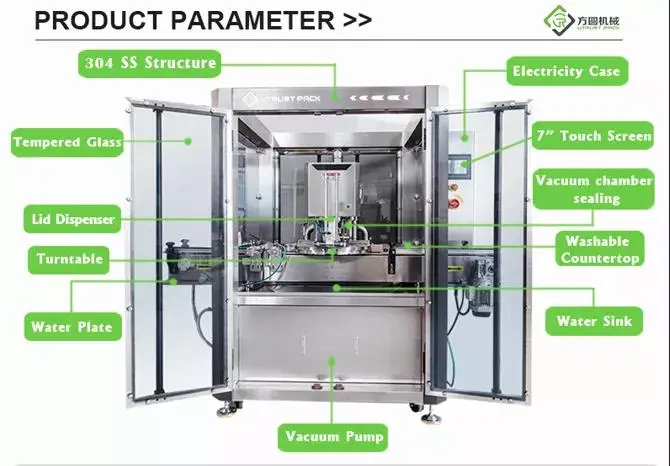

Product description

Automatic commercial fresh fruit wet foods canning vacuum tin metal aluminum can seamer machine

This product is mainly suitable for all kinds of

canned fruit, canned meat, canned pet food, canned seafood, etc

. With advanced design, reasonable structure and simple operation, it is an ideal and necessary packaging equipment for the food, milk powder and chemical industry.

Specification

|

Function

|

High Speed Vacuum tin canning, can seaming, can sealing

|

|

Sealing rollers

|

4(2 first rollers/2 second rollers)

|

|

Sealing Speed

|

30-40 cans/min

|

|

Sealing Height

|

30-200mm (adjustable)

|

|

Sealing Diameter

|

50-100mm (8 station)

|

|

Voltage

|

380V,50/60Hz

|

|

Power

|

4.8KW

|

|

Weight

|

800KG

|

|

Dimension

|

2100*1200*1700mm (L*W*H)

|

|

Air Source Pressure

|

0.6-0.8MPa

|

FEATURE

*

The machine head can be lifted and lowered electrically

without manual adjustment, which is convenient and fast.

* Working

mode: vacuum and sealing i

n the patented design vacuum chamber.

* Real-time monitoring of vacuum degree can be displayed , and vacuum degree can be adjusted as needed.

* Waterproof design , easy to clean by water.

* External electric case with Delta 7-inch touch screen.

* Production capacity: with our new design sealing head .

* Adopt servo motor driven with simple structure, stable operation, and low noise characteristics.

* Turntable automatic reset positioning after initiating.

* Auto stop and alarm function in case of cans stocking within the turntable, to effectively prevent mechanical structure damage.

* One-button reset function for turntable positioning after taking out the cans.

* Easy changing mold function : replace the turntable and the sealing position can be automatically memorized with the one-button setting, to eliminate manual adjustment on the screws for different positions.

* Sealing chuck head and sealing rollers are made with 440C stainless steel material and go through vacuum quenching tempering heat treatment to ensure high hardness and durability.

* Can body does not rotate with good sealing performance.

* Suitable for a variety of cans including plastic cans, tinplate cans, aluminum cans, etc., and widely applicable in food, beverage, and other industries.

* Real-time monitoring of vacuum degree can be displayed , and vacuum degree can be adjusted as needed.

* Waterproof design , easy to clean by water.

* External electric case with Delta 7-inch touch screen.

* Production capacity: with our new design sealing head .

* Adopt servo motor driven with simple structure, stable operation, and low noise characteristics.

* Turntable automatic reset positioning after initiating.

* Auto stop and alarm function in case of cans stocking within the turntable, to effectively prevent mechanical structure damage.

* One-button reset function for turntable positioning after taking out the cans.

* Easy changing mold function : replace the turntable and the sealing position can be automatically memorized with the one-button setting, to eliminate manual adjustment on the screws for different positions.

* Sealing chuck head and sealing rollers are made with 440C stainless steel material and go through vacuum quenching tempering heat treatment to ensure high hardness and durability.

* Can body does not rotate with good sealing performance.

* Suitable for a variety of cans including plastic cans, tinplate cans, aluminum cans, etc., and widely applicable in food, beverage, and other industries.

Show Details

WATER TRAY

1. The entire conveyor belt comes with the stainless steel water tray, which leads the water back to the sink

WATER CHANNEL

1. Water sink with a strainer

2. Wash directly by wate

PETANTED DESIGN SEAMING HEAD

1. Reach higher productivity at lower frequency

TURNTABLE DRIVEN BY SERVO MOTOR

1. Precisely positioning

2. Detect the torque

2. Detect the torque

EXTERNAL ELECTRIC CASE

1. Delta 7 inch touch screen

VACUUM CHAMBER

1. Patented design vacuum chamber,which is able to achieve vacuum at 40 degrees

Applications

This machine is applicable for sealing various round cans including

PET plastic bottles, tinplate cans, aluminum cans, paper cans, and etc.

Customer Feedback

Hot Searches