- Product Details

- {{item.text}}

Quick Details

-

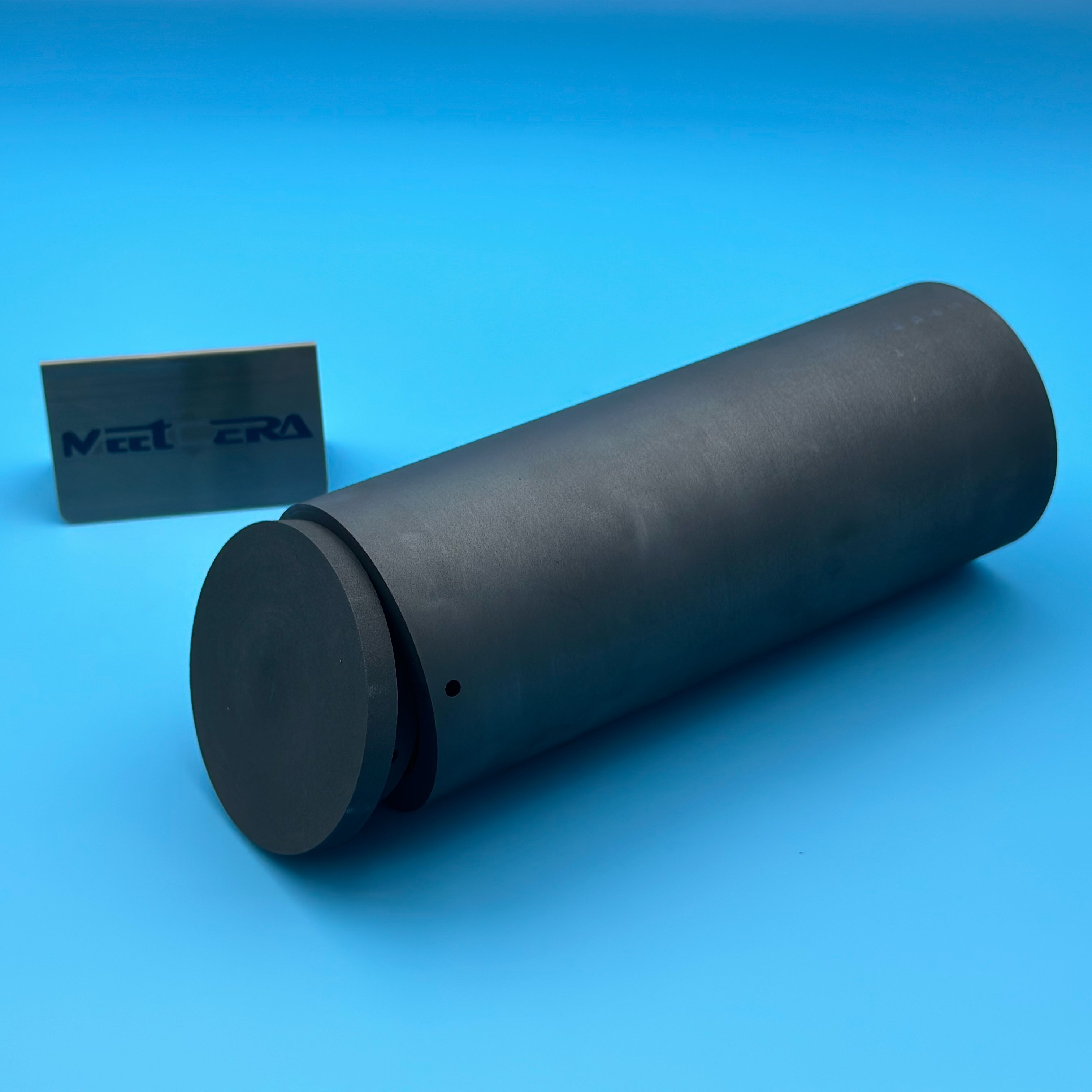

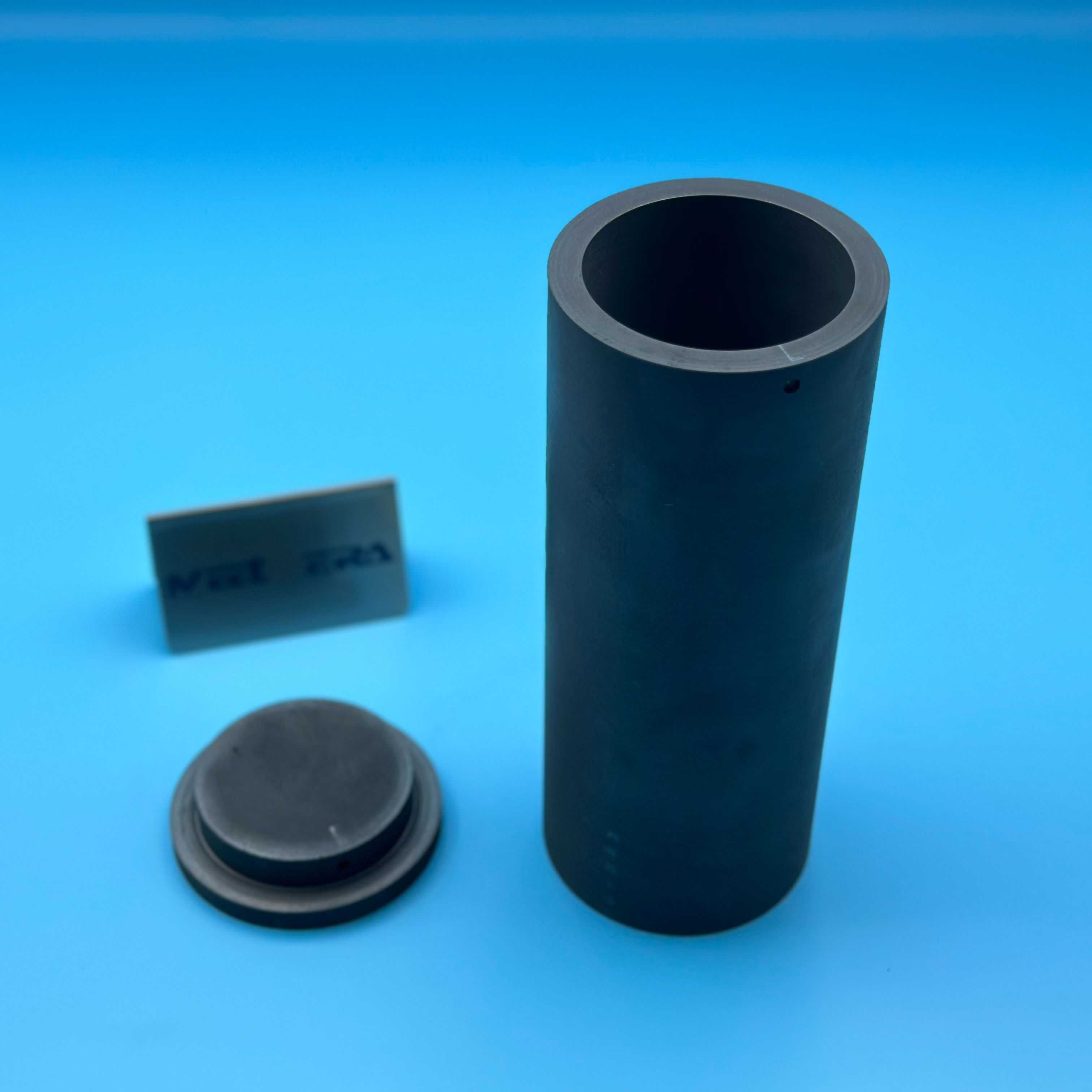

