- Product Details

- {{item.text}}

Quick Details

-

Features:

-

6 axis

-

Production Capacity:

-

10 sets/month

-

Warranty:

-

12 months

-

Dimension(L*W*H):

-

1500*1500*2000

-

Power:

-

15kw

-

Voltage:

-

380/3ph

-

Weight (KG):

-

1200

-

Working area:

-

1500*3000*900mm

-

Spindle:

-

HS300 and ES368

-

Inverter:

-

DELTA inverter

-

Control system:

-

Syntec Control System

-

X, Y Transmission:

-

Helical rack gears&pinion

-

Z transmission:

-

3210 TBI ball screw

-

Motor:

-

YASKAWA servo motor

-

Driver:

-

YASKAWA servo driver

-

Reducer:

-

Japanese Shimpo

-

Name:

-

5 axis cnc router

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

UnionTech

-

Application:

-

Wood, stone, foam, mould, statue

-

Features:

-

6 axis

-

Production Capacity:

-

10 sets/month

-

Warranty:

-

12 months

-

Dimension(L*W*H):

-

1500*1500*2000

-

Power:

-

15kw

-

Voltage:

-

380/3ph

-

Weight (KG):

-

1200

-

Working area:

-

1500*3000*900mm

-

Spindle:

-

HS300 and ES368

-

Inverter:

-

DELTA inverter

-

Control system:

-

Syntec Control System

-

X, Y Transmission:

-

Helical rack gears&pinion

-

Z transmission:

-

3210 TBI ball screw

-

Motor:

-

YASKAWA servo motor

-

Driver:

-

YASKAWA servo driver

-

Reducer:

-

Japanese Shimpo

-

Name:

-

5 axis cnc router

Hot Sale Automatic 6 axis industrial kuka spray painting 6 axis kuka robot industrial engraving machine arm robot price

Products Description

This system is suitable for engraving work of various batches of workpieces in industrial production, suitable for cutting, grinding, drilling and other processing of workpieces, and product modeling of wood, stone, aluminum alloy and composite materials. Coordinate the movement with the turning position machine, integrate the USP port, and use the offline programming system to perform complex workpiece processing. The configuration can be changed at will and it is 100% perfectly compatible. It is very suitable for the secondary development of the product by robot automation integration enterprises, with unlimited functions. The robot can work normally even in harsh environments, with a service life of up to 15 years and an average time between accidents as long as 70,000 hours.

The KUKA KR210-R2700 robot is a light-load robot newly launched by KUKA. Its load capacity of 210 kg is especially suitable for carving work. Whether it is installed on the ground or suspended on the ceiling, it can complete the work quickly and efficiently with extremely high continuous track accuracy, and has a working circumference of 3100 mm. In addition, its modular design also makes it an economical solution.

Technical Parameters:

|

Load (refers to the load of point P at the foremost end of the 6th axis)

|

210kgs

|

|

|

|

Additional load on the arm

|

50kgs

|

|

|

|

Total load

|

260kgs

|

|

|

|

Weight

|

1068kgs

|

|

|

|

Motion axis

|

6

|

|

|

|

Max.envelope

|

2696mm

|

|

|

|

Repeat accuracy

|

〈+/-0.06mm

|

|

|

|

Flange (on the 6th axis)

|

DIN ISO 9409-1-A50

|

|

|

|

Controller

|

KRC4

|

|

|

|

Installation position

|

On the ground

|

|

|

|

Motion parameters of each axis

|

Range of motion

|

Speed

|

|

|

Axis 1

|

+/-185°

|

123°/s

|

|

|

Axis 2

|

-5°/-140°

|

115°/s

|

|

|

Axis 3

|

+155°/ -120°

|

112°/s

|

|

|

Axis 4

|

+/-350°

|

179°/s

|

|

|

Axis 5

|

+/-125°

|

172°/s

|

|

|

Axis 6

|

+/-350°

|

219/°/s

|

|

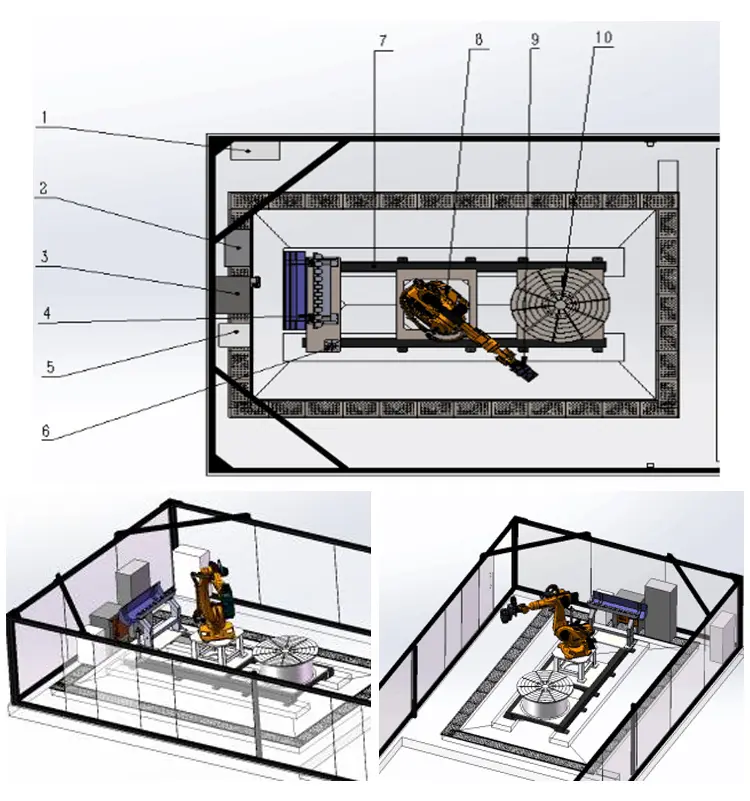

Milling System Integrated

1: Pneumatic control unit

3: Robot control cabinet

5: Cooling unit

7: 7th axis rails(Option)

9: Electric milling spindle

2: Electrical control cabinet

4: Linear tools magazine

6: Tool measurement and detection device

8: Robot body

10: Rotation table(Option)

Machine Details

Italian Hiteco Spindle

1. The electric spindle can adopt high-speed grease and oil mist lubrication according to different speeds.

2. The temperature rise caused by the high-speed rotation of the electric spindle is eliminated by the water cooling circulation system.

