Sound proof car damping sheet is based on the material of rubber not flake adhesive material, is applicable to commercial vehicle noise reduction. Non-toxic, odorless, non corrosive, Meet the Emission Test and Requirement for the Materials and Components in

Vehicle; Good self-adhesive, convenient using.

- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Car butyl sound deadener

-

Usage:

-

car, automobile body

-

Thickness:

-

1MM-2MM

-

Width:

-

20MM-1000MM

-

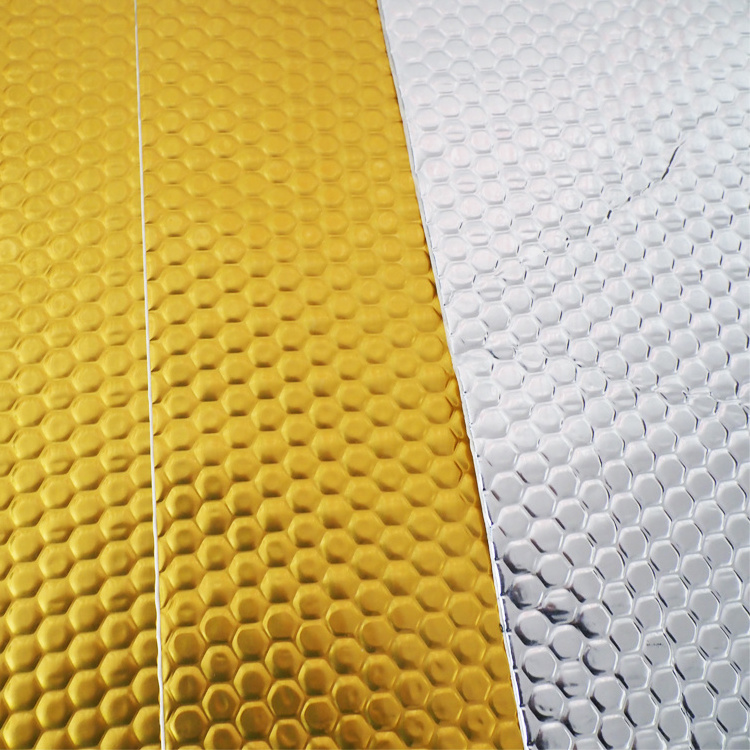

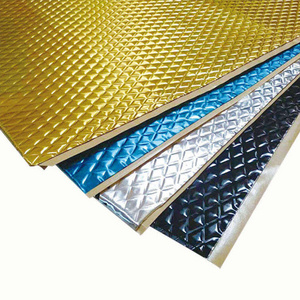

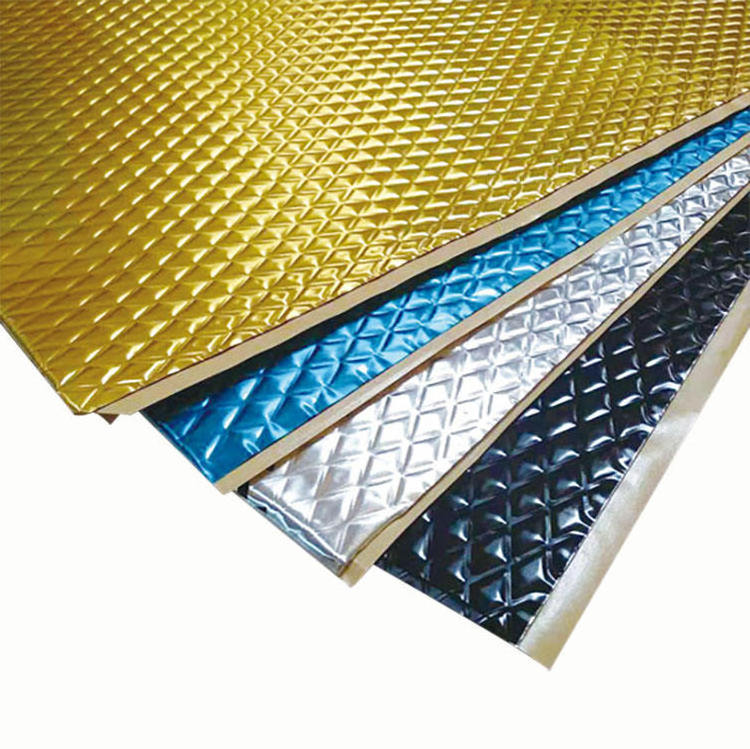

Color:

-

silver white and other colors can be customized

-

Packing:

-

carton pallet

-

MOQ:

-

1500rolls

-

Function:

-

Sealing, dumping and insulation

-

Key words:

-

self-adhesive

-

Base Material:

-

aluminium

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZHB OR OEM

-

Model Number:

-

butyl rubber sound deadening mat

-

Product Name:

-

Car butyl sound deadener

-

Usage:

-

car, automobile body

-

Thickness:

-

1MM-2MM

-

Width:

-

20MM-1000MM

-

Color:

-

silver white and other colors can be customized

-

Packing:

-

carton pallet

-

MOQ:

-

1500rolls

-

Function:

-

Sealing, dumping and insulation

-

Key words:

-

self-adhesive

-

Base Material:

-

aluminium

Product video

Specification

|

Butyl Rubber Technical Data

|

Butyl sound deadening

|

|

|

Items

|

Specifications

|

|

|

1.Permanent Adhesion (min)

|

120min

|

|

|

2. Heat Resistance (160°C 4h)

|

No flowing, cracking or deformation

|

|

|

3. Low Temperature Flexibility(-40°C )

|

No crack

|

|

|

4. Peeling Strength (N/mm)

|

≥0.8

|

|

|

5.Elongation (%)

|

≥500

|

|

|

6. Density g/ cm3

|

≥1.57

|

|

|

7.Penetration 1/10mm

|

35

|

|

|

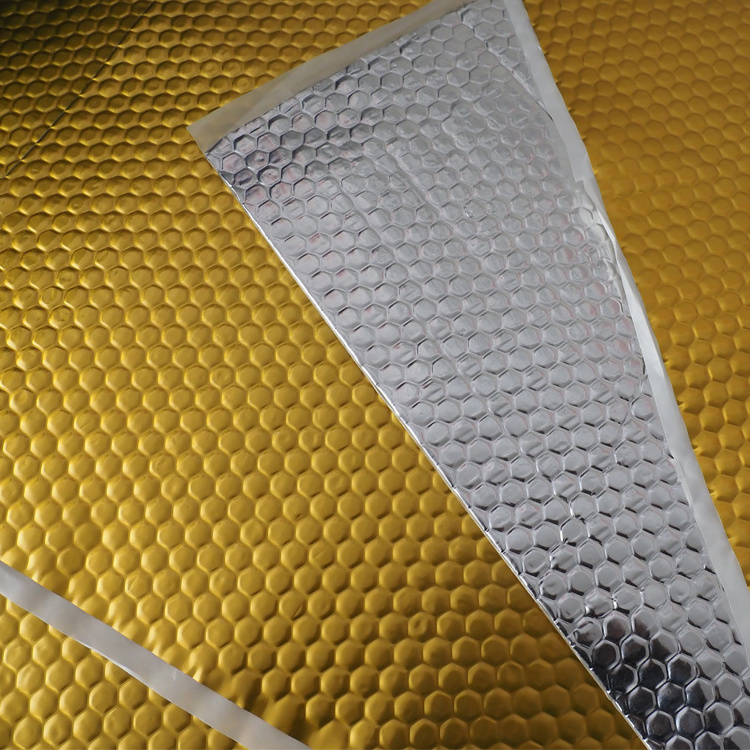

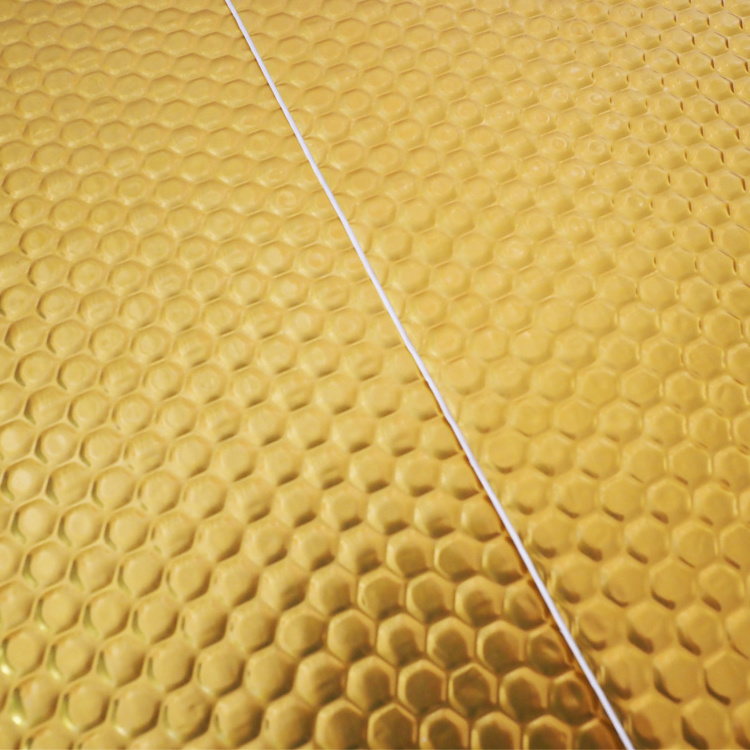

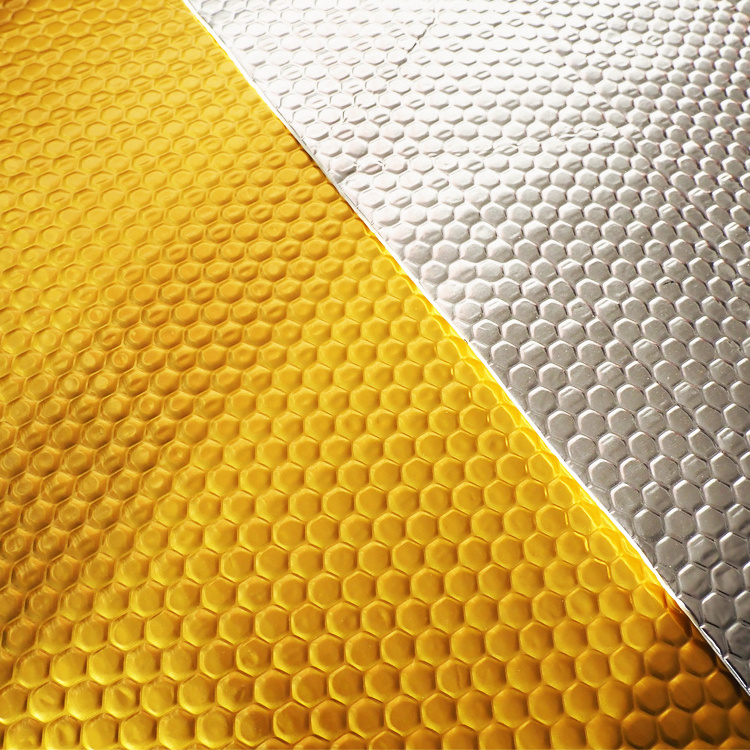

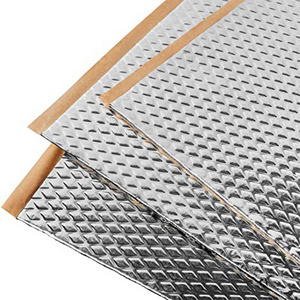

PRODUCT STRUCTURE& PROPERTY

|

|

|

|

Surface Film

|

|

|

|

Aluminum film,Release Paper

|

|

|

|

Damping Butyl Block

|

|

|

|

The self-adhered glue in Butyl Rubber is a kind of good viscoelastic damping material with excellent vibration reduction, noise reduction, and mute and sealing functions.

|

|

|

|

The Characteristics Of Butyl Rubber

|

|

|

|

Fire-Resistant,High Damping,Flexible,Non-Toxic,Odorless,Viscous Strong,Green

|

|

|

Soundproofing materials

Functions

Release the structure transmission attenuation vibration energy

Decrease Vibration and Heat From the engine

Decrease Interior (speaker and car body), Engine, Exhaust Noise, and Vibration.