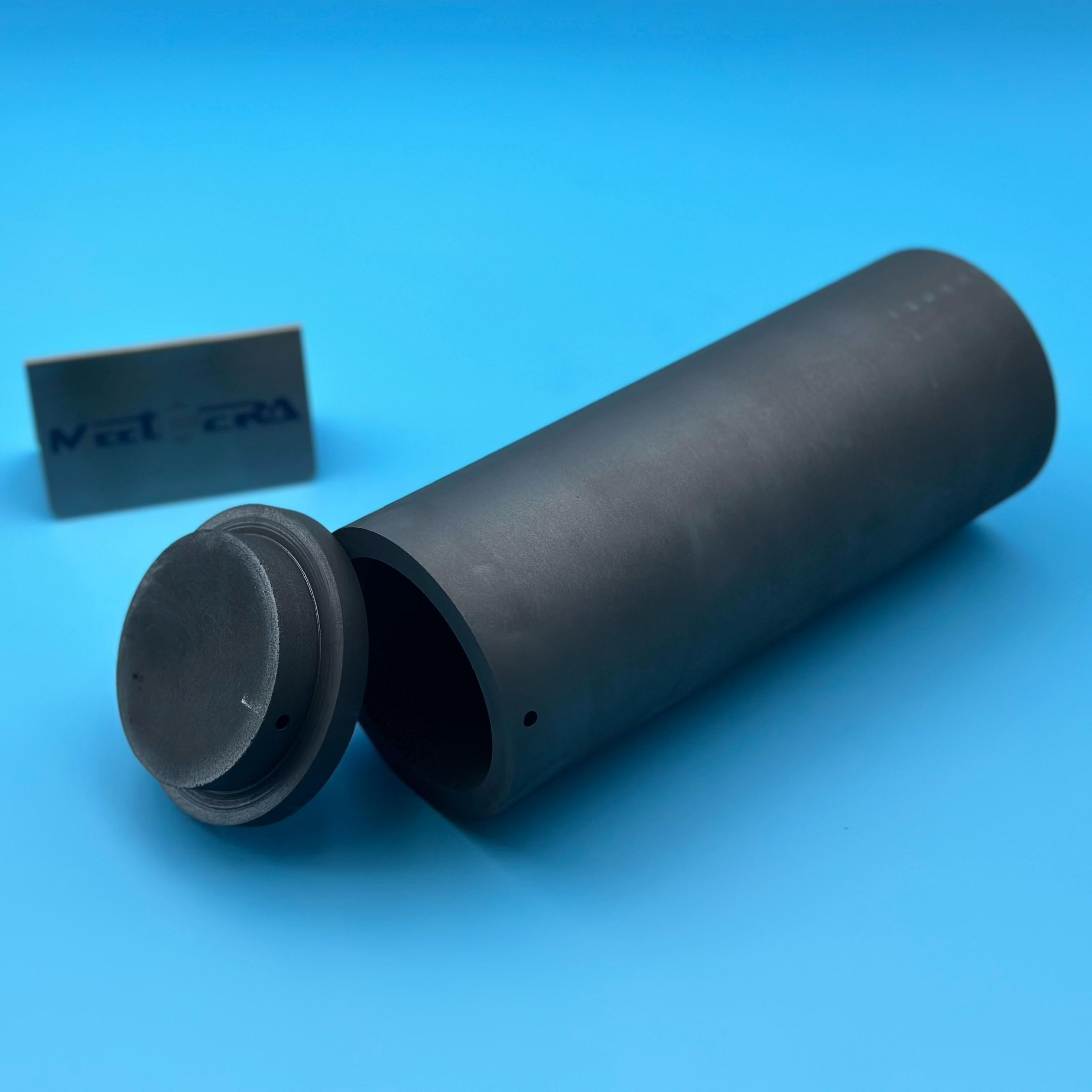

Product name:

-

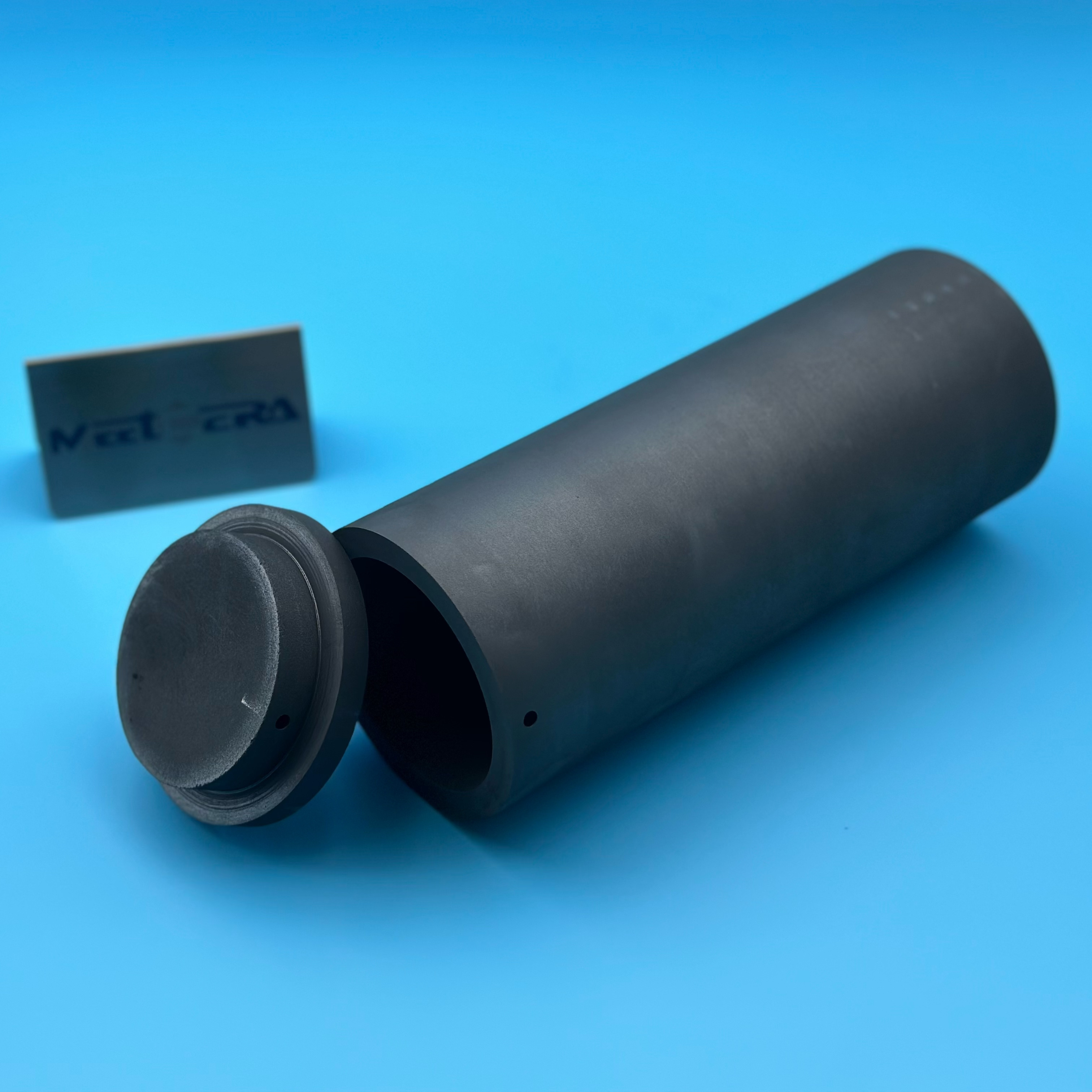

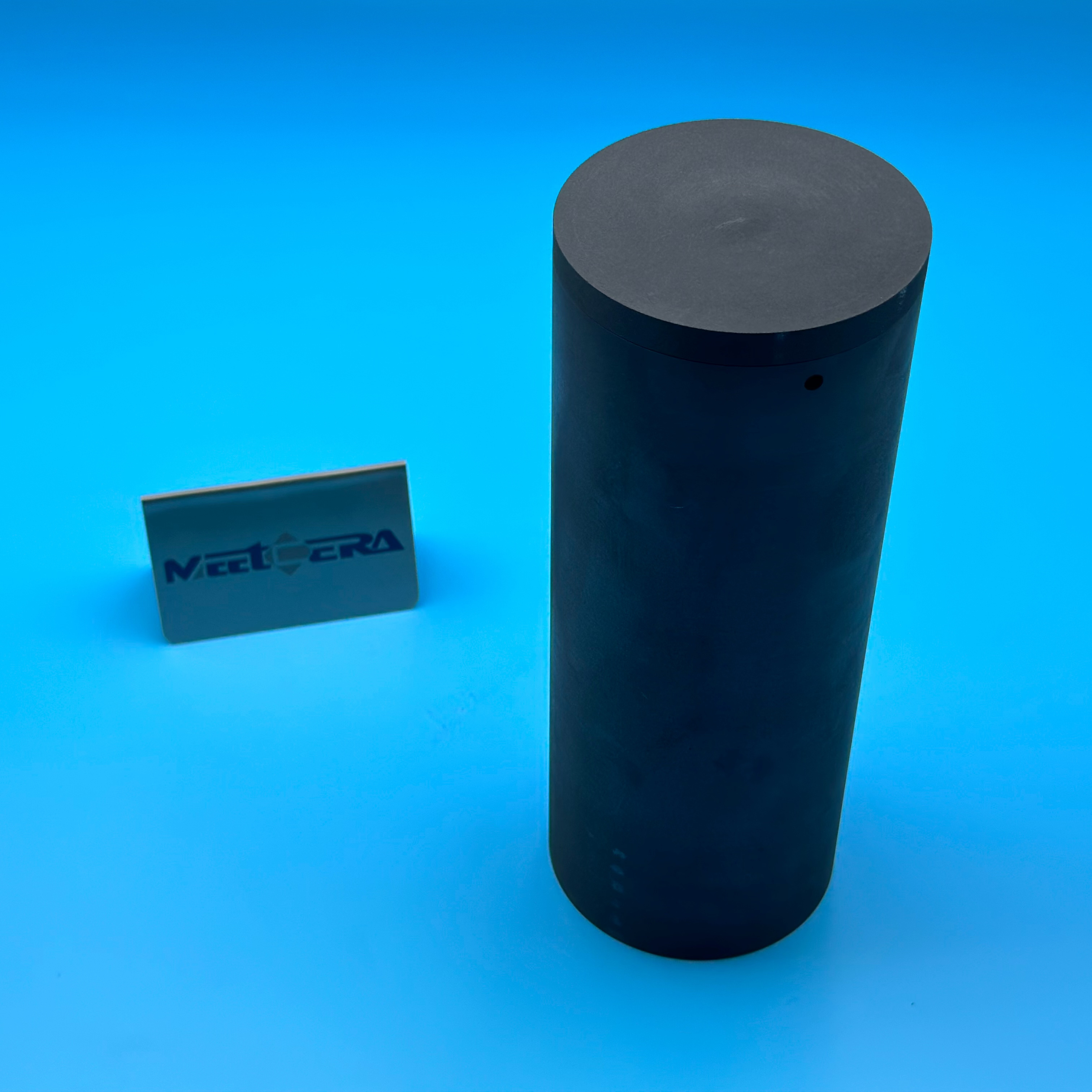

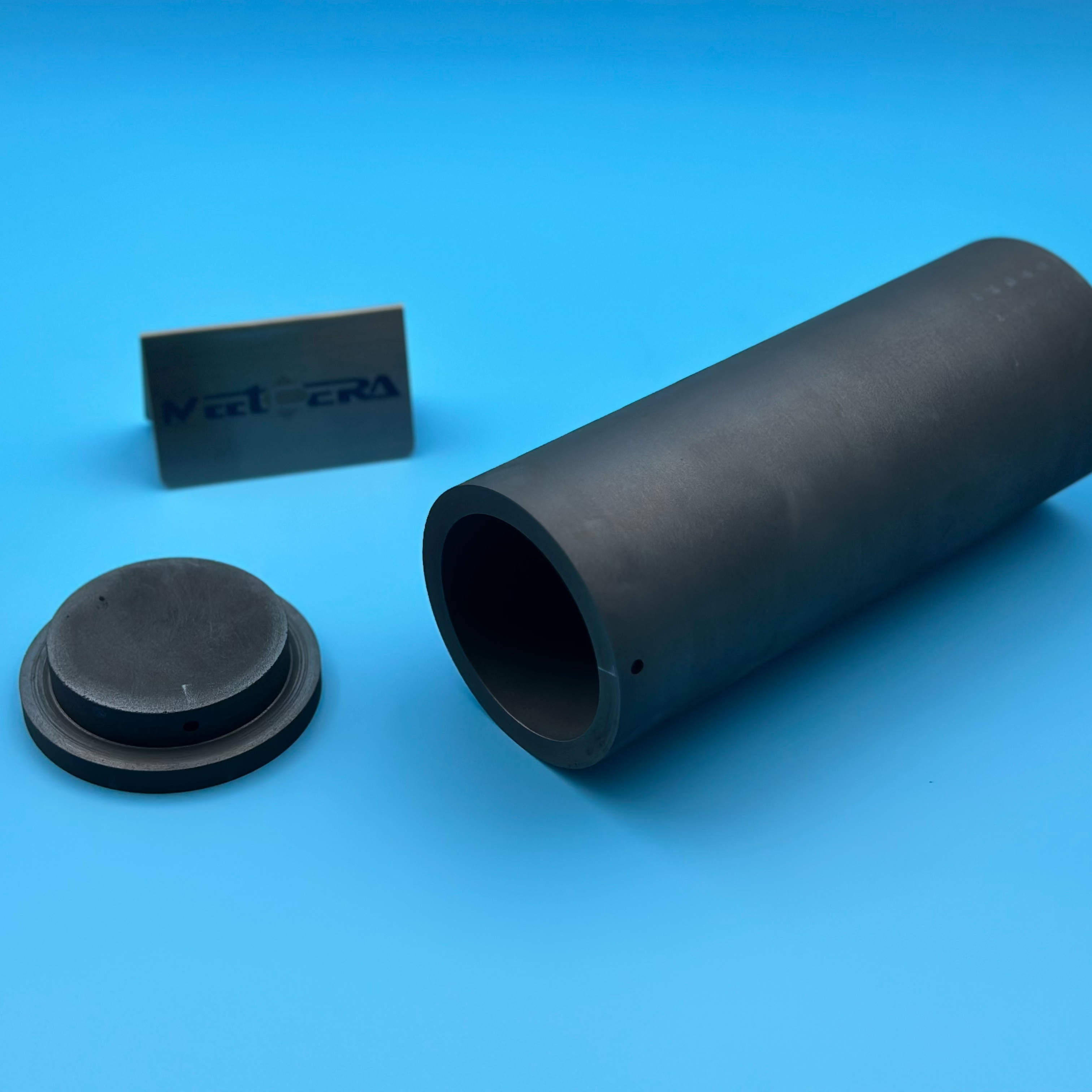

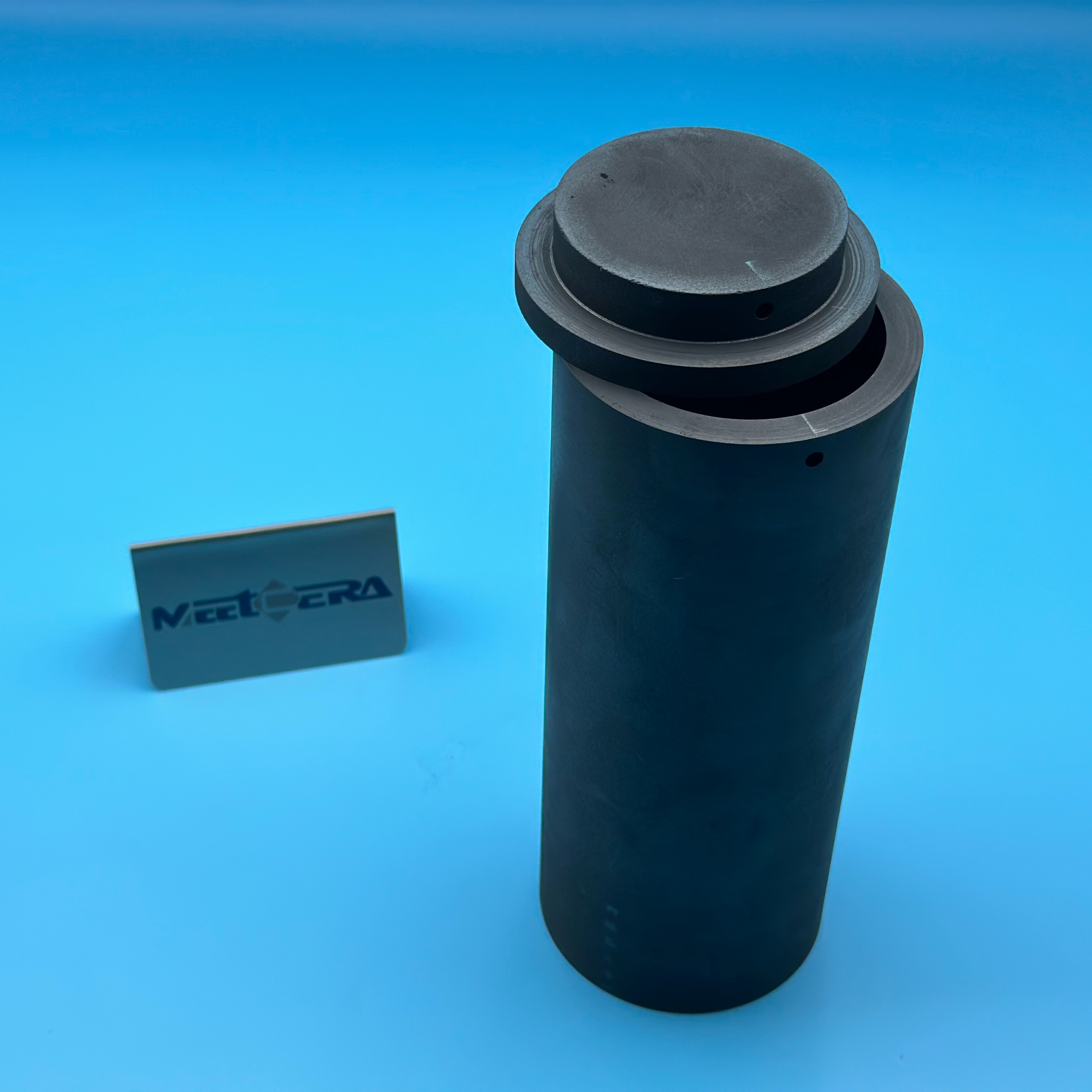

Graphite crucible

-

Height:

-

As requested

-

Composition:

-

High Pure

-

Top Diameter:

-

As requested

-

Bottom Diameter:

-

As requested

-

Color:

-

Black grey

-

Bluk Density:

-

1.77g/cm3

-

Coefficient of Thernal Expansion:

-

≤4.5*10-6

-

Compressive Strength:

-

≥50Mpa

-

Fluxual Strength:

-

≥30Mpa

Quick Details

-

Material:

-

graphite

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

meetcera

-

Product name:

-

Graphite crucible

-

Height:

-

As requested

-

Composition:

-

High Pure

-

Top Diameter:

-

As requested

-

Bottom Diameter:

-

As requested

-

Color:

-

Black grey

-

Bluk Density:

-

1.77g/cm3

-

Coefficient of Thernal Expansion:

-

≤4.5*10-6

-

Compressive Strength:

-

≥50Mpa

-

Fluxual Strength:

-

≥30Mpa

Graphite crucible

Advantage:

1. Good thermal stability: special formula targeting the shock heating and shock cooling use conditions of graphite crucible.

2.Good corrosion resistance and impact resistance performance can ensure the reliability of product quality.

3. Good resistance to strong acid and alkali.

4.Good thermal conductivity can greatly shorten the melting time and save energy.

5.The ash content of graphite crucible is less than 300pp, which can ensure that precious metal is free from pollution during smelting.

6. Widely used in the smelting area, e.g. gold smelting, silver smelting, aluminum smelting, cooper

smelting, etc

2.Good corrosion resistance and impact resistance performance can ensure the reliability of product quality.

3. Good resistance to strong acid and alkali.

4.Good thermal conductivity can greatly shorten the melting time and save energy.

5.The ash content of graphite crucible is less than 300pp, which can ensure that precious metal is free from pollution during smelting.

6. Widely used in the smelting area, e.g. gold smelting, silver smelting, aluminum smelting, cooper

smelting, etc

|

Item

|

Unit

|

High Density

|

High Purity

|

Isostatic Pressing

|

|

Bulk Density

|

g/cm3

|

1.70

|

1.75

|

1.8

|

|

Resistivity

|

μΩ.m

|

8.5

|

10

|

15

|

|

Flexural

|

MPa

|

13

|

37

|

40

|

|

Compressive Strength

|

MPa

|

28

|

45

|

65

|

|

Ash Content

|

%

|

0.5

|

0.1

|

0.3

|

Production Process

Meetcera Ceramic has the whole process of service capabilities in ceramic parts’ research and development, molding, sintering, processing and testing. It can be customized according to your demands, has advantages in quality, delivery time and cost.

Moulding

Sintering

Machining

Testing

Packing&Shipping

Hot Searches