3. It has the advantages of high precision, high rigidity, high efficiency, large output power, low noise, etc., and the speed

is 12000 rpm/min.

4. The use of universal HSK F63 standard tool holders can meet customers' quasi-change use of different processing tools.

2. The temperature rise caused by the high-speed rotation of the electric spindle is eliminated by the water cooling circulation system.

3. It has the advantages of high precision, high rigidity, high efficiency, large output power, low noise, etc., and the speed

is 12000 rpm/min.

4. The use of universal HSK F63 standard tool holders can meet customers' quasi-change use of different processing tools.

Teach Pendent

Touch screen, graphics assistance, flexible interaction. The more powerful the robot is, the more important the intuitive robot operation interface is. The new KUKA smartPAD shows how to control the robot intuitively with the best effect on the super high-definition non-reflective touch screen. The intelligent interactive dialog window clearly shows the various processes to the user. At any moment, the user will be provided with the operating elements that they just need at that moment. Its purpose is to draw the user's attention to the most important factors so that it can work intuitively, simply, quickly and effectively. Really realize comprehensive intelligence.

Linear ATC System

The rotary table is a single-axis positioner, which is mainly composed of a positioner frame, a servo drive motor, a precision reducer, a turning plate, a lifting roller frame, a fixture and a control system. Among them, all welded structural parts are assembled by steel plates and profiles. All welds are welded according to the requirements of equal-strength welds. After welding, they are annealed to remove welding stress and effectively prevent processing deformation. The engraving robot composes a 7-axis linkage automatic engraving system, which can greatly increase the size of workpiece engraving and increase labor productivity.

Open KRC4 control system

More efficient, safer, more flexible, and most importantly, more intelligent. The innovative concept of KR C2/C4 has laid a solid foundation for the future of automation. Reduce the integration, maintenance and maintenance costs of automation. And at the same time lastingly improve the efficiency and flexibility of the system. So KUKA has developed a new system architecture with a clear

structure and focusing on the use of open and efficient data standards. All safety control, robot control , motion control, logic control and process control integrated in this system architecture have the same data foundation and foundation Facilities can be used and shared intelligently.

Workspace graphic

Payload diagram

Application Field

Carbon fiber milling

With a robotic system perform the carbon fiber trimming process provides a low level noise and less maintenance periods.

Foam milling

Great programming ability so you can use a variety of tools that shape any material providing profitability in the elimination of

it.

Robotic hot wire cutting

You can perform 2D and 3D modeling on any manageable material with a robotic milling cell, allowing hot wire cutting to provide a perfect and fast finish by polishing.

Marble machining

The marble cut is optimized thanks to the use of robotic systems that offer a tool with greater versatility making the cut with maximum quality and reducing time and effort.

Robot on linear track

Industrial robot on linear track provides greater precision, high speed, self-aligning capability, stiffness and increased performance.

Orthopedic milling

The automation in the medical industry is used diversity of materials such as aluminum, titanium, stainless steel etc ... in this application, the speed and advanced technology offered by the milling and turning system is prime.

Polystyrene milling

The metal milling with industrial robots makes it possible to elaborate large-volume complex parts of small dimensions with high quality and precision.

Robotic art milling

Through a simple interface the robotic arm can shape any wooden surface creating a perfect work of architecture.

Metal machining

The metal milling with industrial robots makes it possible to elaborate large-volume complex parts of small dimensions with high quality and precision.

Milling architecture

Through a simple interface the robotic arm can shape any wooden surface creating a perfect work of architecture.

Robot with rotating table

This is one of the most efficient tools when complementing robotic systems, it provides more degrees of freedom with an external

axis that offers greater safety and maximum quality when executing movements.

axis that offers greater safety and maximum quality when executing movements.

Yacht robot milling

Nautical machining is a challenging task but include industrial robots has become a cost-effective manufacturing solution since through a simulation program can analyze and design the process to be performed with large-scale dimensions.

The Factory To Show

UnionTech Intelligent Milling System is a highly modularized and integrated engraving robot workstation carefully built by UnionTech Co., So far the most integrated and cost-effective engraving robot workstation. It adopts the high-end configuration of the imported top robot manufacturer KUKA KR210 from Germany and its complete set of operation and control systems. The engraving spindle adopts Italian Hiteco high-precision 10KW water-cooled electric spindle, and adopts standard HSK F63 standard tool holder. The tool detection unit adopts Marposs TS30 high-precision tool setting instrument to ensure the accuracy of the processing tool tcp, thereby ensuring the processing quality. The workpiece rotation platform is designed and developed by our company specifically for the robot engraving system, which can be linked with the robot. The software system is the introduction of the international leading robot offline programming system from the AutoDesk company. Robot systems and offline programming systems There is a seamless connection between the two, and it is so meticulously built for only one purpose, to make the robot engraving programming easier, the product production more economical, and the product processing adaptability is better.

Packing Shipping

Hot Searches