- Product Details

- {{item.text}}

Quick Details

-

Process:

-

Investment casting/Lost wax

-

Material:

-

Aluminum,stainless steel,carbon steel

-

Dimension:

-

Customized

-

Quality Control:

-

100% inspection

-

Application:

-

Industrial, commercial, Household, Automotive parts

-

Tolerance:

-

+/- 0.02 mm

-

Roughness:

-

ra3.2-ra6.3

-

Package:

-

Wooden pallet

-

Export experience:

-

More than 10 years

-

MOQ:

-

10 Pieces

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

OEM

-

Model Number:

-

As drawing

-

Process:

-

Investment casting/Lost wax

-

Material:

-

Aluminum,stainless steel,carbon steel

-

Dimension:

-

Customized

-

Quality Control:

-

100% inspection

-

Application:

-

Industrial, commercial, Household, Automotive parts

-

Tolerance:

-

+/- 0.02 mm

-

Roughness:

-

ra3.2-ra6.3

-

Package:

-

Wooden pallet

-

Export experience:

-

More than 10 years

-

MOQ:

-

10 Pieces

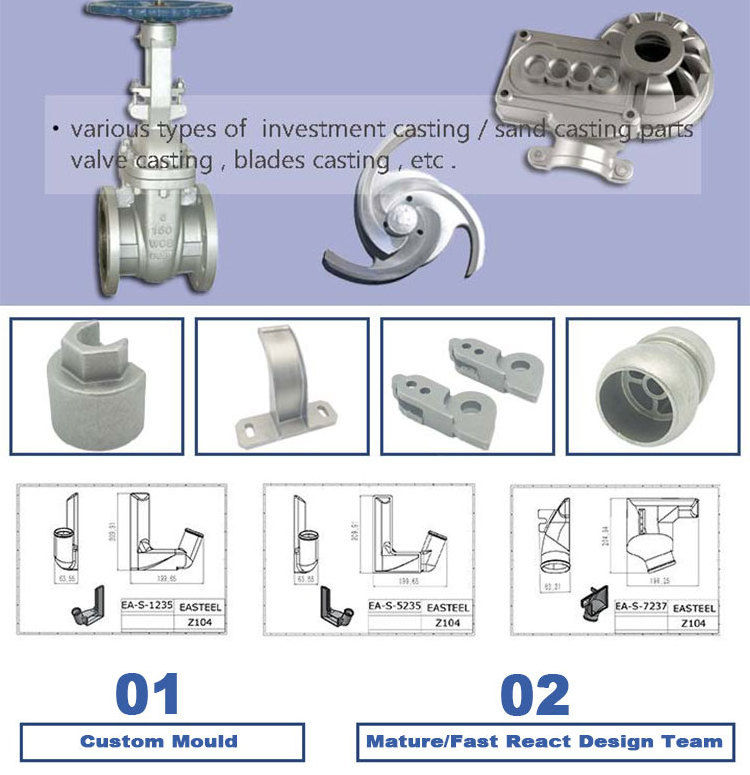

Products Description

We can make brass/steel/stainless steel/aluminum castings with Sand Cast Process, Investment Cast Process, Lost Wax Cast Process, Water Glass Cast Process,Gravity Cast Process.

Gravity Casting / Investment Castng / Lost Wax Casting / Water Glass Casting

Gravity Casting / Investment Castng / Lost Wax Casting / Water Glass Casting

|

Material

|

Carbon steel, Alloy steel, Stainless steel, Aluminium, Copper

|

|

Process

|

Lost wax casting + CNC machining

|

|

Casting tolerance

|

+/- 0.02 mm

|

|

Casting roughness

|

Ra1.6-3.2

|

|

Casting weight range

|

0.005-50kg

|

|

Surface Treatment

|

Zinc plating, Polishing, Anodizing, Painting, Nickel plating

|

|

Service

|

OEM

|

|

Quality Control

|

100% inspection

|

|

Capability

|

Output 100 tons per month.

|

|

Application

|

Industrial, commercial, Household,Automotive parts

|

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

We have a professional engineer team to design custom parts for your remand, we also have a lot of ready-made standard moulds that can save your cost and time . We offer ODM/OEM service, Production Design and Mould Design base on your requirement . Providing the sample before mass production , ensure all is OK for you .

Production Process

Related Products

Our Company

Certificate

FAQ

|

Q1.What do I need for offering a quote ?

|

|

Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement ,quantity, application or samples etc.)Then we will quote the best price within 24h.

|

|

Q2.What's the production time for new molds and mass production?

|

|

7-10 days to make the new moulds, mass production takes around 20-25days,can process urgently if need

|

|

Q3.Can you send me samples ?

|

|

Yes, Samples are for free, and freight is on your side.

|

|

Q4.How long is the lifetime ?

|

|

Anodizing for 12-15 years outdoor, Powder coating for 18-20 years outdoor.

|

|

Q5.What is the payment terms ?

|

|

T/T: 30% deposit, the balance will be paid before delivery;

L/C: the balance irrevocable L/C at sight. |

Hot Searches