Reduce External noise (tires on the road, other cars, wind, etc)

Lessen the vibration of the structure shaking or the striking

Release the structure transmission attenuation vibration energy

Decrease Vibration and Heat From the engine

Decrease Interior (speaker and car body), Engine, Exhaust Noise, and Vibration.

Reduce External noise (tires on the road, other cars, wind, etc)

Lessen the vibration of the structure shaking or the striking

Increase the value of your vehicle

Increase your car audio sound effect, make you better music!

Enjoyed you a Cool, Quiet and Comfortable ride

Increase your car audio sound effect, make you better music!

Enjoyed you a Cool, Quiet and Comfortable ride

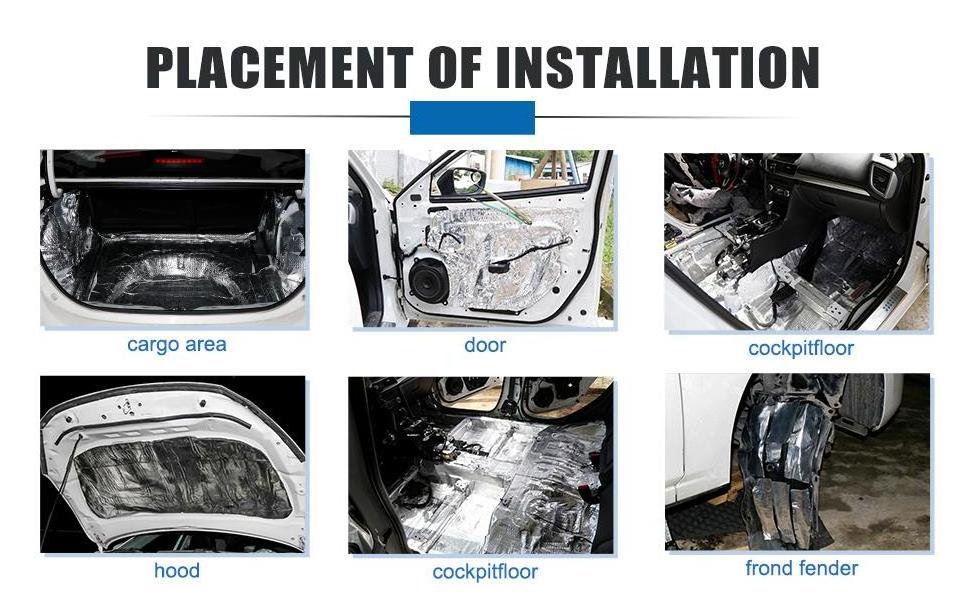

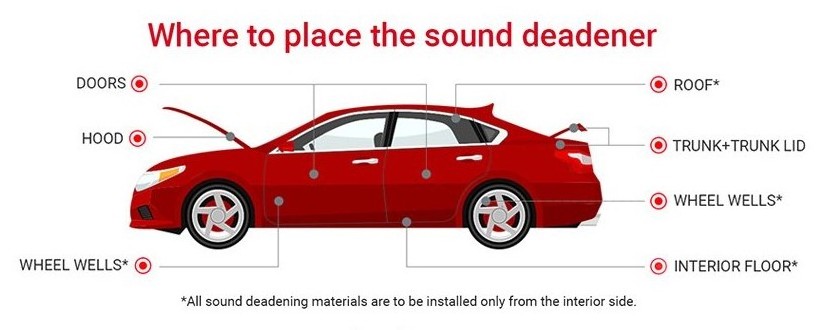

Application

How To Use?

Decide

Decide what parts of the car you want to insulate first: roof, floor, doors, trunk, firewall, or hood. Insulating each part of the vehicle has its benefits. You likely need to do a little detective work to identify the noisiest parts of your car or truck. For

the best results, you’ll need to soundproof all of your vehicle’s metal surfaces. Before installing any material though, step #1 is always to expose the sheet metal. For any metal surfaces behind plastic panels or upholstery, you’ll need to research how to remove them. Be careful to avoid breaking plastic trim parts or any fasteners. Detailed step-by-step guides can be found on our

website or the one of the many automotive forums.

the best results, you’ll need to soundproof all of your vehicle’s metal surfaces. Before installing any material though, step #1 is always to expose the sheet metal. For any metal surfaces behind plastic panels or upholstery, you’ll need to research how to remove them. Be careful to avoid breaking plastic trim parts or any fasteners. Detailed step-by-step guides can be found on our

website or the one of the many automotive forums.

Remove

Remove any damaged factory insulation after you’ve dismantled the interior. If the insulation is in good shape, you can choose to

leave it and save yourself the trouble. Ensure all debris, rust, and waxy oils are removed from the application surface. Clean the

surface with denatured alcohol and a dry, clean rag. We do not recommend using a solvent or degreaser, as they can leave behind a film that will prevent the best bond from forming. Allow the metal to dry.

leave it and save yourself the trouble. Ensure all debris, rust, and waxy oils are removed from the application surface. Clean the

surface with denatured alcohol and a dry, clean rag. We do not recommend using a solvent or degreaser, as they can leave behind a film that will prevent the best bond from forming. Allow the metal to dry.

Measure

Measure the cleaned surface where you want to apply your sound deadener. We recommend to start by making a pattern of an

appropriate size on paper or cardboard and then transfer that to the sound deadening sheet. Taking the time to measure will give

you a cleaner install and avoid wasting material. Use a sharp utility knife to trim the mat to the appropriate size. Our annealed

foil constraint layer is sturdy, so we do not recommend scissors. Be careful and wear gloves. The foil edges are sharp.

appropriate size on paper or cardboard and then transfer that to the sound deadening sheet. Taking the time to measure will give

you a cleaner install and avoid wasting material. Use a sharp utility knife to trim the mat to the appropriate size. Our annealed

foil constraint layer is sturdy, so we do not recommend scissors. Be careful and wear gloves. The foil edges are sharp.

Install

Hold the mat up to the metal surface of the vehicle where you’ll be applying it. Make sure you like the coverage before removing

the wax paper and exposing the tacky butyl adhesive. For larger sheets, it can be easier to gradually remove the paper backing and

slowly work your way across the panel. Use your hands to flatten the sheet and adhere it to the metal surface before rolling out

any air pockets with a wooden hand roller. Pop any stubborn air bubbles with a pin. After you’ve smoothed out the butyl sheet with

the roller, you’ve created a permanent bond that’ll stay stuck even under extreme conditions.

the wax paper and exposing the tacky butyl adhesive. For larger sheets, it can be easier to gradually remove the paper backing and

slowly work your way across the panel. Use your hands to flatten the sheet and adhere it to the metal surface before rolling out

any air pockets with a wooden hand roller. Pop any stubborn air bubbles with a pin. After you’ve smoothed out the butyl sheet with

the roller, you’ve created a permanent bond that’ll stay stuck even under extreme conditions.

OEM Service

Certifications

About Us

Nantong Zhonghao Adhesive Products Co., Ltd. was founded in 2012, which is specialized in products of

all tapes. Butyl sealant tapes and butyl waterproofing membrane.

The tapes with high-quality performance, widely used in construction and residential waterproofing, roofing, window-door, automotive sealing, industrial waterproofing.etc. Also,

we export filament tapes, aluminum tapes, PVC tapes, and other adhesive tapes.

Packing & Delivery

Releated Products

FAQ

Q: Are you a manufacturer?

A: We are an ISO-certified manufacturer with more than 10 years of experience. Our factory is located in Rugao City, one hour from Shanghai by Railway.

Q: What is your factory advantage?

A:1.Professional adhesive tapes manufacturer for almost 10 years.

2. Alibaba assessed Gold Supplier

3. OEM/ODM AVAILABLE

4. Accept small MOQ

5. Good production capacity and fast delivery

Q: Do you accept OEM or ODM services?

A: We can arrange the production as per customers' requirements. We offer free printing both in packing and production. We have massive experience in designing which can satisfy your requirement.

Q: How about the sampling process?

A: Normally we provide free samples for regular products. Sample freight cost bear by your side which can be refunded when you place the mass order.

Q: How do you guarantee the quality?

A: We are making tapes strictly according to ISO. Normally we start production before the customer confirms the sample.

Hot Searches